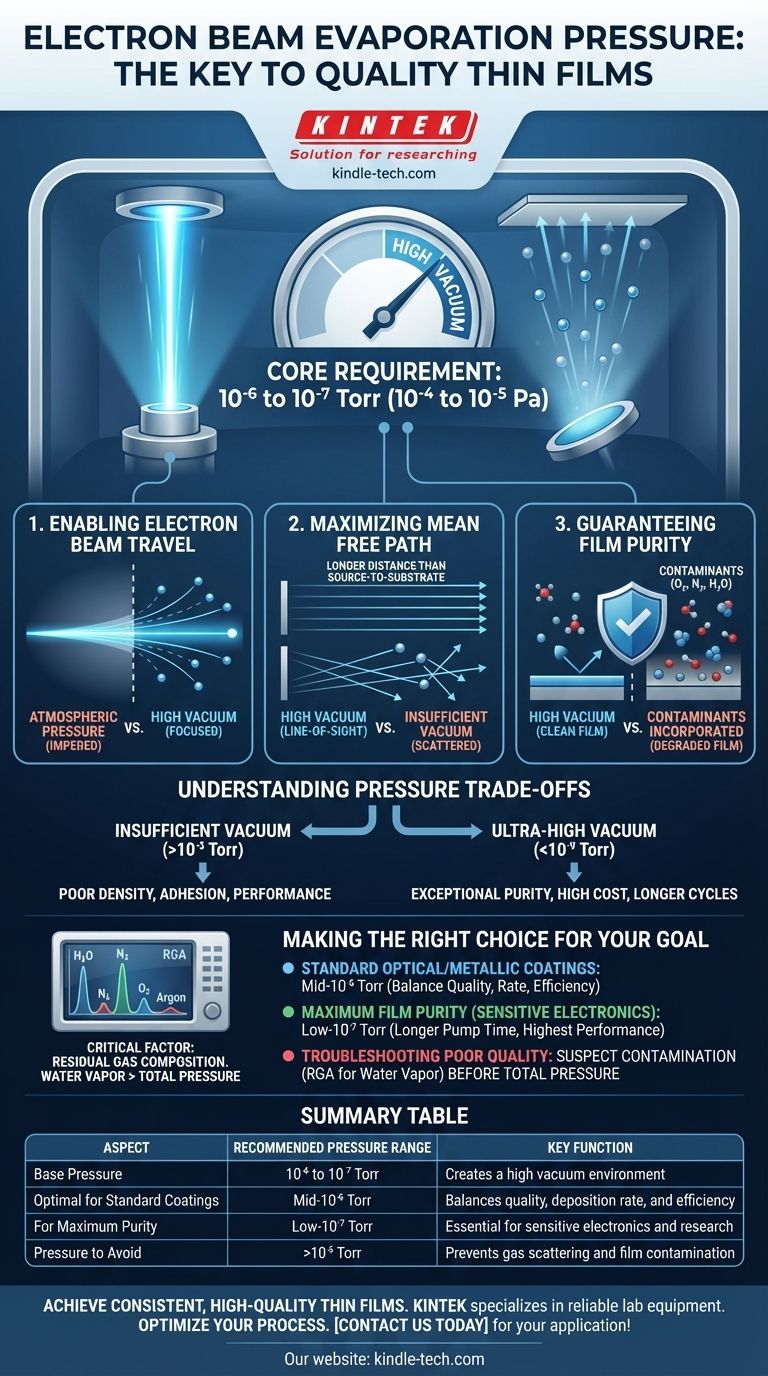

To be effective, electron beam evaporation must be conducted under high vacuum conditions. The process chamber is typically pumped down to a base pressure in the range of 10⁻⁶ to 10⁻⁷ Torr (or approximately 10⁻⁴ to 10⁻⁵ Pascals) before the deposition process begins. This low-pressure environment is fundamental to the success of the technique.

The need for a high vacuum is not arbitrary; it is a prerequisite for both generating the electron beam and ensuring the evaporated material can travel to the substrate to form a pure, dense thin film.

Why High Vacuum is Non-Negotiable

Operating at atmospheric or even low vacuum pressures would make electron beam evaporation impossible. The high vacuum environment serves three critical functions that directly impact the quality of the final coating.

Enabling Electron Beam Travel

The process uses a high-energy beam of electrons, accelerated by voltages up to 10 kV, to heat the source material.

If the chamber contained a significant number of gas molecules, these electrons would collide with them and scatter. This would prevent the beam from remaining focused and delivering its energy efficiently to the target material.

Maximizing the Mean Free Path

Mean free path is the average distance a particle, in this case, an evaporated atom, can travel before it collides with another particle.

In a high vacuum, the mean free path is very long—often much longer than the distance from the source material to the substrate. This ensures the vaporized atoms travel in a straight, "line-of-sight" path and deposit directly onto the substrate.

Guaranteeing Film Purity

The primary goal of e-beam evaporation is to create a high-purity, dense film. Residual gas molecules in the chamber—like oxygen, nitrogen, and especially water vapor—are contaminants.

If these molecules are present during deposition, they will inevitably be incorporated into the growing film. This contamination can severely degrade the film's optical, electrical, and mechanical properties. A high vacuum physically removes these potential contaminants.

Understanding the Pressure Trade-offs

While "high vacuum" is the rule, the specific pressure level involves balancing quality against practical limitations. Simply achieving the lowest possible pressure is not always the most efficient or necessary approach.

The Problem with Insufficient Vacuum

Operating at a pressure higher than the optimal range (e.g., in the 10⁻⁵ Torr range) leads to several problems. The shorter mean free path causes gas scattering, resulting in films that are less dense and more porous.

Furthermore, the higher concentration of residual gases leads directly to a contaminated, lower-quality film with poor performance and adhesion.

The Challenge of Ultra-High Vacuum (UHV)

Pushing into the ultra-high vacuum (UHV) range (10⁻⁹ Torr and below) can produce films of exceptional purity. This is critical for highly sensitive research applications and certain semiconductor devices.

However, achieving UHV requires more complex and expensive pumping systems, specialized chamber materials, and significantly longer pump-down times. For most industrial and optical coatings, the marginal benefit in purity does not justify the immense increase in cost and cycle time.

It's Not Just Total Pressure

Expert practitioners know that the composition of the residual gas is often more important than the total pressure reading. A chamber at 5x10⁻⁶ Torr with mostly inert argon is far better than a chamber at 2x10⁻⁶ Torr that is dominated by water vapor.

Using a Residual Gas Analyzer (RGA) to monitor the partial pressures of specific contaminants provides a much clearer picture of the deposition environment than a simple pressure gauge.

Making the Right Choice for Your Goal

The ideal base pressure is determined by the requirements of your final film. Use these guidelines to set your target.

- If your primary focus is standard optical or metallic coatings: A base pressure in the mid-10⁻⁶ Torr range provides the best balance of high film quality, reasonable deposition rates, and efficient cycle times.

- If your primary focus is maximum film purity for sensitive electronics: Target the low 10⁻⁷ Torr range and consider longer pump times to reduce water vapor. This ensures the highest possible film performance.

- If you are troubleshooting poor film quality: Suspect contamination before blaming total pressure. A high partial pressure of water is a common culprit for issues like poor adhesion and hazy films.

Ultimately, controlling the vacuum environment is the key to mastering the quality and repeatability of your thin-film depositions.

Summary Table:

| Aspect | Recommended Pressure Range | Key Function |

|---|---|---|

| Base Pressure | 10⁻⁶ to 10⁻⁷ Torr | Creates a high vacuum environment for the process |

| Optimal for Standard Coatings | Mid-10⁻⁶ Torr | Balances quality, deposition rate, and efficiency |

| For Maximum Purity | Low-10⁻⁷ Torr | Essential for sensitive electronics and research |

| Pressure to Avoid | >10⁻⁵ Torr | Prevents gas scattering and film contamination |

Achieve consistent, high-quality thin films with the right equipment. The precise vacuum environment is critical for successful electron beam evaporation. KINTEK specializes in providing reliable lab equipment and consumables tailored to your laboratory's deposition needs. Let our experts help you optimize your process for superior results. Contact us today to discuss your specific application and requirements!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Electron Beam Evaporation Coating Conductive Boron Nitride Crucible BN Crucible

- E Beam Crucibles Electron Gun Beam Crucible for Evaporation

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What is the difference between PECVD and sputter? Choose the Right Thin-Film Deposition Method

- What is plasma enhanced? A Guide to Low-Temperature, High-Precision Manufacturing

- What are the components of PECVD? A Guide to Low-Temperature Thin Film Deposition Systems

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications