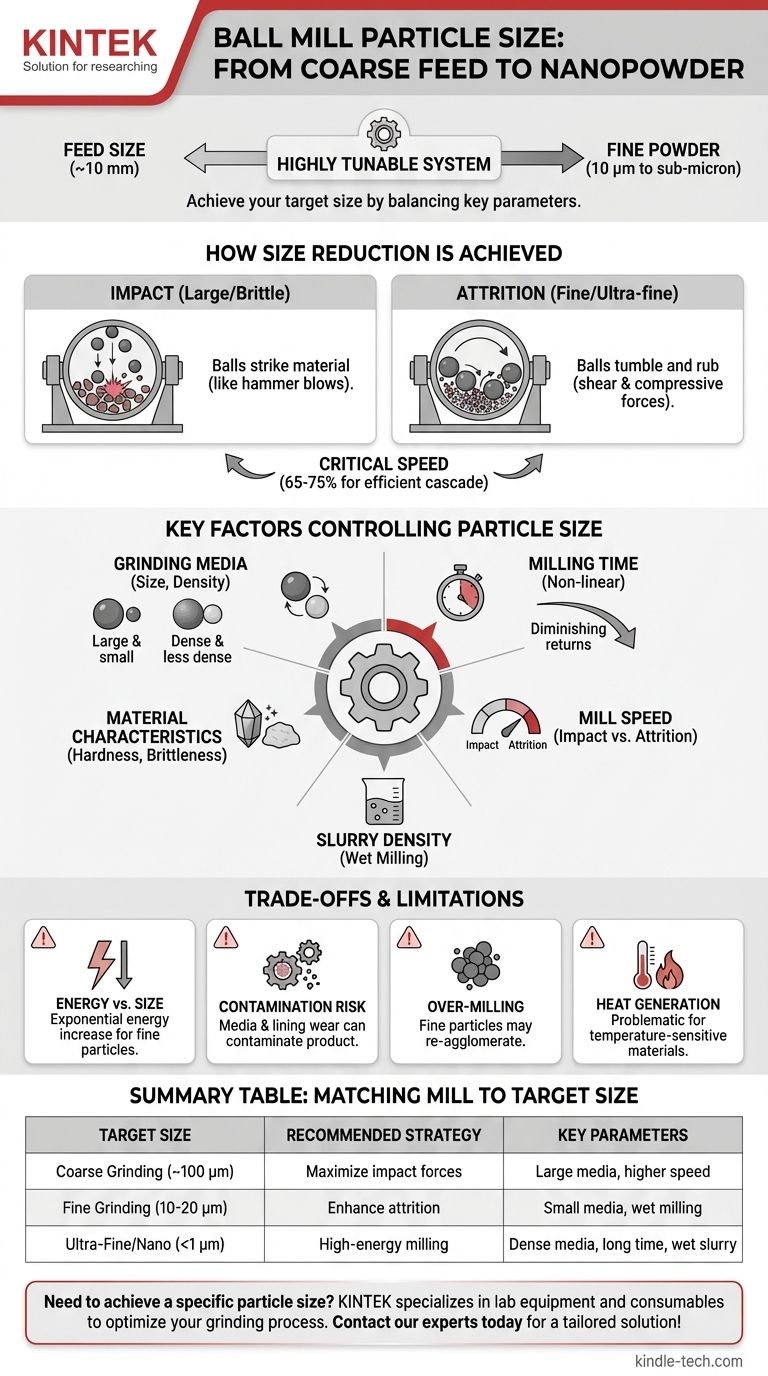

In short, a ball mill is a highly versatile tool capable of grinding materials from a feed size of around 10 mm down to an exceptionally fine powder, often reaching 10 microns or even into the sub-micron (nanoparticle) range. However, this wide range is not automatic; the final particle size is a direct result of carefully controlling the milling parameters.

The key takeaway is that a ball mill does not have one fixed particle size range. Instead, it is a highly tunable system where the final particle size is determined by a balance of factors, including the grinding media, mill speed, milling time, and the properties of the material itself.

How a Ball Mill Achieves Size Reduction

A ball mill reduces particle size through a combination of two primary mechanisms: impact and attrition. Understanding how these forces work is the first step to controlling the final output.

The Role of Impact

Impact occurs when the grinding media (the balls) are lifted high up the side of the rotating drum and then fall, striking the material. This action is like a multitude of tiny hammer blows, effective at breaking down larger, brittle particles.

The Role of Attrition

Attrition is the grinding action that occurs as the balls tumble over each other. This creates shear and compressive forces that rub particles apart, which is essential for achieving very fine and ultra-fine powders.

The Concept of Critical Speed

The speed of the mill's rotation dictates which mechanism dominates. Critical speed is the theoretical speed at which the balls would simply centrifuge and stick to the mill wall, ceasing all grinding. Mills are typically operated at 65-75% of critical speed to create a cascading motion that balances both impact and attrition for efficient grinding.

Key Factors Controlling Final Particle Size

Achieving your target particle size is not a matter of chance. It is the result of precisely managing several interconnected variables.

Grinding Media (The Balls)

The size, density, and material of the grinding media are arguably the most critical factors.

- Size: Larger balls create greater impact forces, ideal for breaking down coarse feed. Smaller balls provide a much larger surface area, which enhances attrition for fine grinding.

- Density: Denser media (like tungsten carbide or zirconia) transfer more energy per impact than less dense media (like alumina or steel), leading to more efficient grinding.

Milling Time

Generally, the longer you run the mill, the finer the resulting particles will be. However, this relationship is not linear. The rate of size reduction slows significantly as particles get smaller, and excessive milling time can lead to problems.

Mill Speed

Operating closer to the critical speed (e.g., 75-80%) favors impact forces, which is useful for initial coarse grinding. A slower speed (e.g., 60-65%) promotes a cascading action, increasing the time for attrition and producing a finer grind.

Material Characteristics

The inherent properties of the material you are milling have a profound effect. A hard, brittle material like quartz will grind very differently from a softer, more ductile material.

Charge Volume and Slurry Density

For wet milling, the ratio of solids, liquid, and grinding media is crucial. A slurry that is too thick will cushion the impacts, reducing efficiency. A slurry that is too thin will not provide enough particles between the media for effective grinding.

Understanding the Trade-offs and Limitations

While powerful, a ball mill is not without its operational constraints. Understanding these is essential for process optimization and quality control.

Energy vs. Particle Size

Reducing particle size is an energy-intensive process. It requires exponentially more energy and time to break a 10-micron particle into a 1-micron particle than it does to break a 100-micron particle into a 10-micron particle.

Contamination Risk

The constant tumbling and impact causes wear on both the grinding media and the mill's inner lining. This worn material can contaminate your final product, a critical consideration for high-purity applications like pharmaceuticals or advanced ceramics.

Over-Milling and Agglomeration

Milling for too long can be counterproductive. Extremely fine particles can develop high surface energy and begin to re-agglomerate, effectively increasing the particle size. This is particularly common in dry milling.

Heat Generation

The mechanical energy of milling generates significant heat. This can be problematic for temperature-sensitive materials, potentially causing degradation or phase changes. For this reason, water-jacketed mills are often used for such applications.

Matching the Mill to Your Target Size

Your operational strategy should be dictated entirely by your desired outcome.

- If your primary focus is coarse grinding (e.g., reducing 5 mm feed to ~100 microns): Use larger grinding media to maximize impact forces and operate at a slightly higher percentage of critical speed.

- If your primary focus is fine grinding (e.g., taking 100-micron feed down to 10-20 microns): Use smaller grinding media to increase surface area and attrition, and consider wet milling to prevent agglomeration.

- If your primary focus is ultra-fine or nanoparticle production (< 1 micron): You will likely need specialized high-energy equipment (like a planetary or stirred media mill), very small and dense media (e.g., yttria-stabilized zirconia), and long processing times in a wet, well-dispersed slurry.

By understanding these core principles, you can transform the ball mill from a simple grinder into a precise particle engineering tool.

Summary Table:

| Target Particle Size | Recommended Strategy | Key Parameters |

|---|---|---|

| Coarse Grinding (~100 microns) | Maximize impact forces | Large media, higher speed |

| Fine Grinding (10-20 microns) | Enhance attrition | Small media, wet milling |

| Ultra-Fine/Nano (<1 micron) | High-energy milling | Dense media, long time, wet slurry |

Need to achieve a specific particle size for your materials? KINTEK specializes in lab equipment and consumables, providing the right ball mills and expert guidance to optimize your grinding process for superior results. Contact our experts today to discuss your application and get a tailored solution!

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What is the primary function of mechanical grinding equipment in the physical modification of lignin?

- Why is high-speed stirring equipment necessary in carbon nanotube adsorption experiments? Optimize Your Lab Results

- What are the elements of a ball mill? A Guide to Its Core Components and Grinding Efficiency

- What are the parameters of the ball mill process? Optimize Grinding for Efficiency and Particle Size

- What technical problem does a micronizing mill solve for LSTH solid electrolytes? Enhance Sintering & Density

- How does ultrasonic dispersion equipment assist in substrate pretreatment? Master Diamond Thin Film Nucleation

- Which method of grinding is most effective for small samples? Maximize Yield and Integrity for Precious Materials

- What is the function of a ball mill in Reaction Bonded Boron Carbide? Achieve Optimal Powder Homogeneity for RBBC