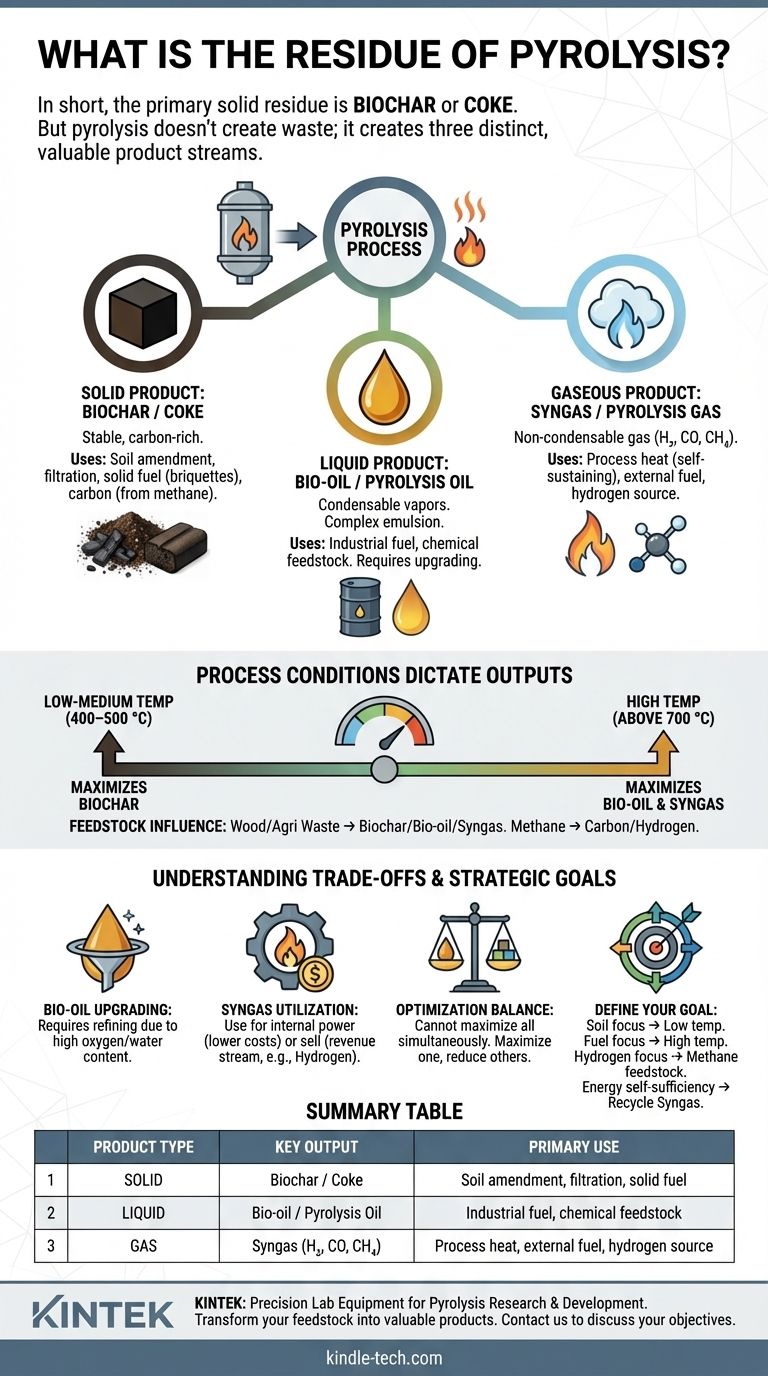

In short, the primary solid residue of pyrolysis is a carbon-rich material called biochar or coke. However, viewing pyrolysis as a process that simply leaves "residue" is a fundamental misunderstanding. Pyrolysis is a thermal conversion technology that transforms a single feedstock into three distinct and often valuable product streams: a solid, a liquid, and a gas.

The core principle to understand is that pyrolysis doesn't create waste; it creates products. The "residue" is a controllable output, and its composition—along with the liquid and gas yields—is determined by the initial material and the specific process conditions you employ.

The Three Primary Products of Pyrolysis

Pyrolysis breaks down organic material using heat in the absence of oxygen. Instead of burning the material, it deconstructs it into its constituent components, which are then captured as three separate products.

The Solid Product: Biochar (or Coke)

This is the most direct answer to what constitutes the "residue." Biochar is a stable, solid material rich in carbon.

It is not waste. It has significant applications in agriculture as a soil amendment, in filtration as a sorbent, and as a solid fuel, often compressed into briquettes. When the feedstock is methane, the solid product is pure carbon.

The Liquid Product: Bio-oil (or Pyrolysis Oil)

As the organic material breaks down, volatile components vaporize and are then condensed back into a liquid. This is known as bio-oil or pyrolysis oil.

This liquid is a complex emulsion of water and hundreds of different oxygenated organic compounds, from simple acetic acid to complex phenols. It can be used as an industrial fuel or further refined into higher-grade biofuels and specialty chemicals. Wood vinegar is another liquid product often collected during biomass pyrolysis.

The Gaseous Product: Syngas (or Pyrolysis Gas)

This non-condensable gas stream, often called syngas, is the third product. It is a mixture of gases like hydrogen, methane, carbon monoxide, and carbon dioxide.

In many pyrolysis plants, this syngas is not considered a residue at all. It is immediately looped back into the system and burned to provide the heat that drives the pyrolysis reaction, making the entire process more energy-efficient and self-sustaining.

How Process Conditions Dictate the Outputs

You can control the ratio of solid, liquid, and gas produced by adjusting the parameters of the pyrolysis process. This gives you direct control over your primary output.

The Critical Role of Temperature

Temperature is the main lever for controlling the product yields.

- Low to Medium Temperatures (400–500 °C): These conditions favor the production of the solid product, maximizing the biochar yield. The process is slower, allowing more carbon to remain in a fixed, solid state.

- High Temperatures (above 700 °C): Higher temperatures cause more aggressive thermal cracking, breaking down molecules more completely. This maximizes the yield of liquid and gaseous products (bio-oil and syngas) at the expense of the solid char.

The Influence of Feedstock

The initial material being processed—known as the feedstock—also fundamentally defines the output.

Pyrolyzing wood or agricultural waste produces the classic biochar, bio-oil, and syngas. In contrast, the pyrolysis of methane is a specialized process designed specifically to break CH₄ into its components: solid carbon and gaseous hydrogen (H₂).

Understanding the Trade-offs

Viewing pyrolysis outputs as products reveals a series of strategic trade-offs rather than a simple waste problem.

Bio-oil Requires Upgrading

While bio-oil is a valuable product, it is not a drop-in replacement for conventional fuels. Its high oxygen and water content make it acidic and unstable. It almost always requires further processing and refining—an added cost and complexity—before it can be widely used.

Syngas: Internal Fuel or External Revenue

There is a direct economic choice to be made with the syngas. Using it to power the plant lowers operational costs and improves energy independence. However, capturing, cleaning, and selling the gas (especially if it's rich in hydrogen) can be an additional revenue stream. The best choice depends on local energy prices and the plant's scale.

Maximizing One Product Reduces Others

You cannot maximize all three outputs simultaneously. Optimizing for high biochar yield inherently means you will get less bio-oil and syngas. The process must be engineered and fine-tuned to meet a specific primary goal, whether it's creating a soil product, a liquid fuel, or hydrogen gas.

Tailoring Pyrolysis to Your Objective

The "residue" of pyrolysis is whatever product you have optimized the system to create. To make the right choice, you must first define your goal.

- If your primary focus is soil amendment or carbon sequestration: Optimize for lower temperatures (400-500 °C) to maximize the yield of solid biochar.

- If your primary focus is creating alternative liquid fuels: Operate at higher temperatures (above 700 °C) to increase the yield of bio-oil, but be prepared for downstream refining costs.

- If your primary focus is generating hydrogen: Use a specific feedstock like methane, as this specialized process yields pure solid carbon and valuable hydrogen gas.

- If your primary focus is waste-to-energy self-sufficiency: Design the system to recycle the syngas to provide the heat needed for the pyrolysis reaction itself.

Ultimately, pyrolysis empowers you to transform a low-value feedstock into higher-value products by carefully controlling the process conditions.

Summary Table:

| Product Type | Key Output | Primary Use |

|---|---|---|

| Solid | Biochar / Coke | Soil amendment, filtration, solid fuel |

| Liquid | Bio-oil / Pyrolysis Oil | Industrial fuel, chemical feedstock |

| Gas | Syngas (H₂, CO, CH₄) | Process heat, external fuel, hydrogen source |

Ready to transform your feedstock into valuable products?

KINTEK specializes in precision lab equipment and consumables for pyrolysis research and development. Whether you're optimizing for biochar yield, bio-oil production, or syngas efficiency, our reactors, temperature controllers, and analytical tools provide the control and reliability you need.

Contact our experts today to discuss how we can support your specific pyrolysis objectives and help you maximize the value from your process.

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Graphite Vacuum Continuous Graphitization Furnace

- Vacuum Cold Trap Direct Cold Trap Chiller

- Double Plate Heating Press Mold for Lab

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- What are the zones in rotary kiln in cement production? Master the Core Process for High-Quality Clinker

- How are composites processed using sintering? Engineered Material Solutions Through Advanced Thermal Bonding

- What is a rotary kiln reactor? A Guide to Industrial Thermal Processing

- What is the meaning of rotary furnace? Achieve Superior Uniformity in Continuous Heat Treatment

- What is the principle of rotary kiln? Mastering Continuous Thermal Processing