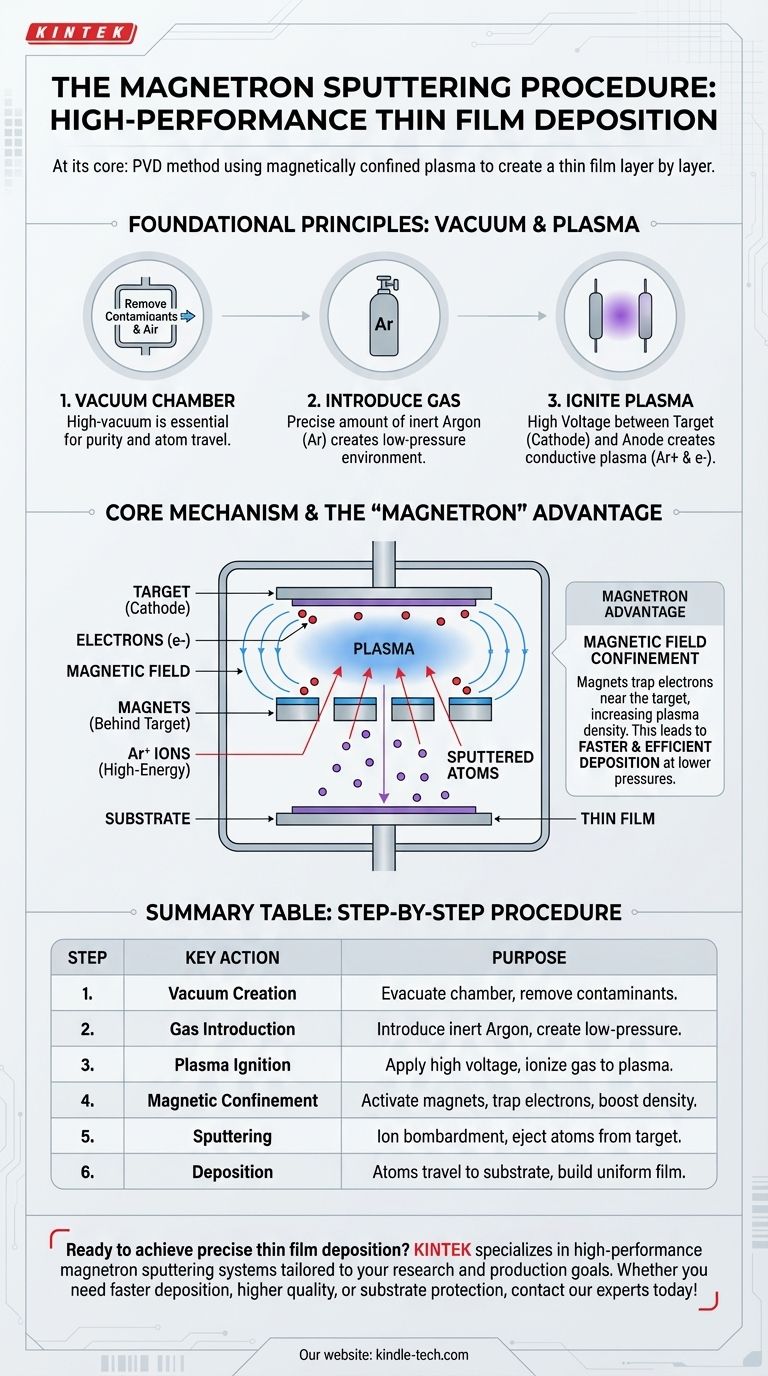

At its core, the procedure of magnetron sputtering is a physical vapor deposition (PVD) method that uses a magnetically confined plasma to create a thin film. In a vacuum, high-energy ions bombard a source material, known as the target, causing atoms to be ejected or "sputtered." These liberated atoms then travel and deposit onto a substrate, building the desired coating layer by layer.

The critical innovation of magnetron sputtering is not just the sputtering itself, but the strategic use of magnetic fields. These fields trap electrons near the target, dramatically increasing plasma density, which leads to significantly faster and more efficient film deposition at lower pressures.

The Foundational Principles: From Vacuum to Plasma

To understand the procedure, we must first establish the environment and the initial state. The entire process hinges on creating a carefully controlled plasma.

Creating the Environment: The Vacuum Chamber

Magnetron sputtering begins inside a high-vacuum chamber. This step is non-negotiable, as removing air and other contaminants is essential for the purity of the final film and allows sputtered atoms to travel freely to the substrate.

Introducing the Sputtering Gas

Once a high vacuum is achieved, a small, precisely controlled amount of an inert gas, most commonly argon (Ar), is introduced into the chamber. This gas creates a low-pressure environment that will eventually be transformed into a plasma.

Igniting the Plasma

A high DC or RF voltage is applied between two electrodes inside the chamber: the cathode (which is the target material) and the anode. This powerful electric field energizes the argon gas, stripping electrons from the argon atoms.

This process of ionization creates a plasma—a glowing, electrically conductive gas composed of positively charged argon ions (Ar+) and free electrons (e-). This is often visible as a characteristic colorful glow discharge.

The Core Mechanism: The Sputtering and Deposition Cycle

With the plasma established, the physical process of creating the film begins. This cycle involves ejecting atoms from the source and depositing them onto the destination.

The Target: The Source of Your Film

The material you wish to deposit is fabricated into a "target," which is set up as the negatively charged cathode. The positive argon ions from the plasma are naturally accelerated by the electric field directly toward this negative target.

Ion Bombardment and Atom Ejection

These high-energy argon ions collide with the target surface with significant force. The impact is energetic enough to physically knock out or sputter atoms from the target material, ejecting them into the vacuum chamber.

Deposition: Building the Film

The sputtered atoms, being neutral, are unaffected by the electric or magnetic fields. They travel in a straight line through the low-pressure environment until they strike a surface. When they land on the substrate, they cool, condense, and bond, gradually building a thin, uniform film.

The "Magnetron" Advantage: Supercharging the Process

Simple sputtering works, but it is slow and inefficient. The addition of a magnetron—an array of strong permanent magnets placed behind the target—revolutionizes the process.

The Problem with Simple Sputtering

In a simple sputtering system without magnets, free electrons are quickly drawn to the anode. This limits their ability to collide with and ionize neutral argon atoms, resulting in a low-density plasma and a very slow deposition rate.

The Solution: Magnetic Field Confinement

The magnetron's magnetic field is designed to be parallel to the target surface. This field forces the highly mobile, lightweight electrons into a spiral, cycloidal path, effectively trapping them in a zone directly in front of the target.

How Magnets Increase Efficiency

By trapping electrons, their path length before reaching the anode increases by orders of magnitude. This drastically raises the probability that an electron will collide with and ionize a neutral argon atom.

This chain reaction creates an intensely dense plasma concentrated precisely where it's needed most: right in front of the target. This high density of argon ions leads to a much higher rate of bombardment, a higher sputtering yield, and a significantly faster deposition rate.

Understanding the Trade-offs

While powerful, magnetron sputtering is not a universal solution. Understanding its limitations is key to its successful application.

Target Material and Power Source

For DC sputtering, the most common variant, the target must be electrically conductive. Insulating or ceramic materials can be sputtered, but this requires a more complex and typically slower setup using Radio Frequency (RF) power.

Line-of-Sight Deposition

Sputtering is a line-of-sight process. Sputtered atoms travel in straight lines, meaning they cannot coat areas that are in a "shadow." Complex 3D objects often require sophisticated rotation and manipulation to achieve uniform coverage.

Process Control

The quality of the final film is highly sensitive to process parameters like gas pressure, voltage, power, and the distance between the target and substrate. Achieving repeatable, high-quality results demands precise control over the entire system.

Making the Right Choice for Your Goal

The procedural steps are a means to an end. Your specific goal determines which aspects of the process are most critical.

- If your primary focus is deposition speed: The key takeaway is the efficiency of the magnetic confinement. A stronger or better-designed magnetic array leads to a denser plasma and faster film growth.

- If your primary focus is film quality and density: The low operating pressure enabled by the magnetron is the critical factor, as it reduces gas incorporation into the film and leads to a denser, purer coating.

- If your primary focus is protecting sensitive substrates: The process's ability to operate at lower temperatures is paramount. The magnetic field confines the plasma's heat near the target, preventing overheating and damage to delicate materials like polymers.

By understanding the interplay of vacuum, plasma, and magnetic fields, you can effectively leverage the magnetron sputtering procedure to engineer high-performance thin films.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1. Vacuum Creation | Evacuate the chamber | Remove contaminants, allow free atom travel |

| 2. Gas Introduction | Introduce inert gas (Argon) | Create low-pressure environment for plasma |

| 3. Plasma Ignition | Apply high voltage to cathode/anode | Ionize gas to create conductive plasma |

| 4. Magnetic Confinement | Activate magnets behind target | Trap electrons, increase plasma density |

| 5. Sputtering | Ion bombardment of target | Eject atoms from source material |

| 6. Deposition | Atoms travel to substrate | Build uniform thin film layer by layer |

Ready to achieve precise thin film deposition in your lab? KINTEK specializes in high-performance magnetron sputtering systems and laboratory equipment. Whether you need faster deposition rates, higher film quality, or protection for sensitive substrates, our solutions are tailored to meet your specific research and production goals. Contact our experts today to discuss how our sputtering technology can advance your work!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Electron Beam Evaporation Coating Conductive Boron Nitride Crucible BN Crucible

People Also Ask

- What is the principle of operation of physical Vapour deposition technique? A Guide to High-Performance Thin Films

- How is metal deposited on a surface using sputter deposition? A Guide to High-Quality Thin Film Coating

- What are the physical methods for synthesis and thin film deposition? Choose the Right PVD Technique

- What is the work of chemical vapour deposition method? A Guide to Building High-Performance Thin Films

- What equipment is needed for chemical vapor deposition? A Guide to the Essential CVD System Components

- What is chemical vapor deposition method of nanomaterials? Build Atom-by-Atom with Precise Control

- Why is a high-vacuum reaction chamber necessary for CVD of TiO2? Master Film Purity & Precision

- How much does a chemical vapor deposition system cost? From $50k to $10M+