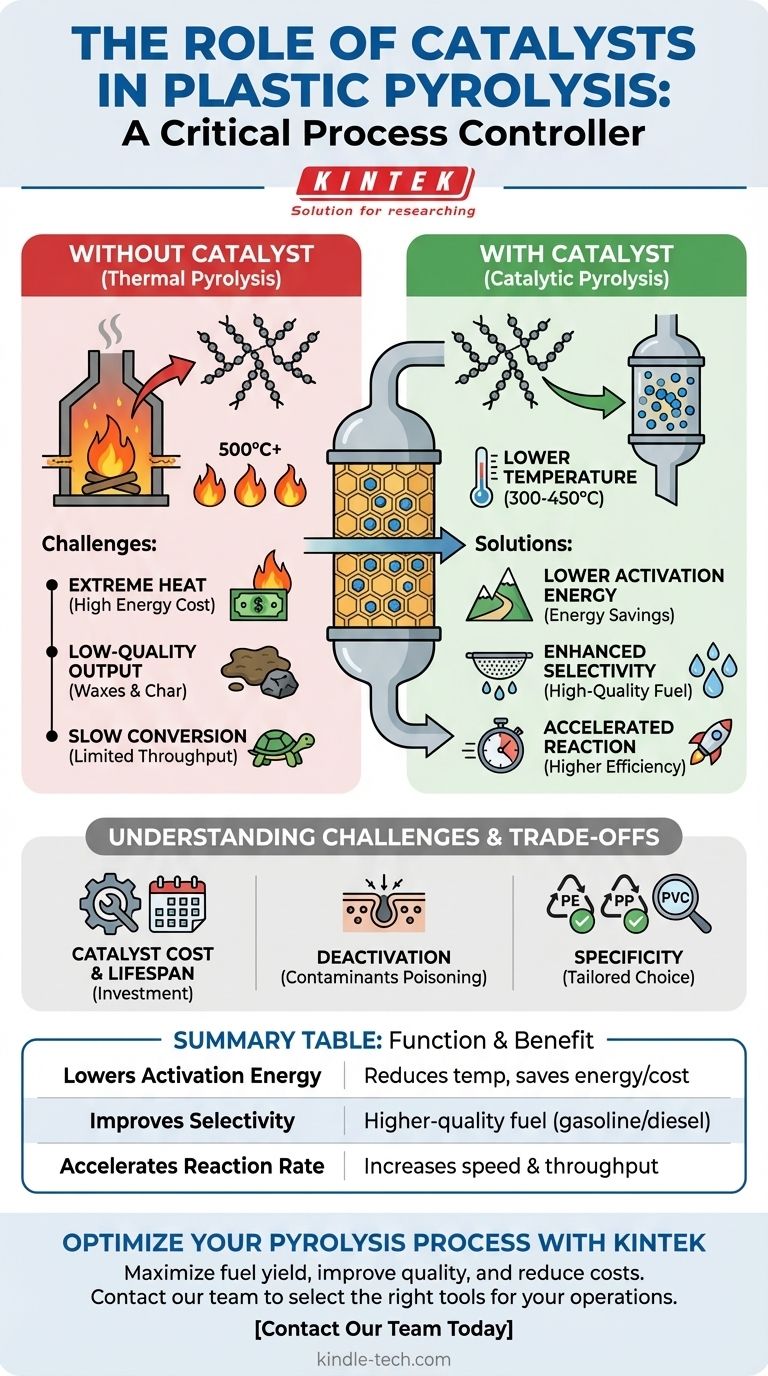

In plastic pyrolysis, a catalyst is not merely an additive; it is a critical process controller. Its primary role is to accelerate and guide the chemical reactions that break down long plastic polymer chains into smaller, more valuable hydrocarbon molecules. By doing so, it lowers the immense energy required for the process and significantly improves the quality and yield of the final liquid oil product.

The fundamental role of a catalyst is to overcome the inherent inefficiencies of basic thermal pyrolysis. It makes the conversion of plastic to oil faster, cheaper by lowering the required temperature, and more precise, steering the reactions to produce a higher-quality liquid fuel instead of a less useful mix of heavy waxes and char.

The Core Problem: Why Pyrolysis Needs a Catalyst

To understand the catalyst's role, we must first understand the challenges of non-catalytic (thermal) pyrolysis. This process relies on brute force—extreme heat—to break down plastic waste.

The Challenge of High Temperatures

Without a catalyst, plastic pyrolysis requires extremely high temperatures, often exceeding 500°C. Maintaining these temperatures is energy-intensive, driving up operational costs and reducing the overall energy efficiency of the process.

The Issue of Low-Quality Output

Thermal pyrolysis is an uncontrolled process. It randomly breaks polymer chains, resulting in a wide distribution of molecules, including a significant amount of heavy, waxy compounds and solid char. This low-grade oil requires costly and complex secondary refining before it can be used as a fuel.

The Slow Speed of Conversion

Relying solely on heat to break down stable plastic polymers is a slow process. This limits the throughput of a pyrolysis plant, affecting its economic viability and ability to process large volumes of waste.

How a Catalyst Solves These Problems

A catalyst introduces a level of chemical intelligence to the process, providing an alternative reaction pathway that is faster, more efficient, and more selective.

Lowering the Activation Energy

The single most important function of a catalyst is to lower the "activation energy" of the reaction. Think of it as finding a shortcut through a mountain instead of climbing over the peak. This allows the chemical breakdown of plastic to occur at significantly lower temperatures (often 300-450°C), resulting in substantial energy and cost savings.

Enhancing Cracking Selectivity

Catalysts, particularly microporous materials like zeolites, have a defined pore structure. These pores act as molecular sieves, selectively breaking down long hydrocarbon chains into a narrower, more desirable range of shorter chains, similar to those found in gasoline and diesel. This dramatically increases the quality of the resulting oil.

Accelerating Reaction Rates

By providing an active surface for the chemical reactions to occur, a catalyst dramatically speeds up the rate of plastic decomposition. This allows for a much higher processing rate, making the entire operation more efficient and scalable.

Understanding the Trade-offs and Challenges

While catalysts offer clear advantages, their use is not without complexity. An objective analysis requires acknowledging the associated challenges.

Catalyst Cost and Lifespan

Effective catalysts can be expensive, representing a significant capital investment. Their operational lifespan is finite, and they must eventually be regenerated or replaced, which adds to the long-term operational cost.

The Problem of Deactivation

Plastic waste is rarely pure. Contaminants like chlorine (from PVC), sulfur, and nitrogen can "poison" the catalyst by blocking its active sites. This deactivation reduces its effectiveness over time and is a major technical hurdle in commercial operations.

Catalyst Specificity

There is no single "best" catalyst for all situations. The ideal choice depends heavily on the specific type of plastic being processed (e.g., polyethylene vs. polypropylene) and the desired end product. This requires careful process design and feedstock control.

Making the Right Choice for Your Goal

The decision to use a catalyst and which type to use depends entirely on your operational objectives.

- If your primary focus is maximizing liquid fuel yield and quality: A selective catalyst, such as a ZSM-5 zeolite, is essential to guide the cracking process toward valuable fuel-range hydrocarbons.

- If your primary focus is minimizing operational energy costs: The use of almost any effective catalyst is justified, as the energy savings from lower process temperatures typically outweigh the catalyst's cost over time.

- If your primary focus is processing mixed, contaminated plastic waste: A more robust, contamination-resistant catalyst is necessary, even if it offers slightly lower selectivity, to ensure a reasonable operational lifespan.

Ultimately, incorporating a catalyst transforms plastic pyrolysis from a crude thermal decomposition into a more refined and economically viable chemical conversion process.

Summary Table:

| Function | Benefit |

|---|---|

| Lowers Activation Energy | Reduces required temperature (300-450°C), saving energy and cost. |

| Improves Selectivity | Produces higher-quality liquid fuel (gasoline/diesel range) instead of waxes. |

| Accelerates Reaction Rate | Increases processing speed and plant throughput for better scalability. |

Ready to optimize your plastic pyrolysis process? The right catalyst is key to maximizing fuel yield, improving oil quality, and reducing operational costs. KINTEK specializes in laboratory equipment and consumables for advanced material testing and process development. Our experts can help you select the right tools to evaluate and scale your catalytic pyrolysis operations. Contact our team today to discuss your specific needs and discover how we can support your innovation in waste-to-energy technology.

Visual Guide

Related Products

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Customizable PEM Electrolysis Cells for Diverse Research Applications

- Custom PTFE Teflon Parts Manufacturer for PTFE Buchner Funnel and Triangular Funnel

- Custom PTFE Teflon Parts Manufacturer for Magnetic Stirring Bar

People Also Ask

- How are PTFE gaskets utilized for POEGMA electrolyte conductivity? Ensure Precision in Electrochemical Measurements

- What is the function of PTFE reaction kettle bodies in micro-CSTR systems? Enhance Chemical Stability & Flow

- What are the specific applications of PTFE in micro-batch slug flow systems? Enhance Your Microfluidic Reaction Purity

- What are alloys in simple words? Unlock the Power of Engineered Materials

- Why is PTFE wire used for hanging metal specimens in biodiesel corrosion tests? Ensure Pure Experimental Results