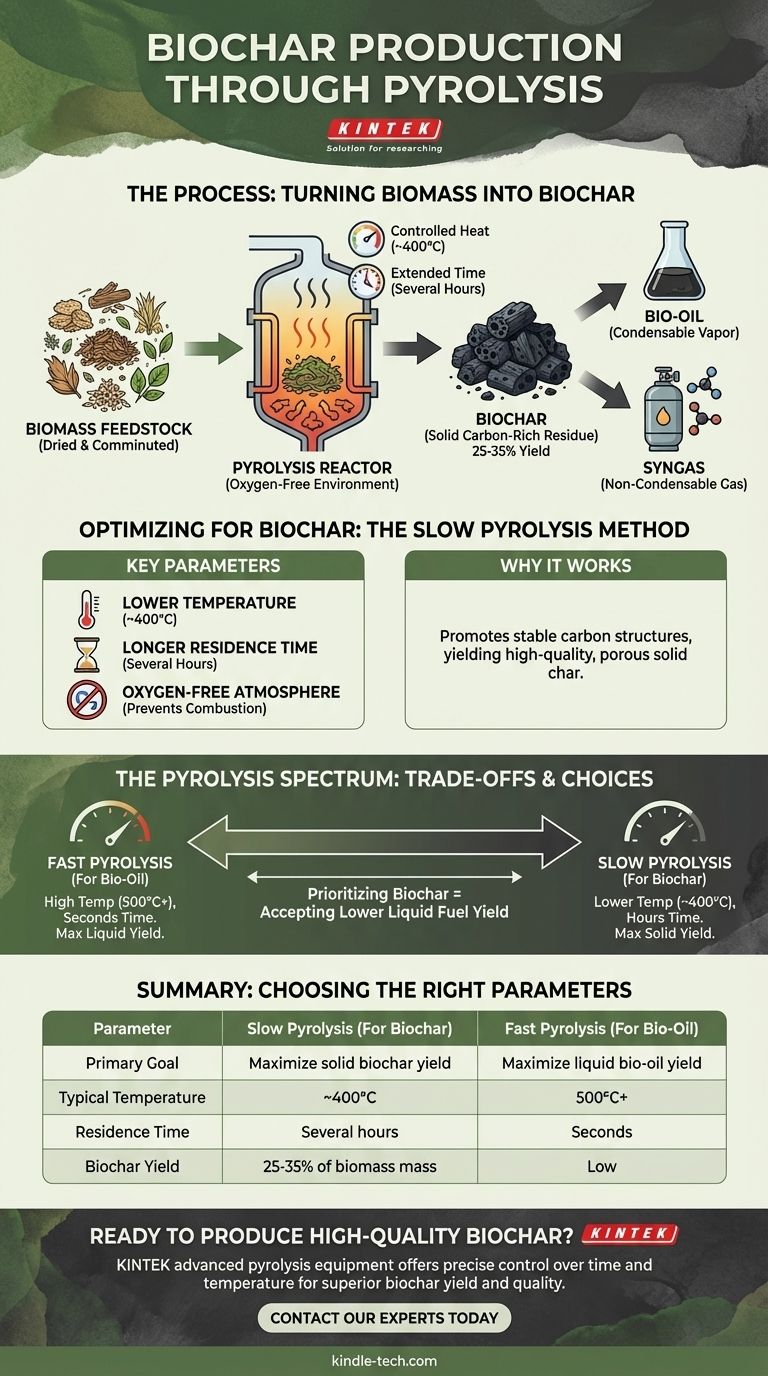

Biochar production through pyrolysis is a thermochemical process where organic material, or biomass, is heated to high temperatures in an environment with little to no oxygen. This process, specifically a method called slow pyrolysis, uses controlled heat and extended time to transform the biomass into a stable, carbon-rich solid known as biochar.

The fundamental principle of producing biochar is intentionally slowing down the pyrolysis process. By carefully controlling lower temperatures and longer heating times, the conversion of biomass is optimized to yield a high-quality, solid carbon char rather than maximizing the output of liquid bio-oil or combustible gas.

The Core Mechanism of Pyrolysis

To understand biochar production, we must first understand the general process of pyrolysis. It is a method of thermal decomposition that changes the chemical composition of a material.

What is Pyrolysis?

Pyrolysis involves heating a substance in an inert, oxygen-free atmosphere. The intense heat breaks down the complex molecules within the biomass into three primary products:

- A solid, carbon-rich residue (char)

- A liquid, condensable vapor (bio-oil)

- A non-condensable gas (syngas)

The Role of an Oxygen-Free Environment

The absence of oxygen is critical. If oxygen were present, the biomass would simply burn (combust), releasing its energy and carbon primarily as heat and carbon dioxide. By excluding oxygen, we force the material to decompose thermally, preserving much of the carbon in a solid form.

Optimizing for Biochar: The Slow Pyrolysis Method

While all pyrolysis yields some char, producing high-quality biochar requires a specific set of conditions known as slow pyrolysis. This method is deliberately managed to maximize the solid output.

Temperature as a Critical Control

Biochar production typically uses lower temperatures, often around 400°C. This contrasts with "fast pyrolysis," which can exceed 700°C to maximize liquid bio-oil. The lower heat promotes the formation of stable carbon structures that make up biochar.

The Importance of Residence Time

Slow pyrolysis involves a much longer residence time, meaning the biomass is held at the target temperature for an extended period, often for several hours. This long duration allows the thermal decomposition to proceed slowly and completely, resulting in a more uniform and stable char.

Feedstock Preparation and Yields

Before pyrolysis, the biomass feedstock is typically dried and undergoes mechanical comminution (being broken down into smaller, more uniform pieces). In a typical slow pyrolysis process, biochar can account for 25-35% of the final product mass, with the remainder being bio-gas and a small amount of bio-oil.

Understanding the Trade-offs: Char vs. Bio-Oil

The parameters you choose for pyrolysis create a direct trade-off between the types of products you generate. You are essentially deciding which output to prioritize.

The Pyrolysis Spectrum

Think of pyrolysis as a spectrum. On one end, you have fast pyrolysis: high temperatures and very short residence times (seconds) to maximize the production of liquid bio-oil. On the other end, you have slow pyrolysis: lower temperatures and long residence times (hours) to maximize the yield of solid biochar.

Yield Compromises

A decision to optimize for biochar is a decision to accept a lower yield of liquid fuels. The process conditions that create a stable, porous carbon solid are fundamentally different from those that produce the highest volume of condensable vapors for bio-oil.

Making the Right Choice for Your Goal

The specific parameters of pyrolysis are not arbitrary; they are chosen to create a final product with desired characteristics for a specific application.

- If your primary focus is soil fertility and carbon sequestration: Prioritize slow pyrolysis with lower temperatures (around 400°C) and long residence times to produce a stable, high-yield biochar.

- If your primary focus is producing liquid biofuels: Opt for fast pyrolysis with higher temperatures (500°C+) and very short residence times to maximize the yield of condensable bio-crude oil.

Ultimately, mastering biochar production is about understanding how to manipulate time and temperature to dictate the final form of carbon.

Summary Table:

| Parameter | Slow Pyrolysis (For Biochar) | Fast Pyrolysis (For Bio-Oil) |

|---|---|---|

| Primary Goal | Maximize solid biochar yield | Maximize liquid bio-oil yield |

| Typical Temperature | ~400°C | 500°C+ |

| Residence Time | Several hours | Seconds |

| Biochar Yield | 25-35% of biomass mass | Low |

Ready to produce high-quality biochar for your specific application?

KINTEK specializes in advanced pyrolysis equipment designed for precise control over temperature and residence time, enabling you to optimize your process for superior biochar yield and quality. Whether your goal is enhancing soil fertility or advancing carbon sequestration projects, our robust and reliable lab equipment is engineered to meet your research and production needs.

Contact our experts today to discuss how our solutions can help you achieve your biochar production goals!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Non Consumable Vacuum Arc Induction Melting Furnace

- Boron Nitride (BN) Crucible for Phosphorous Powder Sintered

People Also Ask

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy