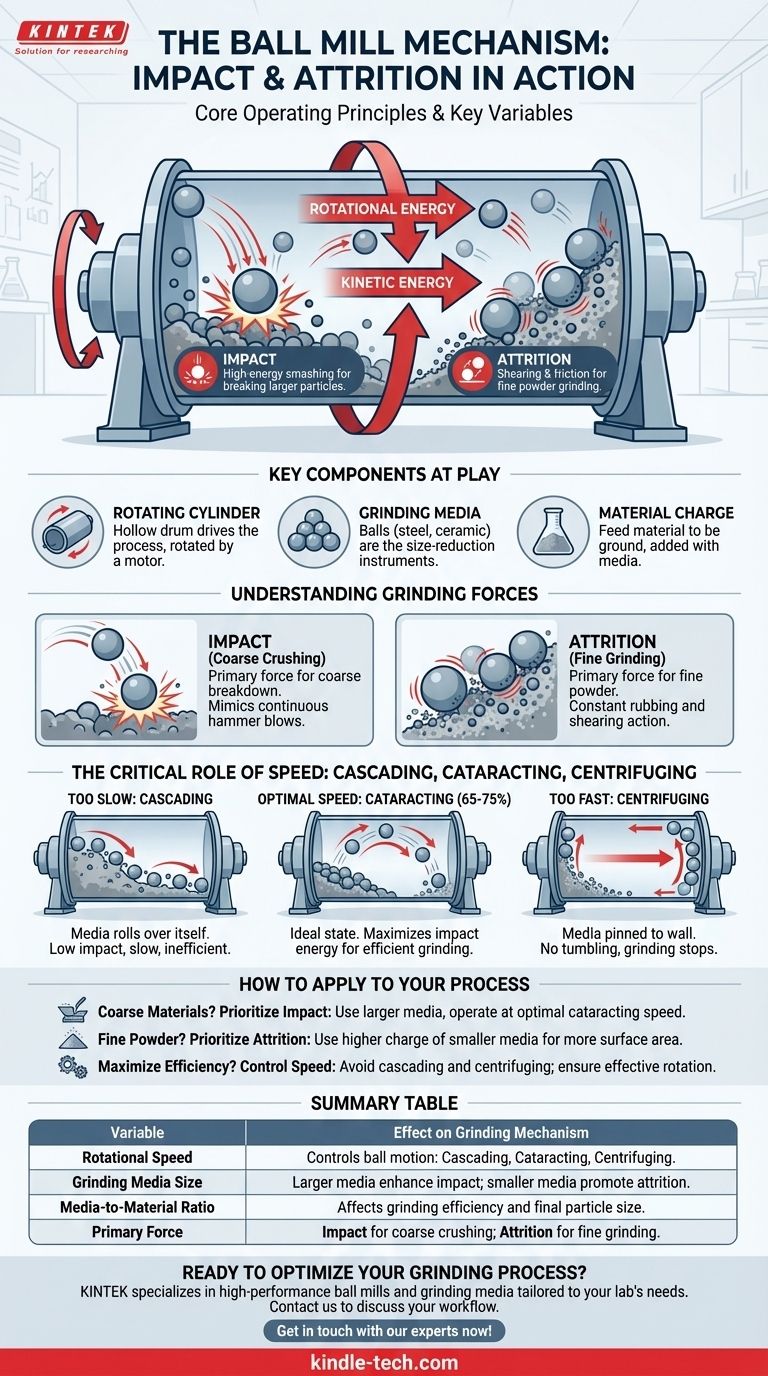

At its core, a ball mill operates on the dual principles of impact and attrition. A rotating horizontal cylinder tumbles grinding media (balls) and the material to be ground. The balls are lifted by the rotation and then fall, creating a high-energy impact that smashes the material. Simultaneously, the sliding and rolling of the balls against each other and the cylinder wall creates an attrition force that shears and grinds the material into a fine powder.

The essential mechanism isn't just the presence of balls in a drum; it's the controlled transformation of rotational energy into kinetic energy. The mill's rotational speed is the critical variable that dictates whether the grinding media will effectively crush and grind the material or fail to do so.

The Key Components at Play

To understand the mechanism, we must first look at the three primary components involved in the process. Each plays a distinct and necessary role.

The Rotating Cylinder

This is the main body of the mill, a hollow drum that is typically mounted horizontally. It is rotated on its longitudinal axis by a powerful motor, providing the energy that drives the entire grinding process.

The Grinding Media

These are the balls (or sometimes rods) placed inside the cylinder. They are the instruments of size reduction. Media can be made from materials like high-carbon steel, stainless steel, or ceramic, chosen based on the material being ground and the need to avoid contamination.

The Material Charge

This is the feed material that needs to be ground. It is added to the cylinder along with the grinding media. The ratio of grinding media to material charge is a key parameter in optimizing the mill's performance.

The Two Grinding Forces: Impact and Attrition

The entire purpose of the ball mill is to orchestrate a collision of forces. The combination of two distinct actions ensures efficient size reduction for a wide range of materials.

Understanding Impact

Impact is the primary force for breaking down larger, coarser particles. As the cylinder rotates, it lifts the grinding media up the side of the drum. At a certain point, gravity overcomes the forces holding the balls to the wall, and they drop, crashing down onto the material at the bottom of the mill. This action is like thousands of tiny hammer blows happening continuously.

Understanding Attrition

Attrition is a shearing and friction force, most effective at grinding smaller particles into a fine powder. This occurs as the balls tumble and slide against one another and the inner wall of the cylinder, with the material trapped between them. This constant rubbing wears the particles down.

Understanding the Trade-offs: The Critical Role of Speed

The effectiveness of a ball mill is almost entirely dependent on its rotational speed. An incorrect speed will render the process inefficient or completely ineffective.

Too Slow: The Cascading Effect

If the mill rotates too slowly, the grinding media will simply be picked up a short distance before tumbling back down the surface of the other balls. This is known as cascading. While it generates some attrition, there is very little impact force, making the process extremely slow and inefficient for breaking down coarse material.

Too Fast: The Centrifuging Effect

If the mill rotates too fast, it reaches a "critical speed" where centrifugal force overcomes gravity. The grinding media and material charge are simply pinned against the inside of the cylinder wall. They rotate with the drum as a solid mass, and no tumbling or impact occurs. Grinding stops completely.

The Optimal Speed: The Cataracting Effect

The ideal state is cataracting, which typically occurs at around 65-75% of the critical speed. Here, the balls are carried high up the side of the cylinder and then fall in a free-falling arc, maximizing the impact energy upon the material charge at the bottom. This ensures a healthy balance of both powerful impact and continuous attrition.

How to Apply This to Your Process

You can manipulate the final particle size and efficiency of your operation by controlling several key variables based on these mechanical principles.

- If your primary focus is breaking down coarse, hard materials: Prioritize impact force by using larger, heavier grinding media and ensuring the mill operates at the optimal "cataracting" speed to maximize drop height.

- If your primary focus is producing a very fine, uniform powder: Use a higher charge of smaller grinding media to increase surface area and promote the attrition force, which is more effective for fine grinding.

- If your primary focus is maximizing efficiency and throughput: Carefully control the rotational speed to avoid both cascading and centrifuging, ensuring every rotation contributes effectively to size reduction.

By understanding these mechanical principles, you can transform the ball mill from a simple grinder into a precision tool for material processing.

Summary Table:

| Variable | Effect on Grinding Mechanism |

|---|---|

| Rotational Speed | Controls ball motion: Cascading (slow), Cataracting (optimal), Centrifuging (fast). |

| Grinding Media Size | Larger media enhance impact; smaller media promote attrition for fine powders. |

| Media-to-Material Ratio | Affects grinding efficiency and final particle size distribution. |

| Primary Force | Impact for coarse crushing; Attrition for fine grinding. |

Ready to Optimize Your Grinding Process?

Understanding the core mechanism of impact and attrition is the first step. Achieving precise particle size control and maximum efficiency requires the right equipment and expert support.

KINTEK specializes in high-performance ball mills and grinding media tailored to your laboratory's specific needs. Whether you're processing hard, coarse materials or aiming for a ultra-fine powder, we provide solutions that transform rotational energy into consistent, reliable results.

Contact us today to discuss how our expertise in lab equipment can enhance your material processing workflow. Let's find the perfect grinding solution for you.

Get in touch with our experts now!

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What are the disadvantages of a ball mill? High Energy Use, Noise, and Contamination Risks

- Why use ball milling for NMC cathode materials? Achieve Precision Particle Sizing for Composite Cathodes

- What is the key role of a planetary ball mill for IZO targets? Achieve Atomic-Level Uniformity in Material Preparation

- What is the difference between a ball mill and a sag mill? A Guide to Primary vs. Secondary Grinding

- What role does a planetary ball mill play in eggshell fertilizer production? Unlock Superior Chemical Reactivity