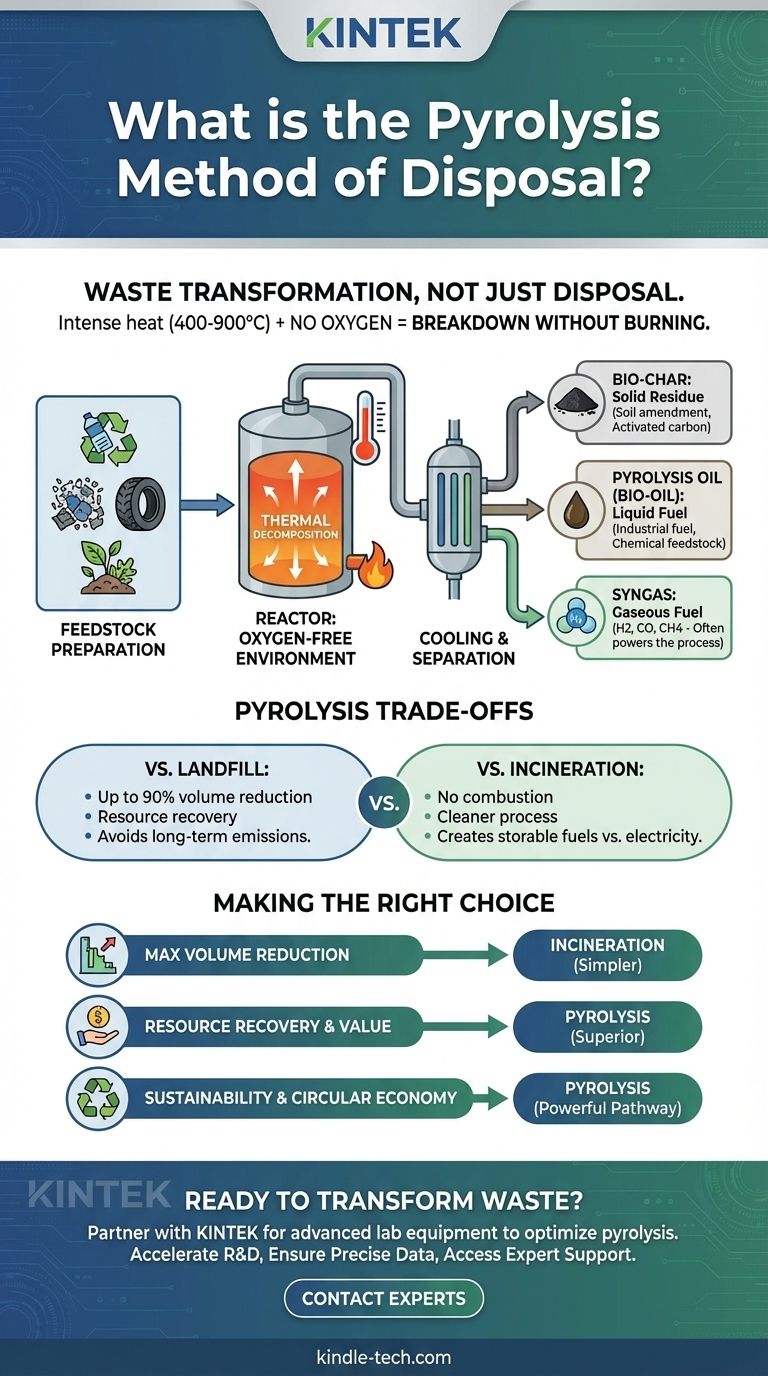

In essence, pyrolysis is a method of disposal that uses intense heat to break down materials without burning them. It works by feeding waste streams like plastics, tires, or biomass into a sealed, oxygen-free reactor. The high temperatures cause the material to decompose into a mixture of valuable solid, liquid, and gaseous products, effectively transforming waste into a resource.

Pyrolysis should not be viewed merely as waste disposal, but as waste transformation. Unlike incineration, which destroys waste through combustion, pyrolysis thermally deconstructs it in an oxygen-starved environment to recover raw materials and energy.

How Pyrolysis Works: A Step-by-Step Breakdown

Pyrolysis is a thermochemical process, meaning it uses heat to create a chemical change. The entire system is engineered to control this change with precision.

The Core Principle: Heat Without Oxygen

The defining feature of pyrolysis is heating materials to very high temperatures (typically 400-900°C) in the absence of oxygen.

This is the critical distinction from incineration. Without oxygen, the material cannot combust or "burn." Instead, the complex molecules within the waste are broken down into simpler, more stable compounds.

The Input: Feedstock Preparation

The process begins with the "feedstock"—the waste material designated for treatment. This material is often shredded, dried, and cleaned to ensure a consistent size and moisture content, which is crucial for an efficient reaction.

The Reactor: The Heart of the Process

The prepared feedstock is fed into a specialized reactor vessel. Here, it is heated externally. As the temperature climbs, the material undergoes thermal decomposition, breaking apart into vapors and solid char.

The Output: Separating Valuable Products

The mixture of hot gases and vapors is drawn out of the reactor and cooled. This cooling process separates the outputs into three distinct streams: a non-condensable gas, a condensable liquid, and the solid char left behind in the reactor.

The Products of Pyrolysis: From Waste to Value

The primary advantage of pyrolysis is its ability to create useful products from materials that would otherwise end up in a landfill.

Bio-char: The Solid Residue

The solid, carbon-rich material left after the process is called bio-char. It is a stable form of carbon that can be used as a potent soil amendment to improve fertility and water retention or processed further to create high-grade activated carbon for filtration systems.

Pyrolysis Oil (Bio-oil): The Liquid Fuel

When the hot vapors are cooled, they condense into a dark liquid known as pyrolysis oil or bio-oil. This liquid can be refined into specialty chemicals or used directly as an industrial fuel in furnaces and boilers, similar to a heavy fuel oil.

Syngas: The Gaseous Fuel

The portion of the gas stream that does not condense is called syngas (synthesis gas). This gas is a mixture of hydrogen, carbon monoxide, and methane. It has fuel value and is often looped back to provide the heat for the pyrolysis reactor, making the process partially or even fully self-sustaining.

Understanding the Trade-offs

While promising, pyrolysis is a complex industrial process with specific benefits and challenges compared to other disposal methods.

Pyrolysis vs. Landfill

Pyrolysis offers a dramatic improvement over landfills. It reduces waste volume by up to 90%, recovers valuable resources, and avoids the long-term environmental liability of landfill leachate and methane gas emissions.

Pyrolysis vs. Incineration

This comparison is more nuanced. Incineration burns waste with oxygen to generate heat, which can produce electricity. Pyrolysis breaks waste down without oxygen to create storable fuels (oil, char, gas). Pyrolysis can be considered a cleaner process, as the controlled, oxygen-free environment prevents the formation of many of the dioxins and furans associated with conventional combustion.

The Key Challenges: Cost and Complexity

Pyrolysis plants represent a significant capital investment and require sophisticated control systems to manage temperature, pressure, and feedstock quality. The economic viability often depends on the market value of its outputs—bio-oil, syngas, and bio-char—which can fluctuate.

Making the Right Choice for Your Goal

Selecting the appropriate technology depends entirely on your primary objective for waste management.

- If your primary focus is maximum waste volume reduction with simpler technology: Traditional waste-to-energy incineration may be a more straightforward option, though it forgoes product recovery.

- If your primary focus is resource recovery and creating storable, valuable products: Pyrolysis is the superior choice, as it is fundamentally designed to convert waste liabilities into tangible assets.

- If your primary focus is environmental sustainability and a circular economy: Well-managed pyrolysis offers a powerful pathway to reduce landfill dependence and recover materials with a potentially cleaner emissions profile than incineration.

Ultimately, pyrolysis reframes the concept of waste from an endpoint to a starting point for new value.

Summary Table:

| Product | Description | Common Uses |

|---|---|---|

| Bio-char | Solid, carbon-rich residue | Soil amendment, activated carbon for filtration |

| Pyrolysis Oil (Bio-oil) | Condensed liquid from vapors | Industrial fuel, feedstock for specialty chemicals |

| Syngas | Non-condensable gas (H2, CO, CH4) | Fuel for heating the pyrolysis reactor |

Ready to transform your waste streams into valuable resources?

KINTEK specializes in advanced laboratory equipment and consumables for researching and optimizing pyrolysis processes. Whether you are developing new feedstock or analyzing the quality of bio-oil, char, and syngas, our precision tools are designed to meet the rigorous demands of your laboratory.

Partner with KINTEK to:

- Accelerate R&D with reliable lab-scale reactors and analytical instruments.

- Ensure precise data for process optimization and product quality control.

- Access expert support for your specific application challenges.

Contact our experts today to discuss how our solutions can support your pyrolysis and waste transformation projects.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- 1700℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What important safety precaution should be taken when using a melting point apparatus? Avoid Burns and Explosions

- What mechanical properties are affected by heat treatment? Master Hardness, Strength, and Toughness

- What are the temperature capabilities of low-temperature freezers? A Guide to Stable Sample Preservation

- What is maintenance and how can you maintain the laboratory? Boost Lab Reliability & Data Integrity

- How does multizone heating work? Achieve Custom Comfort and Energy Savings

- What are the important parameters which affect the sputtering process? Master Thin Film Deposition Control

- What are the products of pyrolysis? A Guide to Biochar, Bio-Oil, and Syngas

- What is the rotary method of extraction? Harness High-Volume Thermal Processing for Your Materials