By far, the most common metal used for blacksmithing is low-carbon steel, commonly known as "mild steel." It is the default material for beginners and a staple for professionals due to its unique combination of low cost, wide availability, and forgiving workability. For anyone learning the craft, starting with mild steel is the standard and most effective path.

The core principle is this: master the fundamental skills on a forgiving material before introducing complexity. Mild steel's tolerance for error allows you to focus on learning heat control, hammer technique, and shaping without the added challenge and expense of specialized alloys.

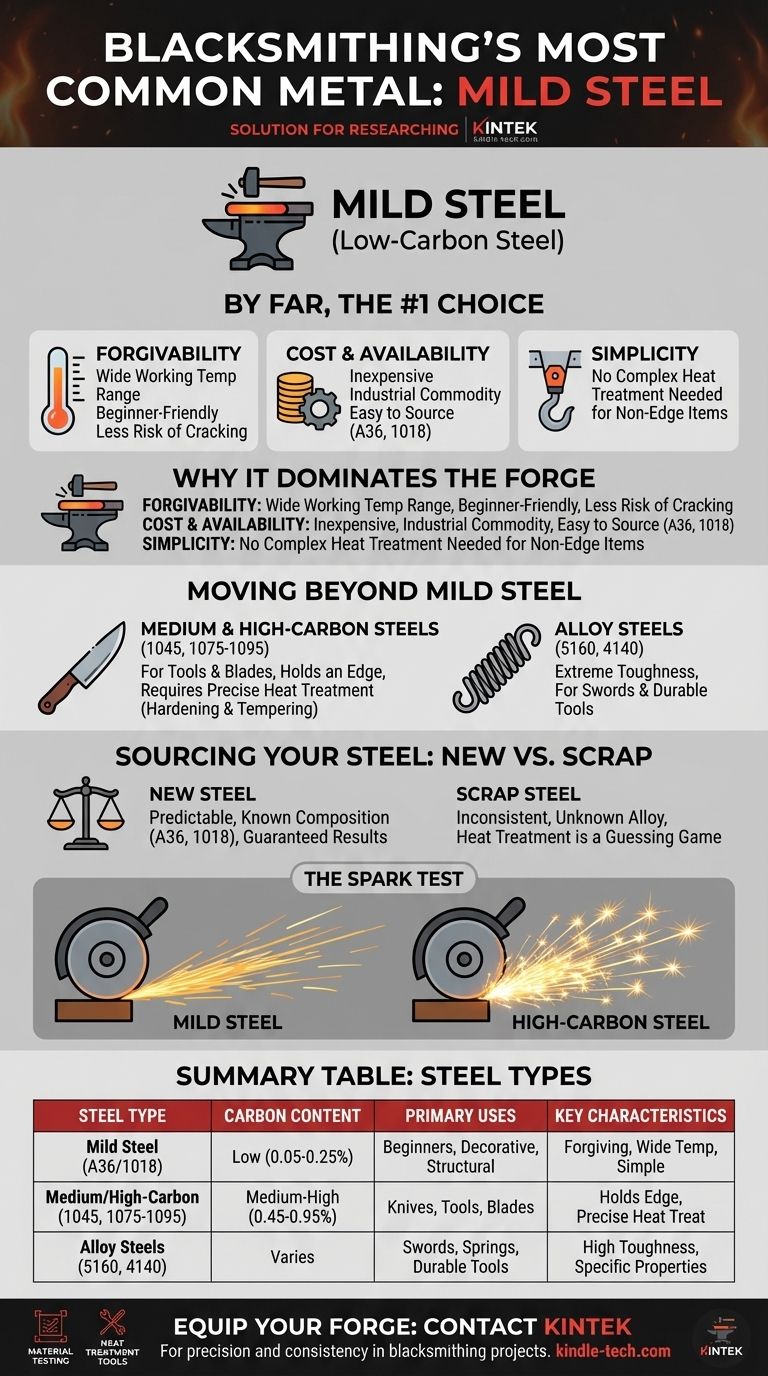

Why Mild Steel Dominates the Forge

The near-universal recommendation for mild steel isn't based on tradition alone; it's rooted in its fundamental properties, which are perfectly suited for the learning process and a wide range of general-purpose work.

The Critical Factor: Forgivability

Mild steel has a very wide working temperature range. This means it can be effectively shaped from a bright orange to a yellow heat without a high risk of cracking or crumbling.

For a beginner who is still developing an eye for temperature, this is a crucial safety net. Overheating or underheating the metal slightly won't instantly ruin your workpiece, unlike more sensitive high-carbon steels.

Unbeatable Economics: Cost and Availability

Blacksmithing consumes a significant amount of material, especially during practice. Mild steel is an industrial commodity, making it the cheapest and most accessible form of steel you can buy.

You can purchase it easily from local steel suppliers in standard shapes like round bar, square bar, and flat stock, ensuring you always have a consistent and predictable material to work with.

Simplicity in Practice: No Complex Heat Treatment

For items that don't need to hold a sharp edge, like hooks, brackets, railings, or decorative pieces, mild steel is strong enough right out of the forge.

It does not require the complex, multi-step process of hardening and tempering that is mandatory for high-carbon steels. This simplifies the process immensely, allowing you to focus on the art of shaping the metal.

Moving Beyond Mild Steel: The Carbon Spectrum

While mild steel is the workhorse, different projects demand different materials. The key differentiator between most steels used in blacksmithing is their carbon content. More carbon allows steel to become significantly harder, but it also makes it less forgiving to forge.

Medium & High-Carbon Steels: For Tools and Blades

Steels like 1045 (medium-carbon) and the series from 1075 to 1095 (high-carbon) are used when you need the final object to hold an edge or withstand high impact and wear. This includes knives, axes, chisels, and hammers.

Forging these steels requires more precise temperature control. Critically, after forging, they must be heat-treated (heated to a critical temperature and quenched in oil or water) and then tempered (re-heated to a lower temperature) to achieve the desired balance of hardness and toughness.

Alloy Steels: Engineered for Performance

Alloy steels, such as 5160 (spring steel) or 4140 (chrome-moly steel), contain other elements besides iron and carbon. These elements impart specific qualities like extreme toughness, flexibility, and abrasion resistance.

They are used for high-performance applications like swords, vehicle leaf springs, and durable smithing tools like tongs and hammers. Each alloy has its own unique forging and heat-treatment requirements.

Understanding the Trade-offs: Sourcing Your Material

Where you get your steel is as important as what type of steel you get. The choice is primarily between new, known steel and recycled "mystery" steel.

The Case for New Steel: Predictability is Key

Buying new steel from a reputable supplier (e.g., A36 or 1018 mild steel) guarantees you know its exact composition. This predictability is essential when learning. All your results—good or bad—come from your technique, not from an unknown variable in the material itself.

The Allure and Danger of "Junkyard" Steel

Scrap yards can be a tempting source of free or cheap material, like rebar, leaf springs, coil springs, and old tools. This can be a great way to get practice material.

However, the major drawback is that you rarely know the exact alloy. A leaf spring is probably 5160 steel, but it could be something else. Rebar is a form of mild steel, but its quality and composition can be notoriously inconsistent. Forging unknown steel makes heat treatment a guessing game.

A Practical Guide to Identifying Mystery Metal

The spark test is a classic blacksmithing method for getting a rough idea of a steel's carbon content. By touching the metal to a grinder, you can observe the spark pattern.

- Mild Steel: Long, yellowish-orange sparks that flow in straight lines with very few forks or bursts.

- High-Carbon Steel: A much denser, brighter, and shorter spark stream that explodes into many complex, star-like bursts close to the grinder.

Selecting the Right Steel for Your Goal

Your project's purpose dictates your material choice. Use this as your guide.

- If you are a complete beginner: Start with new, known mild steel (like A36 or 1018) to master the fundamentals of hammering and heat control without interference from the material.

- If you are making decorative or structural items (hooks, gates, brackets): Mild steel is your most efficient and cost-effective choice.

- If you want to forge a knife or a tool that holds an edge: Use a known high-carbon steel like 1084 or 5160 and be prepared to learn the precise science of heat treatment.

- If you are practicing on a tight budget: Use scrap steel for shaping practice, but avoid using it for tools or blades until you can confidently identify and test it.

Choosing the correct material is the foundational decision that sets the stage for a successful project in the forge.

Summary Table:

| Steel Type | Carbon Content | Primary Uses | Key Characteristics |

|---|---|---|---|

| Mild Steel (A36/1018) | Low (0.05-0.25%) | Beginners, decorative work, structural items | Forgiving, wide working temp, no complex heat treatment needed |

| Medium/High-Carbon (1045, 1075-1095) | Medium to High (0.45-0.95%) | Knives, tools, blades | Holds an edge, requires precise heat treatment |

| Alloy Steels (5160, 4140) | Varies with alloying elements | Swords, springs, durable tools | High toughness, specific performance properties |

Ready to equip your forge with the right materials? Whether you're a beginner mastering the basics with mild steel or an experienced smith working with high-carbon alloys, having reliable equipment is key to success. KINTEK specializes in lab and workshop equipment, including tools for material testing and heat treatment processes. Let us help you achieve precision and consistency in your blacksmithing projects. Contact our experts today to discuss your specific needs!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- Is pyrolysis oil harmful? Understanding the Risks of This Reactive Biofuel

- What are the techniques of sintering? Choose the Right Method for Your Material

- How thick is sputter coating? Achieve Precision Thin Films from Nanometers to Microns

- What does HIP process do? Eliminate Porosity for Superior Material Performance

- What is the use of sinter in blast furnace? Optimize Iron Production with Engineered Feedstock

- Can filter paper be used to separate solids from liquids? A Guide to Effective Filtration

- What is the physical Vapour deposition method? A Guide to High-Performance Thin Films

- Why is magnetron sputtering used? For High-Quality, High-Purity Thin Film Deposition