At its core, graphene growth via Chemical Vapor Deposition (CVD) is a surface-catalyzed process. It involves feeding a carbon-containing gas, such as methane, into a high-temperature chamber where it decomposes upon contact with a metal catalyst, typically a copper foil. The resulting carbon atoms then diffuse across the metal surface and self-assemble into a continuous, single-atom-thick sheet of graphene.

The key to understanding CVD for graphene is realizing the metal substrate is not a passive surface but an active catalyst. It dramatically lowers the energy required for the reaction, orchestrating how carbon precursors break down and how individual carbon atoms arrange themselves into a high-quality crystalline layer.

The CVD Process: A Step-by-Step Breakdown

The growth of a graphene film is a highly controlled, multi-stage process. Each step is critical for determining the final quality, continuity, and properties of the material.

Step 1: Adsorption and Decomposition

The process begins when precursor gas molecules (e.g., methane, CH₄) are introduced into the reactor and adsorb, or "stick," to the heated catalyst surface.

At temperatures around 1000 °C, the catalyst provides an active site that breaks the chemical bonds of the precursor gas. This decomposition, or pyrolysis, releases carbon atoms onto the surface.

Step 2: Diffusion and Nucleation

Once freed, these individual carbon atoms are not stationary. They diffuse or "skate" across the catalyst surface.

As they move, they occasionally collide and form small, stable carbon clusters. These clusters act as the initial "seeds," or nucleation sites, for graphene crystal growth.

Step 3: Crystal Growth and Coalescence

After nucleation, subsequent carbon atoms diffusing across the surface attach to the edges of these initial graphene islands.

This process of edge attachment causes the islands to grow larger. Over time, these growing islands expand until they meet and merge, forming a continuous, polycrystalline graphene sheet that covers the entire catalyst surface.

The Role of the Catalyst

The catalyst is the most critical component in the CVD process, making graphene synthesis feasible at practical temperatures and defining the quality of the final film.

Why a Catalyst is Non-Negotiable

Without a catalyst, the formation of a graphitic structure from carbon atoms requires temperatures exceeding 2500°C. Such conditions are energetically expensive and difficult to manage.

The metal catalyst dramatically lowers this energy barrier, enabling both the decomposition of the precursor gas and the formation of the graphene lattice at a much more manageable ~1000°C.

The Importance of Catalyst Choice

The most common catalysts are copper (Cu) and nickel (Ni). Copper is particularly favored for single-layer graphene because it has very low carbon solubility.

This low solubility means the reaction is self-limiting; once the copper surface is covered with a single layer of graphene, the catalytic activity ceases, effectively preventing the growth of additional layers.

Surface Quality Determines Graphene Quality

The final quality of the graphene is directly tied to the state of the catalyst. Factors like the catalyst's crystallinity, specific crystal facet exposed, and surface roughness all influence nucleation density and growth. A smoother, more uniform catalyst surface generally leads to higher-quality, more uniform graphene.

Understanding the Key Trade-offs

Achieving high-quality graphene is a balancing act. The process parameters must be precisely controlled to avoid common pitfalls that degrade the material.

The Danger of Gas-Phase Reactions

The decomposition of the hydrocarbon precursor must occur on the hot catalyst surface (a heterogeneous reaction).

If the temperature is too high or the gas pressure is incorrect, the precursor can decompose in the gas phase before ever reaching the substrate. This forms amorphous carbon soot, which then falls and contaminates the surface, creating defects and ruining the graphene quality.

Balancing Growth Speed and Quality

The process conditions—temperature, pressure, and gas flow rates—are levers that control the growth kinetics.

Rapid growth, driven by high precursor flux, can lead to a higher density of nucleation sites and faster coverage. However, this often comes at the cost of smaller crystal domains and more defects. Conversely, slower, more controlled growth yields higher-quality graphene but is less efficient.

Making the Right Choice for Your Goal

Your specific objective dictates which process parameters you should prioritize.

- If your primary focus is the highest possible electronic quality: Prioritize a high-purity, ultra-smooth catalyst and use a low precursor flow rate to encourage slow, steady growth of large graphene crystals with minimal defects.

- If your primary focus is process scalability for applications like transparent conductors: Optimize for the fastest growth rate possible that still avoids gas-phase soot formation, accepting a higher density of grain boundaries.

- If your primary focus is fundamental research: Experimenting with different catalyst alloys, crystal orientations, and precursor gases is key to discovering new ways to control nucleation density and defect formation.

Ultimately, mastering graphene CVD is about precisely controlling the environment on the catalyst surface to guide carbon's transformation from a simple gas into an extraordinary material.

Summary Table:

| Process Stage | Key Action | Catalyst Role |

|---|---|---|

| Adsorption & Decomposition | Carbon precursor gas (e.g., CH₄) breaks down on the hot metal surface. | Provides active sites to lower the energy barrier for decomposition. |

| Diffusion & Nucleation | Liberated carbon atoms diffuse and form stable clusters (nucleation sites). | The surface quality dictates nucleation density and crystal size. |

| Crystal Growth & Coalescence | Carbon atoms attach to cluster edges, growing islands that merge into a continuous film. | Enables self-assembly of the hexagonal carbon lattice at practical temperatures (~1000°C). |

Ready to Master Your Graphene Synthesis?

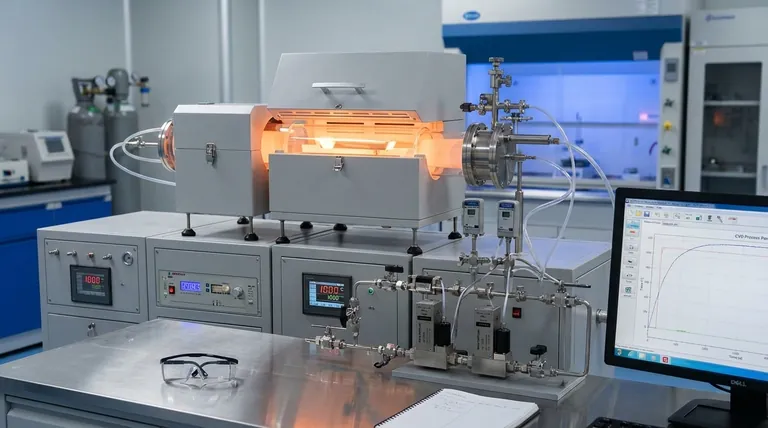

Understanding the mechanism is the first step; achieving consistent, high-quality results is the next. The right equipment is critical for precise control over temperature, pressure, and gas flow—the very parameters that determine your graphene's quality.

KINTEK specializes in high-performance lab equipment and consumables, serving the precise needs of materials science and nanotechnology laboratories. Whether you are scaling up production or pushing the boundaries of fundamental research, our CVD systems and support can help you optimize your process.

Contact us today to discuss how we can support your specific graphene growth goals. Let's build the future of materials, together.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- What is the process of vacuum vapor deposition? Mastering CVD and PVD Thin-Film Coating

- What is the vapor phase deposition technique? A Guide to PVD & CVD Thin-Film Coating Methods

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition