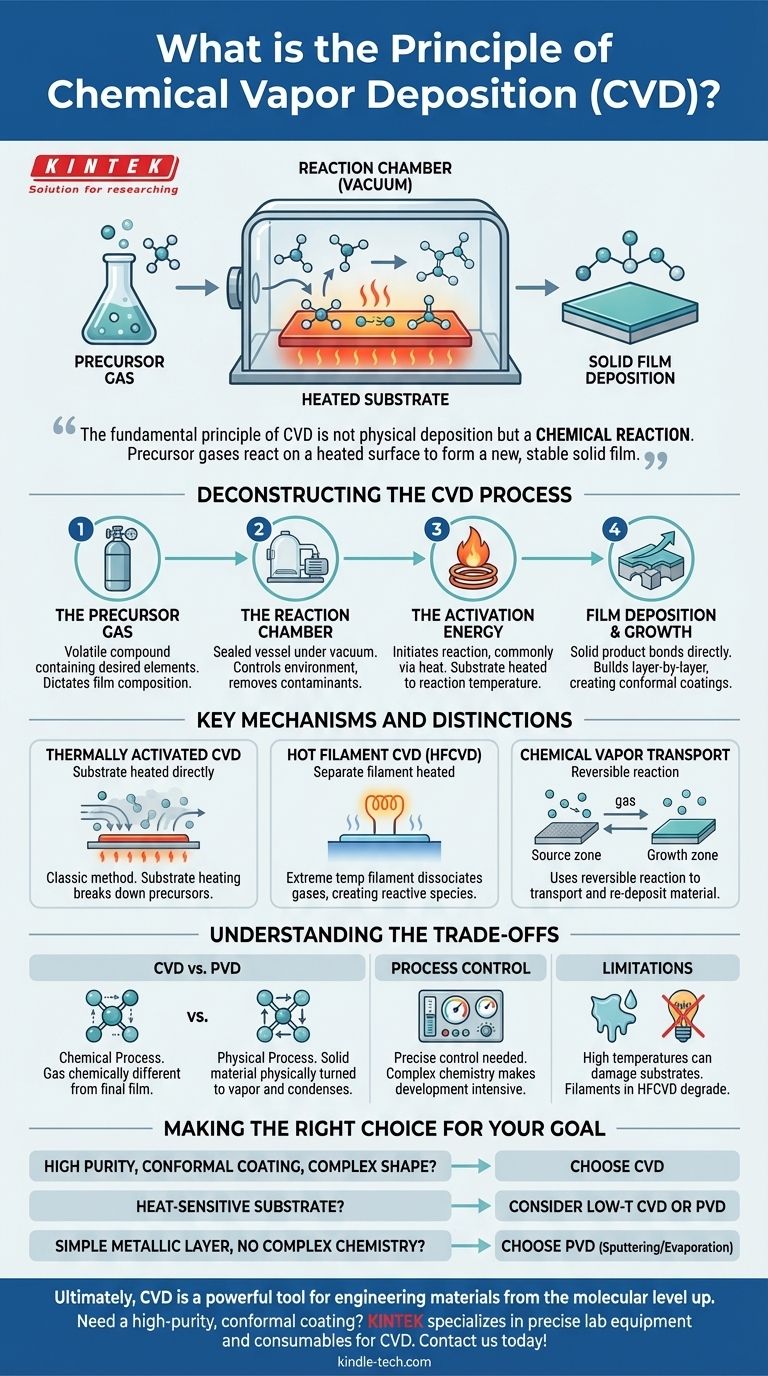

At its core, chemical vapor deposition (CVD) is a manufacturing process that transforms gaseous molecules, known as precursors, into a solid material that deposits as a thin film onto the surface of a substrate. This transformation is driven by a chemical reaction, which is typically activated by high temperatures within a controlled environment like a vacuum chamber. The result is a highly pure and uniform coating built atom by atom.

The fundamental principle of CVD is not physical deposition but a chemical reaction. Precursor gases are introduced into a chamber where they react or decompose on a heated surface, forming a new, stable solid film that bonds directly to the substrate.

Deconstructing the CVD Process

To truly understand CVD, we must break it down into its essential stages. Each step is critical for controlling the final properties of the deposited film.

The Precursor Gas

A precursor is a volatile chemical compound that contains the elements you wish to deposit. It is introduced into the reaction chamber in a gaseous state.

The choice of precursor is vital, as it dictates the composition of the final film and the conditions (like temperature and pressure) required for the reaction.

The Reaction Chamber

The entire process takes place within a reaction chamber. This is typically a sealed vessel where environmental conditions can be precisely controlled.

Most often, the chamber is kept under a vacuum. This serves two purposes: it removes unwanted atmospheric gases that could cause contamination and helps transport the precursor gases toward the substrate surface.

The Activation Energy

A chemical reaction will not occur without an input of energy. In CVD, this is known as activation energy, and it is most commonly supplied by heat.

The substrate is often heated to a specific reaction temperature. When the precursor gases come into contact with this hot surface, they gain enough energy to either decompose or react with other gases to form the desired solid material.

Film Deposition and Growth

Once the chemical reaction is triggered, the solid product bonds directly to the substrate surface.

This process continues over time, with the material building up layer by layer. Because it is driven by a surface chemical reaction, CVD is exceptionally good at creating conformal coatings, meaning it can evenly coat complex, non-flat shapes.

Key Mechanisms and Distinctions

While heat is the most common activator, different CVD methods use various techniques to initiate the chemical reaction. This distinction is crucial for understanding the process's versatility.

Thermally Activated CVD

This is the classic form of CVD. The substrate is heated, providing the thermal energy needed to break down the precursor gases that flow over it. The solid by-products of this thermal decomposition form the film.

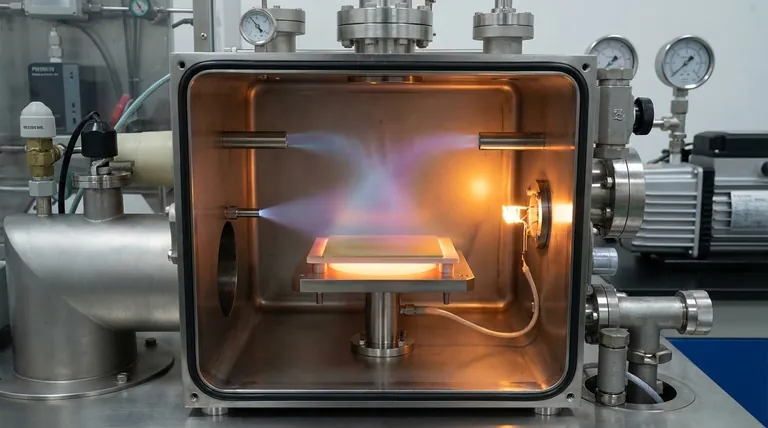

Hot Filament CVD (HFCVD)

In some cases, a separate element is heated instead of the entire substrate. For example, in HFCVD, a refractory metal filament (like tungsten or tantalum) is heated to extreme temperatures (over 2000 K).

This hot filament efficiently dissociates precursor gases, like methane (CH4) and hydrogen (H2), creating reactive chemical species that then deposit onto a nearby, often cooler, substrate.

Chemical Vapor Transport

This method uses a reversible chemical reaction. In a "source zone," a solid material is reacted with a transport agent to become a gas. This gas then moves to a "growth zone" (often at a different temperature), where the reverse reaction occurs, re-depositing the original material as a pure, crystalline film.

Understanding the Trade-offs

No process is perfect. Understanding the limitations of CVD is essential for its proper application and for comparing it to other techniques.

CVD vs. Physical Vapor Deposition (PVD)

The most important distinction is that CVD is a chemical process, while PVD is a physical one.

In PVD, a solid material is physically turned into a vapor (by heating or ion bombardment) and then simply condenses on the substrate. In CVD, the precursor gas is chemically different from the final film, which is created via a reaction at the surface.

Process Control and Complexity

The quality of a CVD film depends on precise control over gas flow rates, temperature, and pressure. The underlying chemistry can be complex, making process development more intensive than for some PVD techniques.

Material and Substrate Limitations

The high temperatures required for many thermal CVD processes can damage sensitive substrates like plastics or certain alloys. Furthermore, the filaments used in methods like HFCVD can degrade over time, introducing impurities or causing process drift.

Making the Right Choice for Your Goal

Selecting a deposition technology depends entirely on the desired outcome for your material or component.

- If your primary focus is a highly pure, dense, and conformal coating on a complex shape: CVD is often the superior choice because the film is built through a surface chemical reaction.

- If you are working with a heat-sensitive substrate: You must consider low-temperature CVD variants or an alternative like PVD, which can often be performed at lower temperatures.

- If your goal is to deposit a simple metallic layer without complex chemistry: A physical process like PVD (sputtering or evaporation) may be a more direct and cost-effective solution.

Ultimately, chemical vapor deposition is a powerful tool for engineering materials from the molecular level up.

Summary Table:

| CVD Process Stage | Key Function |

|---|---|

| Precursor Gas | Supplies the elements for the film in a volatile form. |

| Reaction Chamber | Provides a controlled, often vacuum, environment for the process. |

| Activation Energy | Initiates the chemical reaction (typically via heat). |

| Film Deposition | Builds the solid material layer-by-layer on the substrate surface. |

Need a high-purity, conformal coating for your research or production?

The principles of CVD make it ideal for creating uniform films on complex geometries. At KINTEK, we specialize in providing the precise lab equipment and consumables needed to implement CVD and other deposition techniques effectively. Our expertise can help you select the right system for your specific substrate and material goals, ensuring optimal performance and results.

Contact us today to discuss how our solutions can enhance your laboratory's capabilities. Reach out via our contact form to get started!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What is thin film deposition in semiconductor manufacturing? Build Advanced Chips with Atomic Precision

- What is the Chemical Vapour Deposition (CVD) method for growing diamonds? Discover Precision Carbon Synthesis

- What is sputtering for thin film deposition? A Guide to High-Performance Coating Technology

- What is the CVD method of deposition? Grow High-Purity Thin Films from Gas

- What are the methods of CVD deposition? Choosing the Right Energy Source for Your Thin Film

- What is deposition process in semiconductor manufacturing? Building Microchips Layer by Layer

- How do chemical vapor deposition (CVD) systems optimize high-performance strain thin films? Master Atomic Precision

- What is the temperature of polysilicon in LPCVD? Master the Key to Film Structure and Performance