There is no single deposition rate for Chemical Vapor Deposition (CVD). The rate is entirely dependent on the specific CVD technique being used, the material being deposited, and the process parameters. Rates can range from a few angstroms per minute for highly precise methods to several micrometers per minute for high-throughput industrial coatings.

The central challenge in thin-film deposition is managing the trade-off between speed and quality. High-speed CVD techniques are excellent for bulk coating but often sacrifice film perfection, while precision techniques like Atomic Layer Deposition (ALD) offer ultimate control at the cost of extremely slow throughput.

Why "CVD Rate" Isn't One Number

Chemical Vapor Deposition is not a single process but a family of related technologies. Each is optimized for different outcomes, with deposition rate being a primary differentiator.

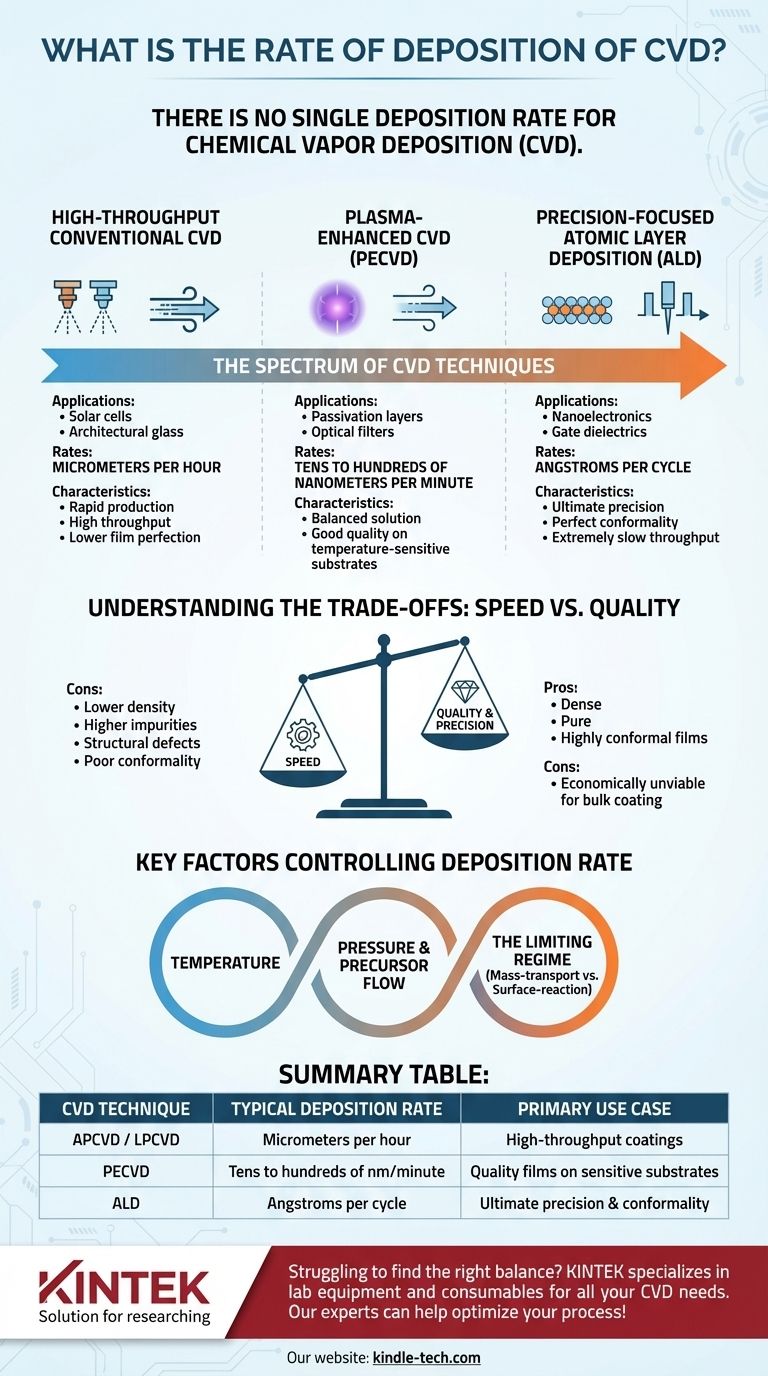

The Spectrum of CVD Techniques

Understanding the rate requires categorizing the specific method.

High-Throughput Conventional CVD

Techniques like Atmospheric Pressure CVD (APCVD) and Low-Pressure CVD (LPCVD) are the workhorses for applications where speed is critical. They operate by flowing precursor gases over a heated substrate, leading to a continuous reaction.

Think of this like spray painting: it's fast and covers a large area quickly, but achieving a perfectly uniform, angstrom-thin layer is difficult. These methods are often measured in micrometers per hour.

Plasma-Enhanced CVD (PECVD)

PECVD occupies a middle ground. It uses a plasma to break down precursor gases into reactive radicals at much lower temperatures than conventional CVD.

This allows for the deposition of high-quality films on temperature-sensitive substrates. The rate is typically slower than LPCVD but significantly faster than ALD, often falling in the range of tens to hundreds of nanometers per minute.

Precision-Focused Atomic Layer Deposition (ALD)

ALD is a subset of CVD that provides the ultimate control. Instead of a continuous flow, it uses sequential, self-limiting pulses of precursor gases. Each pulse deposits exactly one atomic or molecular layer.

This is like building a structure one LEGO brick at a time. It is incredibly precise and creates perfectly uniform, conformal films, but it is also extremely slow. ALD rates are measured in angstroms per cycle, with a full cycle taking from seconds to a minute.

Key Factors Controlling Deposition Rate

Beyond the choice of technique, several process parameters directly influence how fast a film grows.

Temperature

In most CVD processes, higher temperatures increase the reaction kinetics, leading to a faster deposition rate. However, there is often an upper limit where film quality degrades or gas-phase reactions begin to create particles.

Pressure & Precursor Flow

Increasing the concentration of reactants (precursors) by raising the pressure or flow rate can increase the deposition speed. This is only true if the process is limited by the amount of available reactant.

The Limiting Regime

A process is either mass-transport-limited (limited by how fast reactants get to the surface) or surface-reaction-limited (limited by how fast the reaction occurs on the surface). Understanding which regime your process is in is critical for optimization. In a reaction-limited process, for instance, increasing gas flow will not increase the deposition rate.

Understanding the Trade-offs: Speed vs. Quality

Choosing a CVD method is a classic engineering decision that balances competing priorities. There is no universally "best" option.

The Cost of Speed

High deposition rates often come at a price. Rapid growth can lead to films with lower density, higher impurity levels, more structural defects, and poor conformality—the ability to uniformly coat complex, three-dimensional surfaces.

The Price of Precision

Techniques like ALD deliver near-perfect films that are dense, pure, and highly conformal. This precision is essential for modern nanoelectronics. However, the extremely low throughput makes it economically unviable for applications that simply require a thick, protective coating.

Making the Right Choice for Your Goal

Selecting the correct CVD process requires aligning the technique's strengths with your primary objective.

- If your primary focus is rapid production and high throughput (e.g., solar cells, architectural glass): An APCVD or LPCVD process that prioritizes deposition speed in micrometers per hour is the most logical choice.

- If your primary focus is quality films on sensitive substrates (e.g., passivation layers, optical filters): PECVD offers a balanced solution, providing good film quality at lower temperatures with moderate deposition rates.

- If your primary focus is ultimate precision and perfect conformality (e.g., gate dielectrics in advanced transistors): ALD is the only viable option, despite its extremely slow, angstrom-per-cycle deposition rate.

Ultimately, understanding this fundamental trade-off between deposition speed and film perfection is the key to mastering thin-film engineering.

Summary Table:

| CVD Technique | Typical Deposition Rate | Primary Use Case |

|---|---|---|

| APCVD / LPCVD | Micrometers per hour | High-throughput coatings (e.g., solar cells) |

| PECVD | Tens to hundreds of nm/minute | Quality films on sensitive substrates |

| ALD | Angstroms per cycle | Ultimate precision & conformality (e.g., nanoelectronics) |

Struggling to find the right balance between deposition speed and film quality for your project? KINTEK specializes in lab equipment and consumables for all your CVD needs. Whether you require high-throughput systems or precision ALD tools, our experts can help you select the perfect solution to achieve your specific coating goals. Contact our team today to discuss how we can optimize your thin-film deposition process!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory CVD Boron Doped Diamond Materials

People Also Ask

- What is the mechanism of CVD deposition? A Guide to Surface-Controlled Film Growth

- What is the DC sputtering method? A Guide to Thin Film Deposition for Conductive Coatings

- What is the CVD process of silicon? A Guide to High-Purity Silicon Film Deposition

- What is chemical bath deposition also called? A Guide to Chemical Solution Deposition

- How do a precision thermostat and a platinum-rhodium thermocouple collaborate? Master AACVD Thermal Stability

- What is the thin film process for semiconductors? A Guide to PVD, CVD, and ALD Techniques

- What is the inert gas used in sputtering? Maximize Your Thin-Film Deposition Efficiency

- What are the advantages of CVD technique over other deposition processes? Superior Conformal Coating for Complex 3D Parts