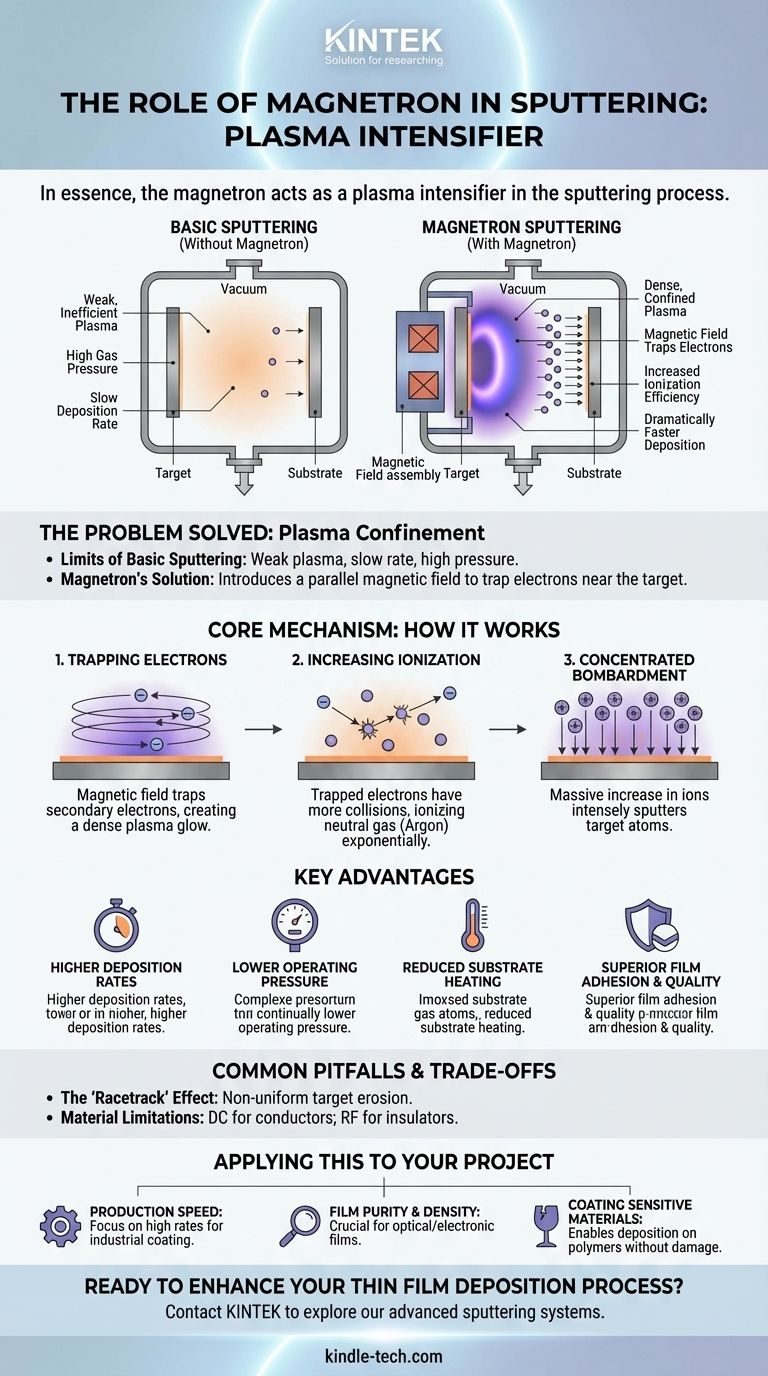

In essence, the magnetron acts as a plasma intensifier in the sputtering process. It uses a carefully configured magnetic field to trap electrons near the surface of the target material. This confinement creates a dense, high-energy plasma that dramatically increases the efficiency of ion bombardment, leading to faster and higher-quality thin film deposition.

The magnetron’s critical role is not simply to help create the plasma, but to confine it. By trapping electrons with a magnetic field, it ensures more gas atoms are ionized and focused onto the target, unlocking higher deposition rates and better film quality at lower operating pressures.

The Problem Magnetron Sputtering Solves

To understand the magnetron's role, it's helpful to first understand sputtering without it.

The Limits of Basic Sputtering

In a simple sputtering system (diode sputtering), a high voltage is applied between a target and a substrate in a low-pressure gas environment, typically Argon.

This creates a plasma, where positive Argon ions are accelerated into the negatively charged target, knocking off atoms that then deposit on the substrate.

However, this process is inefficient. The plasma is weak, requiring relatively high gas pressure, and the deposition rate is very slow.

The Magnetron's Solution: Plasma Confinement

A magnetron sputtering source adds a permanent magnet assembly behind the target. This introduces a magnetic field parallel to the target's surface.

This magnetic field fundamentally changes the dynamics of the plasma and solves the efficiency problem.

The Core Mechanism: How a Magnetron Works

The magnetron's effectiveness comes from how it manipulates electrons within the plasma.

Trapping High-Energy Electrons

When secondary electrons are ejected from the target during ion bombardment, the magnetic field traps them.

It forces these electrons into a spiral path very close to the target surface, preventing them from escaping directly to the chamber walls or substrate. The visible glow of the plasma is a sign of this intense, trapped activity.

Increasing Ionization Efficiency

Because the electrons are trapped and travel a much longer path, their chances of colliding with and ionizing neutral Argon atoms increase exponentially.

This creates a far denser, more self-sustaining plasma right where it's needed—directly in front of the target.

Concentrated Ion Bombardment

The result is a massive increase in the number of positive Argon ions. These ions are then accelerated by the electric field into the target.

This intense, concentrated bombardment sputters target atoms at a much higher rate than is possible with simple diode sputtering.

Understanding the Key Advantages

The magnetron's ability to create a dense, localized plasma provides several critical advantages for thin film deposition.

Higher Deposition Rates

The most immediate benefit is a dramatic increase in the speed at which the film is deposited. This is a direct result of the more efficient ion bombardment of the target.

Lower Operating Pressure

Since the magnetic field makes the plasma self-sustaining and efficient, the system can operate at much lower gas pressures.

Fewer gas atoms in the chamber mean the sputtered atoms travel to the substrate with fewer collisions, resulting in a purer, denser film with better structural integrity.

Reduced Substrate Heating

In basic sputtering, the substrate is bombarded by high-energy electrons, causing significant heating. The magnetron traps most of these electrons near the target.

This keeps the substrate cool, making it possible to coat heat-sensitive materials like plastics and polymers without damage.

Superior Film Adhesion and Quality

The combination of higher-energy sputtered atoms (due to lower pressure) and a cleaner deposition environment results in films that are extremely dense and adhere exceptionally well to the substrate surface.

Common Pitfalls and Trade-offs

While highly effective, the magnetron sputtering process has inherent characteristics that require management.

The "Racetrack" Effect

The confined plasma erodes the target in a distinct groove or "racetrack" pattern, following the path of the trapped electrons.

This leads to non-uniform consumption of the target material, meaning only a fraction of the target is used before it must be replaced.

Material Limitations

The most common method, DC magnetron sputtering, relies on a direct current and only works for electrically conductive target materials.

To sputter insulating or ceramic materials, a more complex method like RF (Radio Frequency) magnetron sputtering is required to prevent charge build-up on the target surface.

How to Apply This to Your Project

Your specific goal will determine which benefit of magnetron sputtering is most important to you.

- If your primary focus is production speed: The magnetron's ability to achieve high deposition rates is its key advantage for industrial-scale coating.

- If your primary focus is film purity and density: The magnetron's efficiency at low operating pressures is crucial for creating high-performance optical, electronic, or protective films.

- If your primary focus is coating sensitive materials: The magnetron's reduced substrate heating is what enables the deposition of metallic or ceramic films onto polymers and other fragile components.

Ultimately, understanding the magnetron's role transforms sputtering from a simple deposition concept into a precise and highly efficient engineering technique for creating advanced materials.

Summary Table:

| Aspect | Without Magnetron | With Magnetron |

|---|---|---|

| Plasma Density | Low, inefficient | High, dense, and confined |

| Deposition Rate | Slow | Dramatically faster |

| Operating Pressure | High | Lower, enabling purer films |

| Substrate Heating | Significant, risk of damage | Reduced, safe for sensitive materials |

| Film Quality | Less dense, weaker adhesion | Superior density and adhesion |

Ready to enhance your thin film deposition process?

At KINTEK, we specialize in advanced lab equipment, including magnetron sputtering systems designed for precision, efficiency, and reliability. Whether you're focused on high-speed production, ultra-pure films, or coating sensitive materials, our solutions are tailored to meet your laboratory's unique needs.

Contact us today to explore how our sputtering technology can elevate your research or production outcomes!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- What are different types of thin films? A Guide to Function, Material, and Deposition Methods

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- What is the difference between PECVD and APCVD? Choose the Right CVD Method for Your Application

- Why does a PECVD vacuum system require both a rotary vane and turbo pump? Ensure High-Purity Coatings

- What is the difference between plasma CVD and thermal CVD? Choose the Right Method for Your Substrate