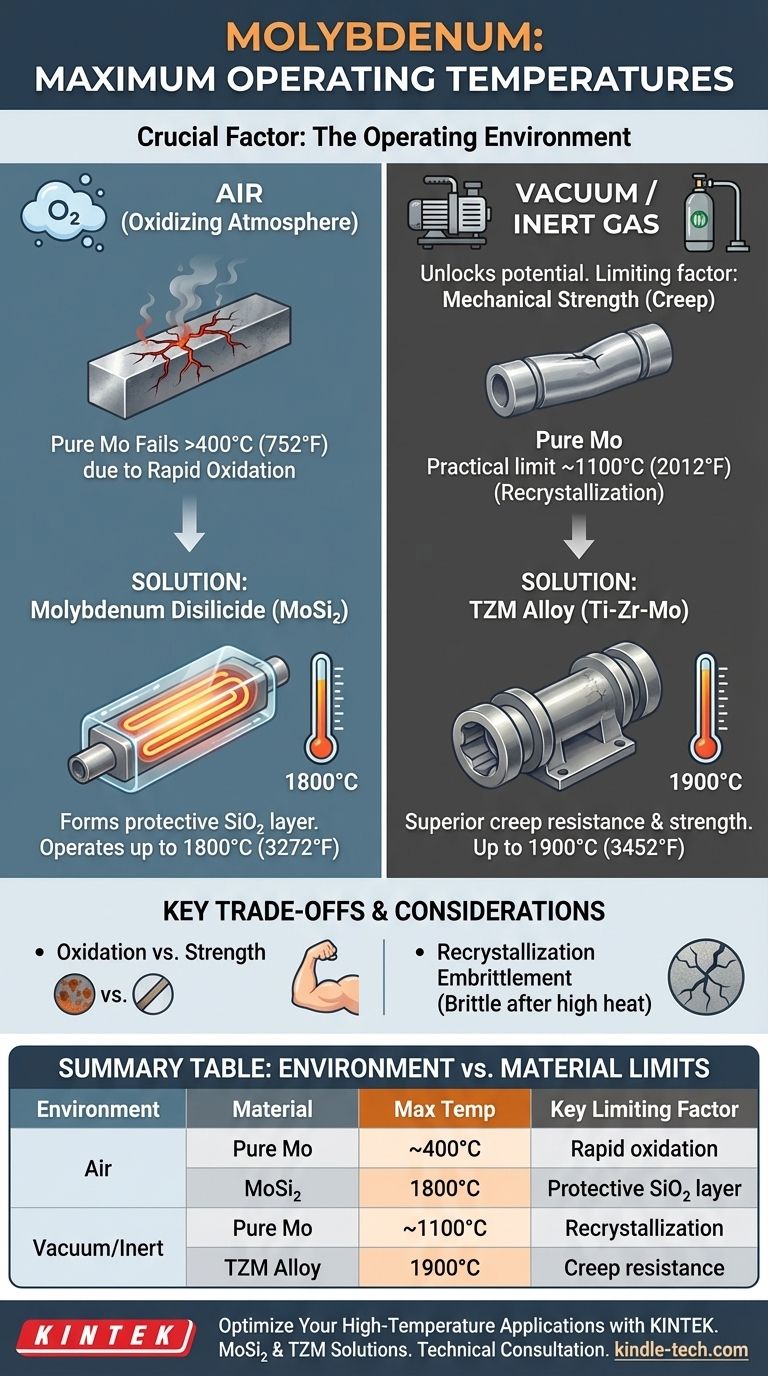

The maximum operating temperature of molybdenum is not a single value; it depends entirely on the operating environment and the specific form of the material being used. In a vacuum or inert atmosphere, molybdenum alloys can operate up to 1900°C (3452°F), but in open air, pure molybdenum begins to fail rapidly above 400°C (752°F). Specialized compounds like Molybdenum Disilicide (MoSi2) are required to reach temperatures of 1800°C (3272°F) in an air environment.

Molybdenum’s exceptionally high melting point is often overshadowed by its poor performance in oxygen. Therefore, the practical temperature limit is defined not by melting, but by the material’s resistance to oxidation and its mechanical strength at temperature.

The Critical Factor: Atmosphere's Impact

The single most important variable determining molybdenum's performance is the atmosphere in which it operates. The difference between its capability in a vacuum versus in open air is not minor—it's the primary design constraint.

Operation in Air (Oxidizing Atmosphere)

Pure molybdenum cannot be used for high-temperature applications in the presence of oxygen. It begins to oxidize at approximately 400°C (752°F).

This oxidation accelerates dramatically with heat, and above roughly 795°C (1463°F), it forms a volatile oxide (MoO₃) that quickly sublimates, causing the material to literally evaporate and fail catastrophically.

The MoSi₂ Solution for Air

To overcome this limitation, molybdenum is compounded with silicon to create Molybdenum Disilicide (MoSi₂), a ceramic-like material used in high-temperature heating elements.

When heated in air, the MoSi₂ forms a thin, protective outer layer of silicon dioxide (SiO₂), or quartz glass. This layer prevents oxygen from reaching the underlying material, allowing it to function reliably at temperatures up to 1800°C.

Operation in Vacuum or Inert Gas

In a non-oxidizing environment, such as a high vacuum or an inert gas like argon, molybdenum's true potential is unlocked.

Without oxygen, the limiting factor is no longer oxidation but the material's mechanical strength and resistance to "creep"—the tendency to slowly deform under stress at high temperatures. This is where specific molybdenum alloys become critical.

Pure Molybdenum vs. Its Alloys

The term "molybdenum" often refers to a family of materials, not just the pure element. Alloying dramatically improves its high-temperature properties.

Pure Molybdenum

Pure molybdenum has a very high melting point of 2623°C (4753°F), but its structural usefulness is much lower.

It begins to lose significant strength and can recrystallize at temperatures above 900°C, making it brittle once cooled. For applications like furnace boats, its practical limit is often cited around 1100°C.

TZM Alloy (Titanium-Zirconium-Molybdenum)

TZM is the premier high-temperature structural alloy of molybdenum. Small additions of titanium and zirconium create a fine dispersion of carbides within the metal.

This structure significantly raises the recrystallization temperature and dramatically improves creep resistance and strength at high temperatures. This allows TZM components to be used effectively up to 1900°C in a vacuum.

Lanthanated Molybdenum (ML)

Lanthanated Molybdenum is another enhanced alloy where microscopic particles of lanthanum oxide are dispersed within the metal.

Similar to TZM, this raises the recrystallization temperature and improves ductility after use, making it more robust and resistant to fracture at room temperature after being exposed to high heat.

Understanding the Trade-offs

Choosing the right material requires balancing its strengths against its inherent weaknesses.

Oxidation vs. Strength

The primary trade-off is between oxidation resistance and mechanical properties. MoSi₂ offers exceptional performance in air but is brittle and has limited use as a structural material. TZM has outstanding strength at high temperatures but is completely dependent on a vacuum or inert environment.

Brittleness After Use

Nearly all forms of molybdenum suffer from a phenomenon known as recrystallization embrittlement. After being heated to a high temperature, the material's grain structure changes, making it extremely brittle at room temperature. This must be factored into the design and handling of any components.

Cost and Machinability

Molybdenum and its alloys are expensive and more difficult to machine than common steels. The material's hardness and a tendency to create abrasive oxides make tooling wear a significant consideration in manufacturing.

Making the Right Choice for Your Application

To select the correct material, you must first define your operating environment and primary performance goal.

- If your primary focus is high-temperature operation in an air environment: Choose Molybdenum Disilicide (MoSi₂) heating elements, as they are specifically designed to resist oxidation.

- If your primary focus is structural strength in a vacuum or inert atmosphere: Choose TZM alloy for its superior creep resistance and higher use temperature compared to pure molybdenum.

- If your primary focus is a general-purpose application in a vacuum below 1100°C: Pure molybdenum can be a cost-effective option where maximum high-temperature strength is not the limiting factor.

Ultimately, selecting the right molybdenum material depends less on its theoretical melting point and more on a clear understanding of your operating atmosphere and mechanical requirements.

Summary Table:

| Environment | Material | Max Operating Temperature | Key Limiting Factor |

|---|---|---|---|

| Air (Oxidizing) | Pure Molybdenum | ~400°C (752°F) | Rapid oxidation and failure |

| Air (Oxidizing) | Molybdenum Disilicide (MoSi₂) | Up to 1800°C (3272°F) | Protective SiO₂ layer prevents oxidation |

| Vacuum/Inert Gas | Pure Molybdenum | ~1100°C (2012°F) | Recrystallization and brittleness |

| Vacuum/Inert Gas | TZM Alloy | Up to 1900°C (3452°F) | Creep resistance and mechanical strength |

Optimize Your High-Temperature Applications with KINTEK

Choosing the right molybdenum material is critical for your lab's high-temperature processes. Whether you need robust heating elements for air environments or high-strength structural components for vacuum furnaces, KINTEK has the expertise and products to meet your specific requirements.

We provide:

- Molybdenum Disilicide (MoSi₂) Heating Elements for reliable operation up to 1800°C in air

- TZM Alloy Components for superior strength and creep resistance in vacuum/inert atmospheres

- Technical Consultation to help you select the optimal material based on your operating environment and performance goals

Don't let material limitations compromise your research or production. Our team specializes in lab equipment and consumables, ensuring you get the right solution for your high-temperature challenges.

Contact KINTEK today to discuss your application requirements and discover how our molybdenum solutions can enhance your lab's capabilities and efficiency.

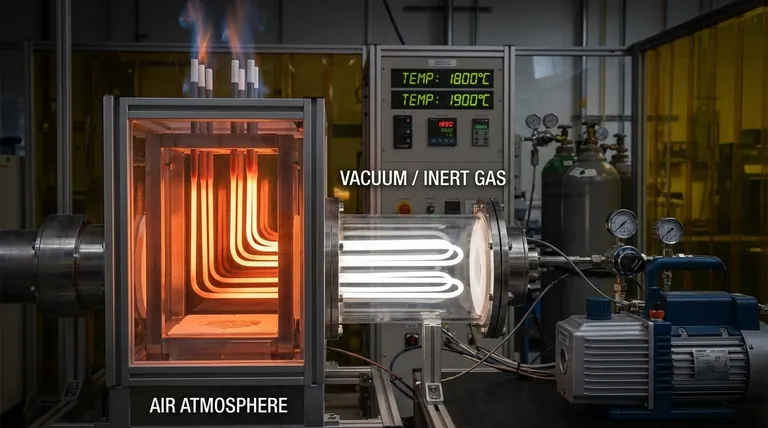

Visual Guide

Related Products

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Advanced Engineering Fine Ceramics Low Temperature Alumina Granulation Powder

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the difference between pyrolysis and plasma gasification? A Guide to Advanced Thermal Conversion

- How is heat transferred in empty space? Discover the Power of Thermal Radiation

- How does a vacuum diffusion bonding furnace ensure the connection quality of titanium laminates? Achieve Superior Bonds

- What critical role does a halogen infrared heating furnace play in converting TiO2 to TiN? Optimize Your RTN Process

- How long does it take to anneal metal? From minutes to days for perfect results.

- Why is a vacuum furnace with flexible pressure control essential for titanium alloy laminates? Achieve Atomic-Level Fusion

- How does a vacuum drying oven benefit Al2O3-TiCN/Co-Ni slurry processing? Protect Material Integrity & Purity

- What is the best braze for aluminum? Master the Al-Si System for Strong, Reliable Joints