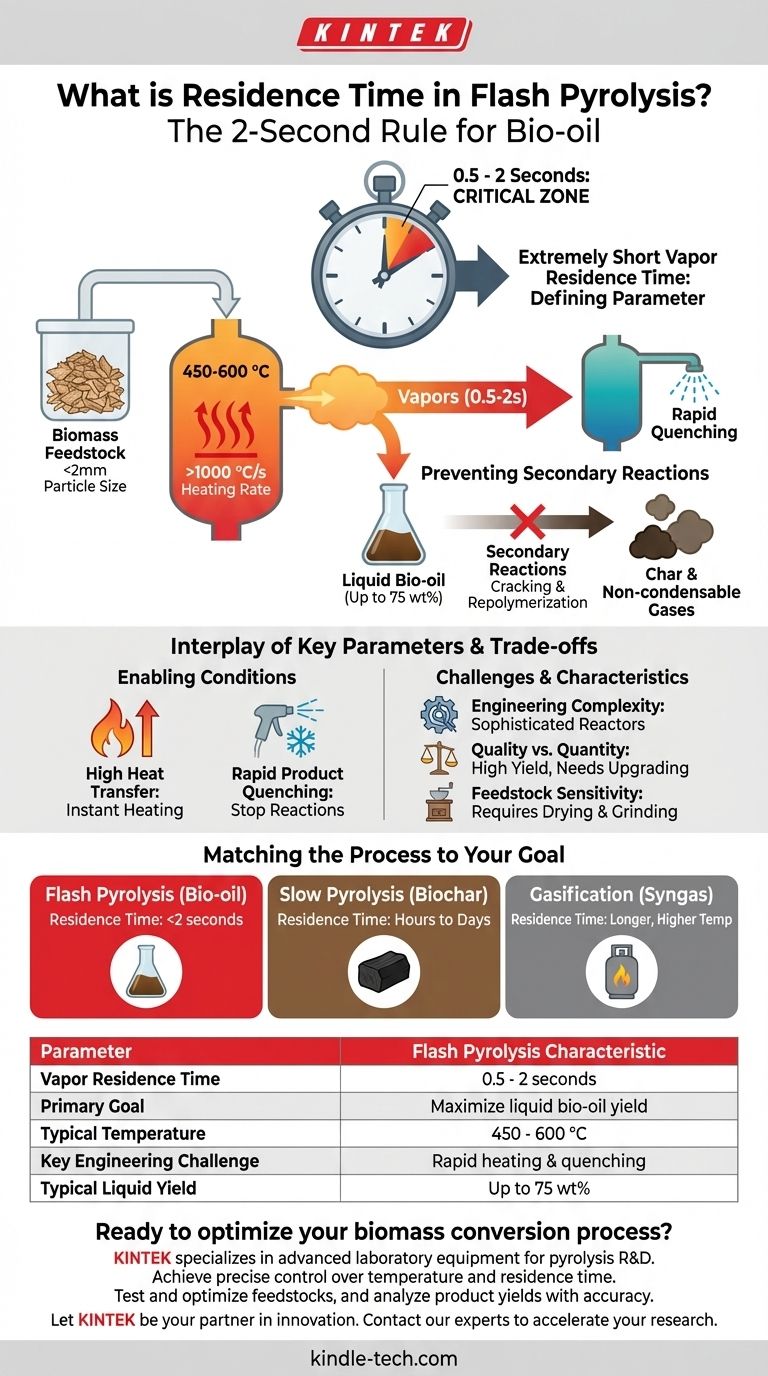

In flash pyrolysis, the vapor residence time is extremely short, typically lasting between 0.5 and 2 seconds. This rapid duration is the most critical and defining parameter of the process. It is deliberately engineered to maximize the production of liquid bio-oil by rapidly removing decomposition vapors from the hot reactor zone before they can degrade into less valuable products.

The sub-2-second residence time in flash pyrolysis is not an arbitrary parameter; it is a deliberate engineering choice to "freeze" the initial thermal decomposition products as valuable liquid bio-oil, preventing them from undergoing secondary reactions that form more stable, but less desirable, char and non-condensable gases.

Why Residence Time is the Defining Factor

To understand flash pyrolysis, you must understand that controlling time is the primary goal. The entire process is designed around minimizing the duration that volatile compounds spend at high temperatures.

The Goal: Maximizing Liquid Bio-oil

The principal objective of flash pyrolysis is to convert solid biomass into a liquid intermediate. This liquid, known as bio-oil or pyrolysis oil, can be stored, transported, and upgraded into advanced biofuels and biochemicals.

The Mechanism of Rapid Decomposition

At moderate temperatures (typically 450-600 °C), biomass components like cellulose, hemicellulose, and lignin break down into a complex mixture of vapors, aerosols, and some solid char. This initial product slate is rich in condensable organic compounds.

Preventing Secondary Reactions

This is the most critical concept. If these initial vapors remain in the hot reactor for too long (i.e., more than a few seconds), they undergo secondary reactions. These reactions crack the larger, valuable organic molecules into smaller, non-condensable gases (CO, CO2, H2, CH4) or they repolymerize into solid char, drastically reducing the final liquid yield.

The Interplay of Key Process Parameters

A short residence time is meaningless in isolation. It only works in concert with two other extreme conditions that are hallmarks of the flash pyrolysis process.

High Heat Transfer Rates

For a short residence time to be effective, the biomass particles must be heated to the target temperature almost instantaneously. Flash pyrolysis requires very high heating rates (often >1000 °C/s). This is typically achieved by using very small biomass particles (e.g., <2 mm) in specialized reactors like fluidized beds.

Rapid Product Quenching

Just as heating is rapid, cooling must also be extremely fast. After exiting the reactor, the hot vapors and aerosols are immediately quenched (cooled rapidly). This stops the chemical reactions in their tracks and condenses the vapors into the liquid bio-oil product, locking in the high liquid yield.

Understanding the Trade-offs

Achieving these precise conditions presents significant engineering challenges and results in a unique set of product characteristics.

Engineering Complexity

Maintaining a sub-2-second residence time requires sophisticated and expensive reactor designs, such as circulating fluidized bed or ablative reactors. Precise control over temperature, feedstock feed rate, and gas flow is essential and difficult to achieve at a large scale.

Product Quality vs. Quantity

While flash pyrolysis maximizes the quantity of liquid (yields up to 75% by weight are possible), the quality of the raw bio-oil can be poor. It is often acidic, corrosive, thermally unstable, and contains a high amount of water and oxygenated compounds, requiring significant and costly upgrading before it can be used as a drop-in fuel.

Feedstock Sensitivity

The process is highly sensitive to the physical properties of the biomass feedstock. It requires extensive drying and grinding to very small particle sizes to ensure the necessary rapid heat transfer, adding to the overall energy consumption and cost of the operation.

Matching the Process to Your Goal

The residence time you target is fundamentally tied to the primary product you wish to create.

- If your primary focus is maximizing liquid bio-oil yield: You must use flash pyrolysis, ensuring a residence time of less than 2 seconds, coupled with high heating rates and rapid quenching.

- If your primary focus is producing biochar: You must use slow pyrolysis, which employs very long residence times (hours to days) at lower temperatures to deliberately encourage the secondary reactions that form stable carbon.

- If your primary focus is producing syngas: You should look to gasification, which uses higher temperatures and longer residence times specifically to promote the cracking of all tars and chars into simple gas molecules.

Ultimately, controlling residence time is the fundamental lever for directing biomass conversion toward your desired end product.

Summary Table:

| Parameter | Flash Pyrolysis Characteristic |

|---|---|

| Vapor Residence Time | 0.5 - 2 seconds |

| Primary Goal | Maximize liquid bio-oil yield |

| Typical Temperature | 450 - 600 °C |

| Key Engineering Challenge | Rapid heating & quenching |

| Typical Liquid Yield | Up to 75 wt% |

Ready to optimize your biomass conversion process?

At KINTEK, we specialize in advanced laboratory equipment for pyrolysis research and development. Whether you are developing new reactor designs, analyzing bio-oil composition, or scaling up your process, our precise ovens, reactors, and analytical tools are engineered to meet the demanding requirements of flash pyrolysis.

We help you:

- Achieve precise temperature and residence time control.

- Test and optimize feedstocks for maximum efficiency.

- Analyze product yields and quality with accuracy.

Let KINTEK be your partner in innovation. Contact our experts today to discuss how our solutions can accelerate your bio-energy and biochemical research.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy