In essence, plastic pyrolysis is a chemical recycling process that breaks down plastic waste using high heat in an oxygen-free environment. This thermal decomposition converts complex plastic polymers into simpler, valuable products, primarily a liquid fuel known as pyrolysis oil. It provides a way to manage plastic types that are difficult or impossible to recycle mechanically.

Pyrolysis is not about melting plastic; it's about fundamentally deconstructing it at a molecular level. It transforms low-value, often non-recyclable plastic waste into a usable hydrocarbon fuel, offering a powerful alternative to landfills or incineration.

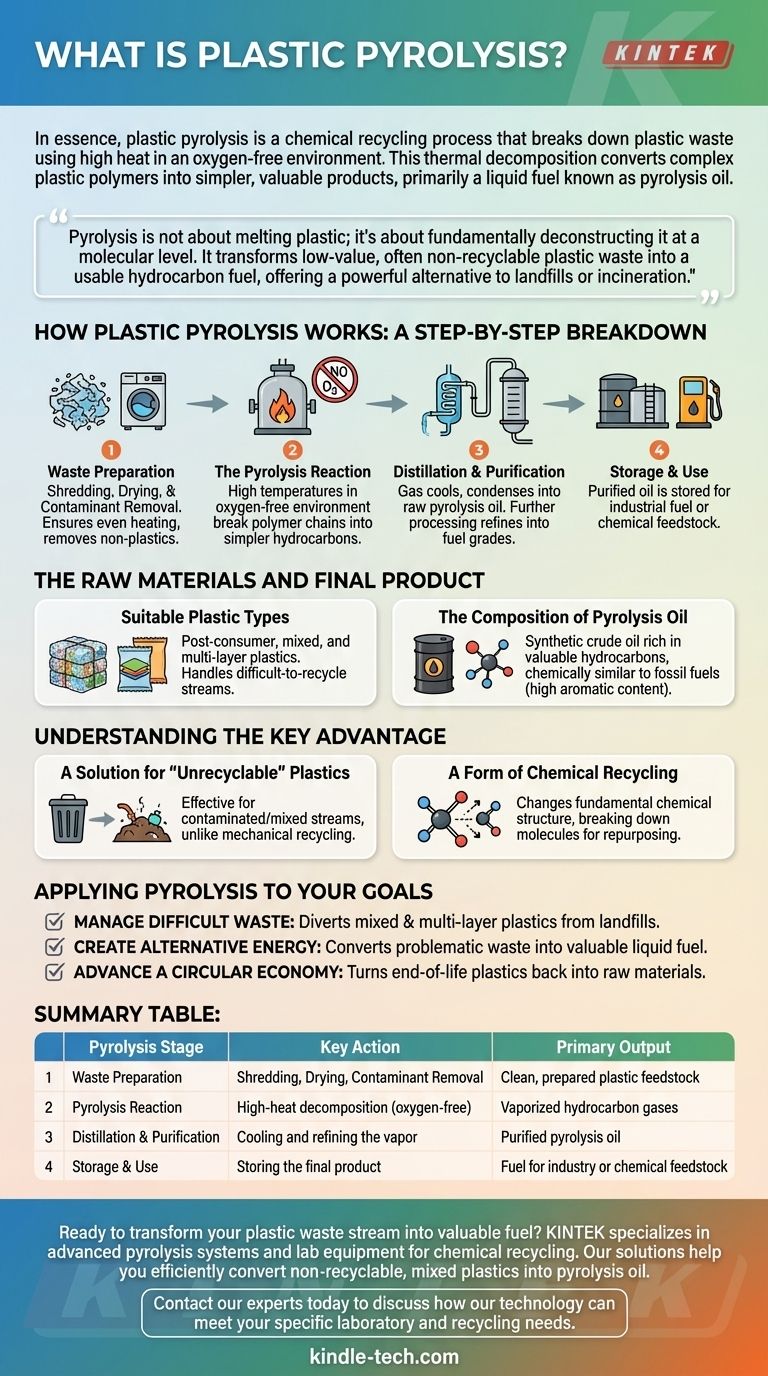

How Plastic Pyrolysis Works: A Step-by-Step Breakdown

The conversion of plastic waste into fuel follows a structured, multi-stage industrial process. Each step is designed to purify the input material and optimize the final output.

Step 1: Waste Preparation

Before the reaction can begin, the raw plastic waste must be prepared. This typically involves shredding the plastic into smaller, more uniform pieces to ensure even heating.

The shredded material is then dried to remove moisture. Crucially, any non-plastic contaminants like metal, glass, or organic matter are separated and removed.

Step 2: The Pyrolysis Reaction

The prepared plastic is fed into a reactor, which is then sealed to create an oxygen-free environment. The material is heated to very high temperatures, causing the long polymer chains that make up the plastic to break apart into smaller, simpler hydrocarbon molecules.

Step 3: Distillation and Purification

The hot gas mixture created during pyrolysis is channeled out of the reactor and cooled. As it cools, the gas condenses into a liquid—the raw pyrolysis oil.

This crude oil often requires further processing, such as distillation and purification, to separate different fuel grades and remove any remaining impurities.

Step 4: Storage and Use

The final, purified oil is stored and is ready to be dispatched for use as an industrial fuel or as a feedstock for producing new chemicals.

The Raw Materials and Final Product

The effectiveness of pyrolysis lies in its ability to handle a wide range of plastic waste that challenges traditional recycling methods.

Suitable Plastic Types

Pyrolysis is particularly well-suited for complex waste streams. This includes post-consumer plastics, waste segregated from municipal solid waste, and rejects from mechanical recycling facilities.

It is especially valuable for processing multi-layer packaging and mixed plastics contaminated with PET or PVC, which are notoriously difficult to recycle otherwise.

The Composition of Pyrolysis Oil

The primary output is a synthetic crude oil. Scientific analysis using methods like GC-MS and FT-IR confirms that this oil is rich in valuable hydrocarbons.

Its composition is a mix of high aromatic content along with aliphatic and other hydrocarbon compounds, making it chemically similar to fossil-derived fuels.

Understanding the Key Advantage

Pyrolysis occupies a specific and critical niche within the broader landscape of waste management and recycling. It is not a replacement for all other methods but a complementary solution for a specific problem.

A Solution for "Unrecyclable" Plastics

The core value of pyrolysis is its ability to handle contaminated and mixed plastic streams. Mechanical recycling requires clean, sorted, single-stream plastics to be effective. Pyrolysis provides a viable pathway for the complex materials left behind.

A Form of Chemical Recycling

Unlike mechanical recycling, which simply melts and reforms plastic, pyrolysis is a form of chemical recycling. It changes the fundamental chemical structure of the material, breaking it down into its constituent molecules. This allows those molecules to be repurposed as fuel or new chemical building blocks.

Applying Pyrolysis to Your Goals

Understanding the process helps clarify how it can be applied to solve specific environmental and economic challenges.

- If your primary focus is managing difficult waste: Pyrolysis is an effective technology for diverting mixed and multi-layer plastics from landfills.

- If your primary focus is creating alternative energy: The process directly converts a problematic waste stream into a valuable liquid fuel source.

- If your primary focus is advancing a circular economy: Pyrolysis acts as a powerful chemical recycling tool, turning end-of-life plastics back into valuable raw materials.

Ultimately, plastic pyrolysis serves as a critical technology for unlocking the hidden value in plastic waste that would otherwise be lost.

Summary Table:

| Pyrolysis Stage | Key Action | Primary Output |

|---|---|---|

| Waste Preparation | Shredding, Drying, and Contaminant Removal | Clean, prepared plastic feedstock |

| Pyrolysis Reaction | High-heat decomposition in an oxygen-free reactor | Vaporized hydrocarbon gases |

| Distillation & Purification | Cooling and refining the vapor | Purified pyrolysis oil |

| Storage & Use | Storing the final product | Fuel for industry or chemical feedstock |

Ready to transform your plastic waste stream into valuable fuel?

KINTEK specializes in advanced pyrolysis systems and lab equipment for chemical recycling. Our solutions help you efficiently convert non-recyclable, mixed plastics into pyrolysis oil, reducing landfill waste and creating a new revenue stream.

Contact our experts today to discuss how our technology can meet your specific laboratory and recycling needs.

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the principle of rotary kiln? Mastering Continuous Thermal Processing

- What are the types of pyrolysis reactors used in industry? Choose the Right Technology for Your Product

- What equipment is used in pyrolysis? Choosing the Right Reactor for Your Feedstock and Products

- What biomass is used in pyrolysis? Selecting the Optimal Feedstock for Your Goals

- What is the purpose of a calciner? Boost Efficiency in High-Temperature Processing