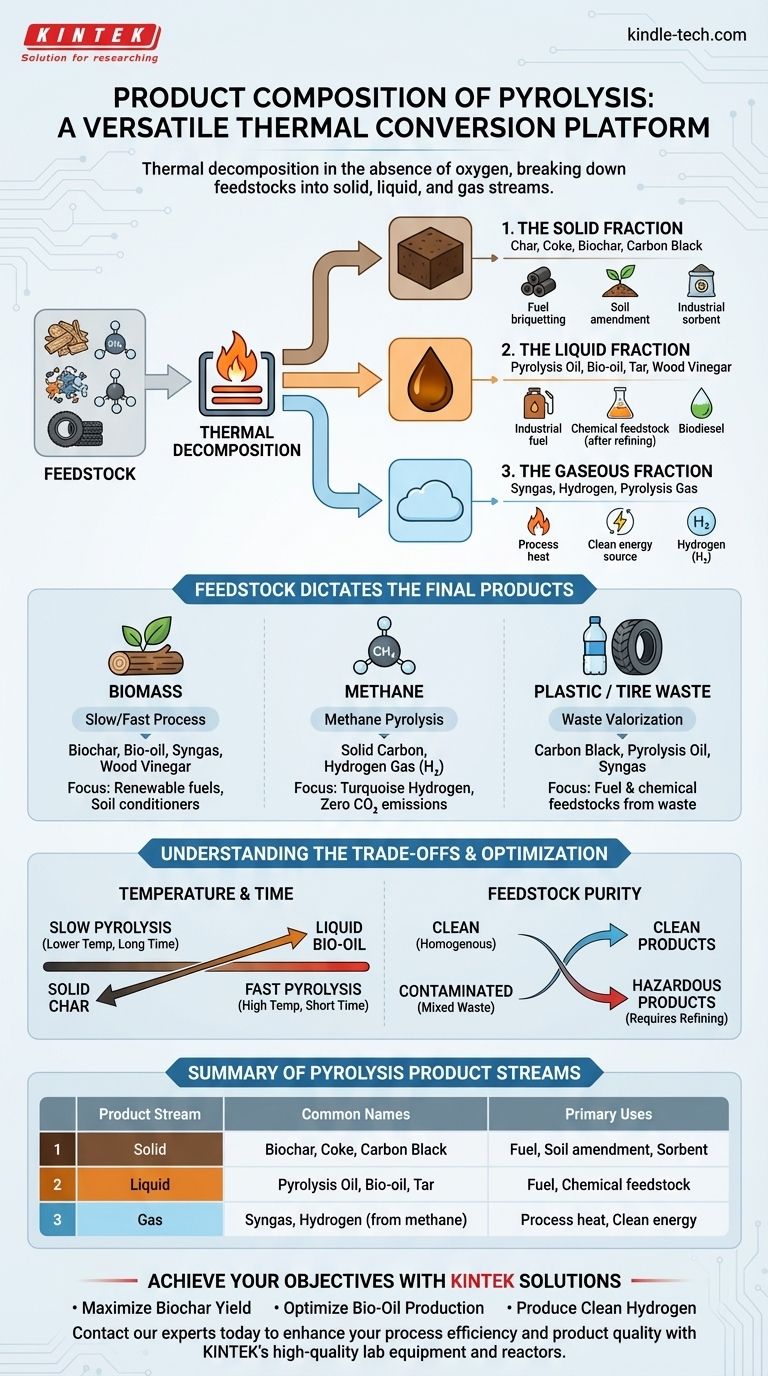

The product composition of pyrolysis is consistently broken down into three primary streams: a solid char, a liquid oil, and a non-condensable gas. The specific nature, yield, and chemical makeup of these products, however, depend entirely on the initial material (feedstock) being processed and the conditions of the pyrolysis reaction.

Pyrolysis is best understood not as a single process with a fixed output, but as a versatile thermal conversion platform. It deconstructs a feedstock into its core components, invariably producing a solid, a liquid, and a gas, whose specific characteristics and value are dictated by the input material.

The Three Core Product Streams of Pyrolysis

At its heart, pyrolysis is thermal decomposition in the absence of oxygen. This process breaks down complex materials, resulting in products across all three states of matter.

The Solid Fraction: Char and Coke

This is the solid, carbon-rich residue left after the volatile components have been driven off.

Its name and properties change based on the feedstock. From biomass, it is called biochar or biocoal. From other materials like tires or coal, it's often referred to as coke or carbon black.

This solid product is valuable as a fuel for briquetting, an agricultural soil amendment (biochar), or an industrial material like a sorbent.

The Liquid Fraction: Pyrolysis Oil and Bio-oil

This fraction is a complex liquid mixture, often called pyrolysis oil, bio-oil, tar, or wood vinegar.

It is composed of hundreds of different organic compounds. Bio-oil, for instance, contains a significant amount of water and oxygenated organic compounds, from simple acetic acid to complex phenols.

This liquid can be used as an alternative industrial fuel or, with significant refining, upgraded into higher-value products like biodiesel or other chemicals.

The Gaseous Fraction: Syngas and Hydrogen

This stream consists of gases that do not condense back into a liquid upon cooling. This is often called pyrolysis gas or syngas.

This gas is typically high in energy content and is very often recycled and consumed directly by the pyrolysis plant itself to generate the heat needed for the process, creating a more energy-efficient system.

In specific cases, like methane pyrolysis, this gaseous product is the primary goal. The process breaks methane (CH₄) down into solid carbon and highly valuable gaseous hydrogen (H₂).

How Feedstock Dictates the Final Products

The most common point of confusion regarding pyrolysis products stems from the feedstock. The output from pyrolyzing wood is fundamentally different from that of pyrolyzing natural gas.

Biomass Pyrolysis

When processing organic materials like wood, agricultural waste, or manure, the outputs are specifically termed biochar, bio-oil, and syngas.

The liquid fraction also includes byproducts like wood vinegar, which has applications in agriculture. The focus is often on creating renewable fuels and soil conditioners.

Methane Pyrolysis

This is a much cleaner and more specific process. The input is a single molecule (methane), and the outputs are simply two high-value products: solid carbon and hydrogen gas.

This is often called "turquoise hydrogen" production, valued for generating hydrogen without direct carbon dioxide emissions.

Plastic or Tire Pyrolysis

Processing waste plastics or old tires yields a solid carbon black (a form of coke), a liquid pyrolysis oil that chemically resembles crude oil, and a flammable syngas.

The goal here is typically waste valorization, turning a low-value or negative-value waste stream into valuable fuel and chemical feedstocks.

Understanding the Trade-offs

The yields of these three product streams are not fixed. They can be manipulated by changing the process conditions to favor one output over another.

The Impact of Temperature and Time

The rate of heating and the final temperature dramatically influence the product distribution.

Slow pyrolysis (lower temperatures, longer processing times) maximizes the production of the solid char. This is the preferred method for making biochar for agriculture.

Fast pyrolysis (high temperatures, very short processing times) is optimized to maximize the yield of liquid bio-oil, often at the expense of the char.

Product Quality and Contamination

The purity of the input material is critical. A clean, homogenous feedstock like wood chips will produce a relatively clean set of products.

Contaminated feedstocks, such as mixed municipal waste or treated lumber, will result in oils and chars that contain unwanted or hazardous chemicals, requiring costly and complex downstream refining before they can be used safely.

How to Apply This to Your Goal

Your objective determines which feedstock and process conditions are most appropriate.

- If your primary focus is carbon sequestration or soil amendment: Prioritize slow pyrolysis of biomass to maximize the yield and quality of biochar.

- If your primary focus is creating a liquid fuel substitute: Utilize fast pyrolysis of biomass, plastics, or tires to maximize the output of pyrolysis oil.

- If your primary focus is producing clean hydrogen: Concentrate specifically on methane pyrolysis, which directly separates methane into hydrogen gas and solid carbon.

Ultimately, understanding pyrolysis is about matching the right material and the right thermal process to your desired end products.

Summary Table:

| Product Stream | Common Names (Varies by Feedstock) | Primary Uses |

|---|---|---|

| Solid | Biochar, Coke, Carbon Black | Fuel briquetting, soil amendment, industrial sorbent |

| Liquid | Pyrolysis Oil, Bio-oil, Tar | Industrial fuel, chemical feedstock (after refining) |

| Gas | Syngas, Hydrogen (from methane) | Process heat, clean energy source |

Ready to tailor a pyrolysis process for your specific feedstock and product goals?

At KINTEK, we specialize in providing high-quality lab equipment and consumables for pyrolysis research and development. Whether you are optimizing biochar production from biomass, generating hydrogen via methane pyrolysis, or valorizing plastic waste, our reactors and analytical tools deliver the precise temperature control and reliability you need.

Let us help you achieve your objectives:

- Maximize Biochar Yield: For carbon sequestration and soil health.

- Optimize Bio-Oil Production: For renewable liquid fuels.

- Produce Clean Hydrogen: For next-generation energy solutions.

Contact our experts today to discuss how KINTEK's solutions can enhance your pyrolysis process efficiency and product quality.

Visual Guide

Related Products

- Customizable Laboratory High Temperature High Pressure Reactors for Diverse Scientific Applications

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- High Temperature Constant Temperature Heating Circulator Water Bath Chiller Circulator for Reaction Bath

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Wall Mounted Water Distillation Unit

People Also Ask

- Why must SCWG reactors maintain a specific heating rate? Protect Your High-Pressure Vessels from Thermal Stress

- What is the advantage of using high-pressure hydrothermal reactors to treat biomass waste? Efficient Resource Recovery

- Why are high-precision pressure sensors and temperature control systems critical for hydrothermal reaction equilibrium?

- What role does a PTFE-lined stainless steel autoclave play in the synthesis of BiOBr precursor nanosheets?

- Why use high-pressure reactors for food waste pretreatment? Boost Hydrogen Production Efficiency Today!