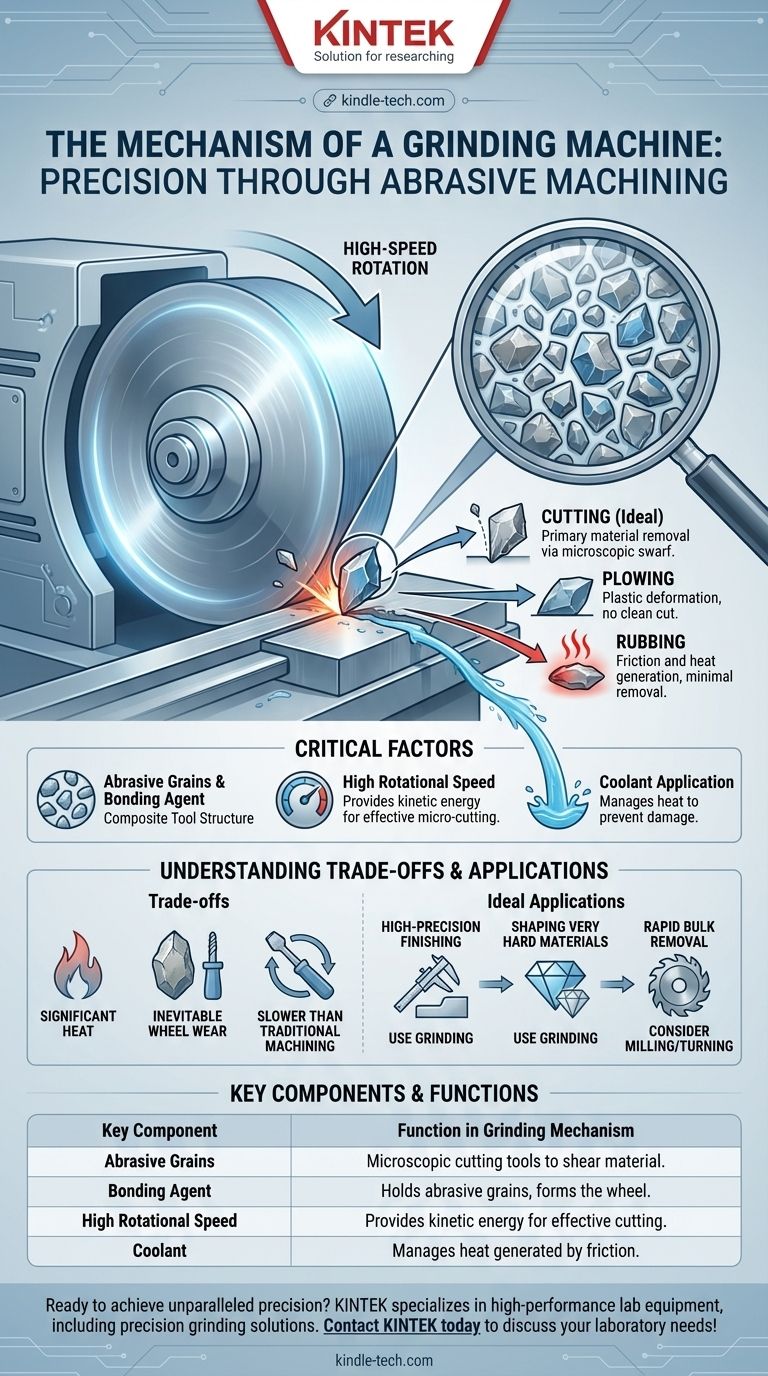

At its core, a grinding machine works by using a high-speed rotating wheel embedded with thousands of microscopic, hard abrasive particles. As this wheel makes contact with a workpiece, each individual abrasive grain acts as a tiny cutting tool, shearing away minuscule chips of material. This collective abrasive action is what shapes, finishes, and refines the surface.

The essential mechanism of a grinding machine is not a single cutting edge, but rather the cumulative effect of countless microscopic cutting points working in unison. This method allows for the removal of material with extremely high precision, making it a finishing process rather than one for bulk removal.

The Core Principle: Abrasive Machining

To truly understand the mechanism, you must think of the grinding wheel not as a solid disc, but as a complex, multi-point cutting tool. The process is a controlled form of abrasion on a microscopic scale.

The Grinding Wheel: A Composite Tool

The grinding wheel itself is made of two primary components: abrasive grains and a bonding agent.

The abrasive grains are extremely hard materials like aluminum oxide or silicon carbide. Each particle has sharp, irregular edges that function as the cutting surfaces. The bonding agent acts like a matrix, holding these grains together and providing the wheel's structure.

The Three Primary Actions at the Surface

When a single abrasive grain on the rotating wheel meets the workpiece, one of three actions occurs. The efficiency of the grinding process depends on the balance between them.

- Cutting: The ideal action. A sharp grain penetrates the workpiece surface and shears off a tiny chip of material, known as swarf. This is the primary method of material removal.

- Plowing: The grain pushes material out of its way without actually creating a separate chip. This plastically deforms the surface rather than removing material cleanly.

- Rubbing: A worn or poorly oriented grain simply slides against the workpiece. This creates significant friction and heat but removes very little material.

The Critical Role of High Speed

The high rotational speed of the grinding wheel is fundamental to the mechanism. This velocity provides the necessary kinetic energy for each tiny grain to make an effective cut.

High speed ensures that even microscopic cutting points can overcome the material's strength, enabling a high rate of material removal when considering the thousands of grains making contact every second.

Understanding the Trade-offs

While powerful, the grinding mechanism has inherent characteristics that you must manage to achieve the desired outcome. Understanding these trade-offs is key to mastering the process.

Significant Heat Generation

The combination of cutting, plowing, and especially rubbing generates immense friction and heat at the point of contact. If not managed with coolant, this heat can burn the workpiece, introduce thermal stress, or alter its metallurgical properties.

Inevitable Wheel Wear

The abrasive grains are not indestructible. They can fracture, dull, and wear down over time. The bonding material also breaks down, causing grains to be pulled out. This wheel wear changes the geometry and cutting effectiveness of the wheel, requiring it to be periodically "dressed" or "trued" to expose fresh, sharp grains.

Slower Than Traditional Machining

Compared to processes like milling or turning that use larger, dedicated cutting tools, grinding is a slower method for removing large volumes of material. Its primary strength lies in its precision and finishing capability, not in rapid, bulk stock removal.

Making the Right Choice for Your Goal

Understanding the mechanism of countless abrasive points allows you to apply the process correctly to achieve your specific manufacturing objective.

- If your primary focus is high-precision finishing: The grinding mechanism is ideal, as the tiny, cumulative cuts allow for exceptional surface smoothness and the ability to hold extremely tight dimensional tolerances.

- If your primary focus is shaping very hard materials: The abrasive action is one of the few methods effective on materials like hardened steel, ceramics, or carbides that are too hard for conventional cutting tools.

- If your primary focus is rapid, bulk material removal: The grinding mechanism is generally inefficient; consider processes like milling or turning for initial roughing stages before a final grinding pass.

By recognizing that grinding is a high-precision system of microscopic cutting, you can leverage its unique capabilities for tasks that demand the highest levels of accuracy and surface quality.

Summary Table:

| Key Component | Function in the Grinding Mechanism |

|---|---|

| Abrasive Grains | Act as countless microscopic cutting tools to shear material. |

| Bonding Agent | Holds the abrasive grains together to form the grinding wheel. |

| High Rotational Speed | Provides kinetic energy for effective cutting by each grain. |

| Coolant | Manages heat generated by friction to prevent workpiece damage. |

Ready to achieve unparalleled precision in your lab? The right grinding equipment is key to leveraging this microscopic cutting mechanism for perfect surface finishes on even the hardest materials. KINTEK specializes in high-performance lab equipment and consumables, including precision grinding solutions. Let our experts help you select the ideal machine for your specific application. Contact KINTEK today to discuss your laboratory needs and enhance your capabilities!

Visual Guide

Related Products

- Liquid Nitrogen Cryogenic Grinder Mill Cryomill Airflow Ultrafine Pulverizer

- Low-Temperature Water-Cooled Touchscreen Vibratory Ultrafine Pulverizer

- Mini Planetary Ball Mill Machine for Laboratory Milling

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- Twin Screw Extruder Plastic Granulation Machine

People Also Ask

- What is the process of cryogenic ball milling? Achieve Superior Nanomaterial Synthesis

- What is cryogenic machining used for? Process Unmachinable Materials with Extreme Cold

- Why is a cryogenic grinder required for cured alkyd resin HRMAS NMR? Ensure Structural Integrity & Sample Precision

- What is the mechanism of a cryogenic grinder? Master Polymer Powder Preparation for Additive Manufacturing

- What is the role of a cryogenic grinder in PET recycling? Transform Waste into High-Reactive Micron Powders