In Plasma-Enhanced Chemical Vapor Deposition (PECVD), plasma is generated by applying a strong electrical field to a reactive gas inside a low-pressure chamber. This field energizes the gas, stripping electrons from its atoms and molecules to create a highly reactive mixture of ions, electrons, and neutral radicals known as a glow discharge.

The fundamental purpose of generating plasma in PECVD is to create the necessary chemical reactivity for film deposition without relying on high heat. This allows for the coating of temperature-sensitive materials that would be damaged by traditional thermal processes.

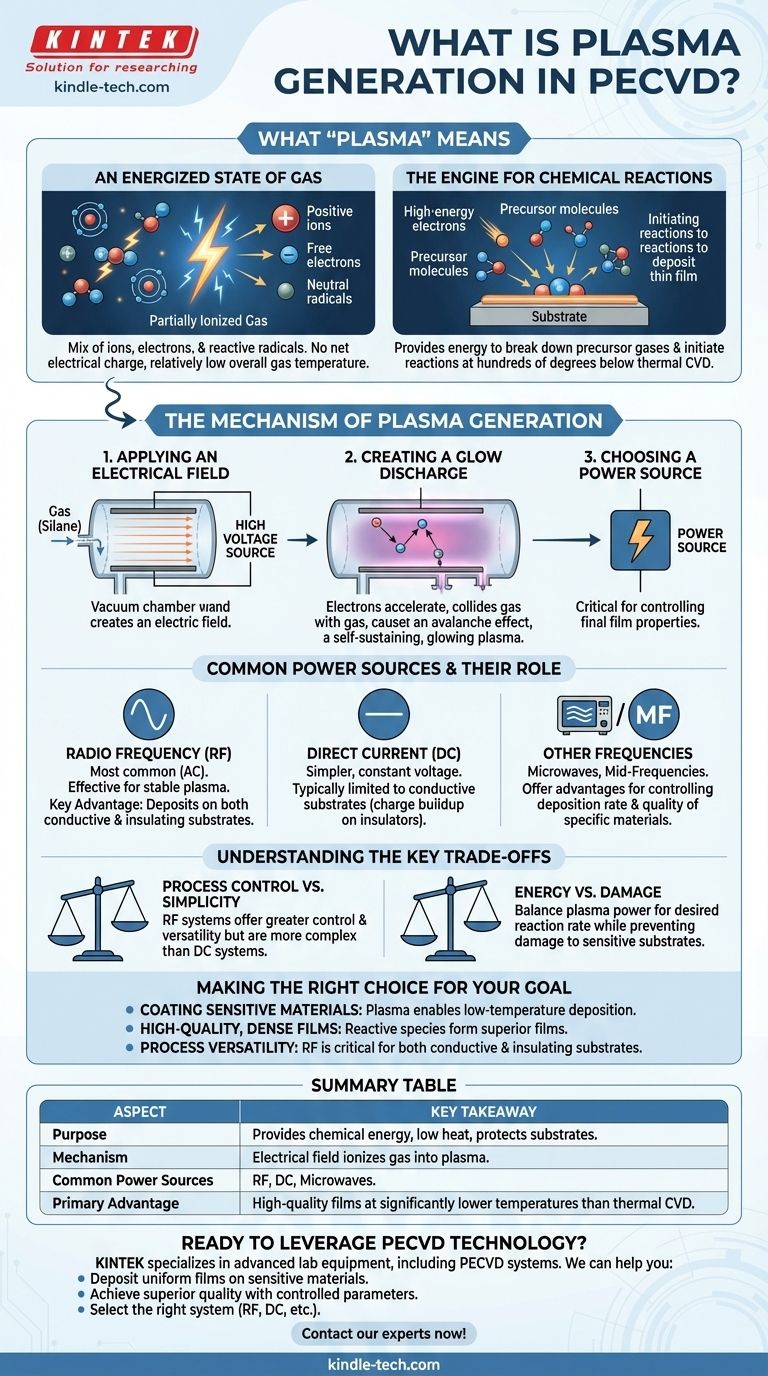

What "Plasma" Means in This Context

An Energized State of Gas

Plasma is often called the fourth state of matter. In PECVD, it refers to a partially ionized gas containing a mix of positively charged ions, free electrons, and highly reactive, electrically neutral fragments of molecules called radicals.

While the plasma contains extremely high-energy particles, it has no net electrical charge and the overall temperature of the gas can remain relatively low.

The Engine for Chemical Reactions

The high-energy electrons and radicals within the plasma are the true workhorses of the process. They provide the energy needed to break down the precursor gases and initiate the chemical reactions that lead to the desired thin film depositing on the substrate surface.

This energy transfer is far more efficient than simple thermal heating, enabling reactions to occur at hundreds of degrees below what conventional Chemical Vapor Deposition (CVD) would require.

The Mechanism of Plasma Generation

Step 1: Applying an Electrical Field

The process begins by introducing a precursor gas (like silane) into a vacuum chamber. Two electrodes within the chamber are then subjected to a high voltage.

This creates a powerful electrical field in the space between the electrodes, where the gas resides.

Step 2: Creating a Glow Discharge

The electrical field accelerates the few free electrons naturally present in the gas. As these high-speed electrons collide with gas molecules, they knock off more electrons.

This creates a chain reaction, or avalanche, that rapidly ionizes the gas. The result is a self-sustaining, glowing discharge—the plasma—which fills the reaction chamber.

Step 3: Choosing a Power Source

This electrical field is not static; it is powered by a specific source designed to sustain the plasma effectively.

The choice of power source is a critical parameter in controlling the properties of the final film.

Common Power Sources and Their Role

Radio Frequency (RF)

RF power, which is a form of alternating current (AC), is the most common method for plasma generation in PECVD. The rapidly alternating field is highly effective at energizing electrons and can sustain a stable plasma.

Its key advantage is the ability to deposit films on both electrically conductive and insulating substrates.

Direct Current (DC)

A DC power source applies a constant voltage between the electrodes. This method is simpler and often used for depositing conductive films.

However, its use is typically limited to conductive substrates because a charge buildup on an insulating surface would quickly neutralize the electric field and extinguish the plasma.

Other Frequencies

Systems may also use microwaves or mid-frequencies (MF) to energize the gas. Each frequency range interacts with the gas differently, offering specific advantages for controlling the deposition rate and quality of certain materials.

Understanding the Key Trade-offs

Process Control vs. Simplicity

While the concept is straightforward, creating a uniform and stable plasma is a significant engineering challenge. RF systems are more complex than DC systems but offer far greater process control and material versatility.

Energy vs. Damage

The high-energy ions in the plasma that enable low-temperature deposition can also cause damage to the substrate surface or the growing film.

Engineers must carefully balance the plasma power to ensure it is high enough for the desired reaction rate but low enough to prevent plasma-induced damage to sensitive devices.

Making the Right Choice for Your Goal

The method of plasma generation directly impacts the capabilities of the deposition process. Your primary objective will determine the most suitable approach.

- If your primary focus is coating temperature-sensitive materials (like plastics): The key insight is that plasma provides the reaction energy, making low-temperature deposition possible.

- If your primary focus is creating high-quality, dense films: Plasma generates highly reactive chemical species that enable the formation of superior films compared to thermal methods at the same low temperatures.

- If your primary focus is process versatility on any material: An RF-based system is critical, as it allows for uniform deposition on both conductive and insulating substrates.

Ultimately, plasma generation is the core technology that transforms conventional CVD into a powerful and versatile tool for modern materials engineering.

Summary Table:

| Aspect | Key Takeaway |

|---|---|

| Purpose | Provides chemical energy for deposition without high heat, protecting temperature-sensitive substrates. |

| Mechanism | An electrical field ionizes gas, creating a reactive plasma of ions, electrons, and radicals. |

| Common Power Sources | Radio Frequency (RF), Direct Current (DC), Microwaves. |

| Primary Advantage | Enables high-quality film deposition at temperatures hundreds of degrees lower than thermal CVD. |

Ready to leverage PECVD technology for your advanced materials?

The precise control of plasma generation is key to depositing high-performance thin films on sensitive substrates. KINTEK specializes in advanced lab equipment, including PECVD systems, to meet the exacting needs of materials science and engineering laboratories.

We can help you:

- Deposit uniform films on plastics, semiconductors, and other sensitive materials.

- Achieve superior film quality with controlled plasma parameters.

- Select the right PECVD system (RF, DC, or other) for your specific substrate and application goals.

Contact us today to discuss how our expertise and solutions can accelerate your research and development. #Contact our experts now!

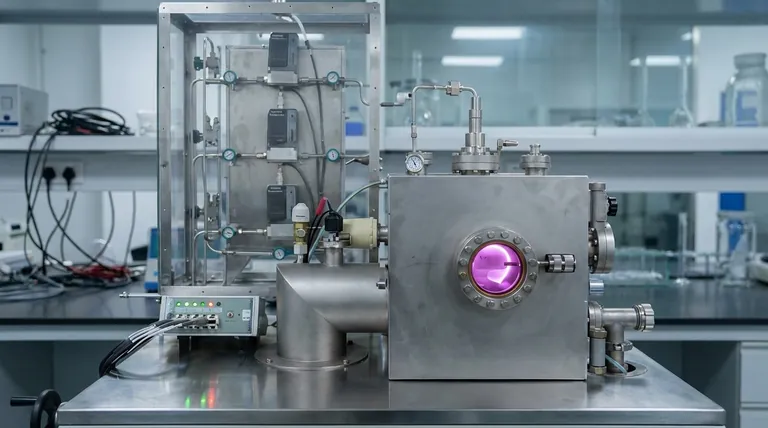

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- Why is a Matching Network Indispensable in RF-PECVD for Siloxane Films? Ensure Stable Plasma and Uniform Deposition

- What are different types of thin films? A Guide to Function, Material, and Deposition Methods

- Why does a PECVD vacuum system require both a rotary vane and turbo pump? Ensure High-Purity Coatings

- What is the process of PECVD in semiconductor? Enabling Low-Temperature Thin Film Deposition

- How do PECVD systems improve DLC coatings on implants? Superior Durability and Biocompatibility Explained