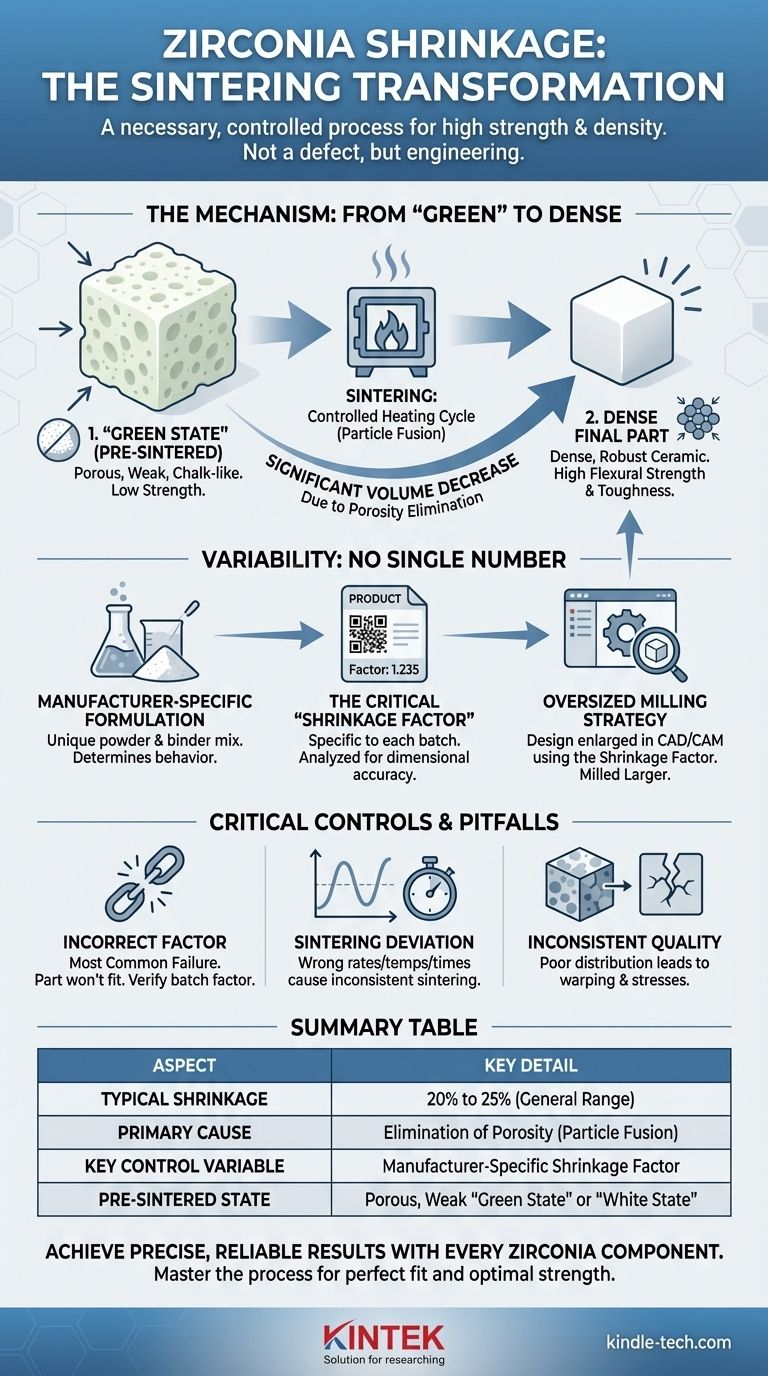

In short, zirconia undergoes significant shrinkage during sintering, a necessary transformation where the material is heated to fuse its particles, reduce porosity, and achieve its final high strength and density. While the exact percentage varies, this shrinkage is a predictable and controlled part of the manufacturing process.

The crucial insight is that zirconia shrinkage is not a defect but a fundamental, engineered part of its processing. This shrinkage is precisely calculated and compensated for during the initial milling stage to ensure the final component achieves its exact intended dimensions and strength.

The Mechanism Behind Zirconia Shrinkage

To understand the final properties of a zirconia component, you must first understand why it changes size so dramatically. The process begins with the material in a porous, pre-sintered state and ends with a dense, solid final form.

From "Green State" to a Dense Final Part

Before sintering, a milled zirconia part exists in its "green state" or "white state." At this stage, it is porous, chalk-like, and easy to mill but possesses very low strength. It is essentially a compressed powder of zirconia particles.

The primary goal of sintering is to transform this weak, porous structure into a fully dense and robust ceramic.

The Role of Heat and Particle Fusion

The sintering process involves a carefully controlled heating cycle. As the temperature rises, the individual zirconia particles do not melt but begin to fuse together at their points of contact.

This atomic diffusion across the boundaries of the particles pulls them closer together, gradually closing the gaps and empty spaces between them.

Eliminating Porosity is the Cause of Shrinkage

The "significant shrinkage" is a direct result of the elimination of this porosity. As the countless microscopic voids between the zirconia particles collapse, the overall volume of the material decreases substantially.

This process increases the material's density, which is directly responsible for its exceptional mechanical properties, such as high flexural strength and fracture toughness.

Why There Is No Single Shrinkage Number

You will not find a single, universal shrinkage value for all zirconia. This variability is intentional and is a key factor in achieving high-precision results.

Manufacturer-Specific Formulation

Each manufacturer develops its own unique formulation of zirconia powder and binders. The specific size and distribution of the zirconia particles in the pre-sintered block or disc dictate its precise shrinkage behavior.

Typically, zirconia shrinkage is in the range of 20% to 25%, but this is only a general guideline.

The Critical "Shrinkage Factor"

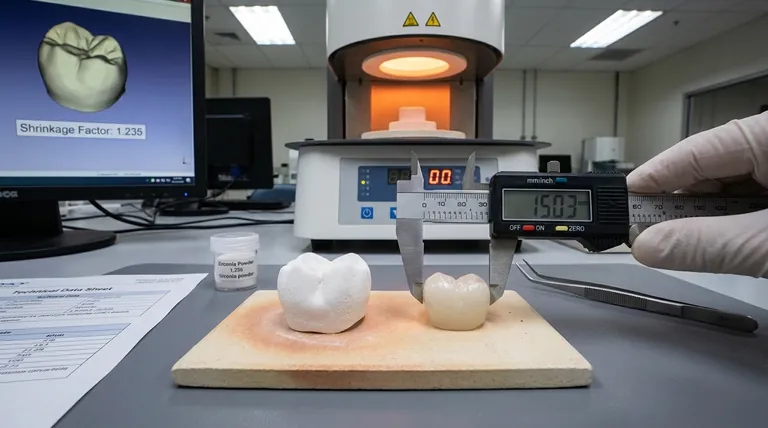

To ensure dimensional accuracy, manufacturers analyze each production batch and print a precise shrinkage factor on the product label or QR code. This number is the key to a successful outcome.

This factor is entered into the CAD/CAM software before milling begins.

The Oversized Milling Strategy

The software uses the specific shrinkage factor to automatically enlarge the design of the component. The part is intentionally milled in an oversized dimension from the green-state block.

During sintering, this oversized part then shrinks down to the exact dimensions specified in the original digital design, ensuring a perfect fit.

Understanding the Trade-offs and Pitfalls

Controlling shrinkage is paramount for success. A failure to manage this single variable will compromise the entire process.

The Impact of an Incorrect Shrinkage Factor

Using the wrong shrinkage factor is the most common cause of failure. If the compensation is inaccurate, a dental crown or industrial component will simply not fit, wasting time and materials. Always verify the factor for the specific disc you are using.

Deviations in the Sintering Cycle

While the shrinkage factor is primary, the sintering cycle itself plays a role. Deviating from the manufacturer's recommended heating rates, peak temperatures, or hold times can lead to incomplete or inconsistent sintering, affecting both the final dimensions and the mechanical integrity of the material.

Inconsistent Material Quality

Using low-quality zirconia blocks with inconsistent particle distribution can result in unpredictable, non-uniform shrinkage. This can cause warping or internal stresses within the final part, making it prone to premature failure.

Making the Right Choice for Your Goal

Achieving predictable shrinkage is about maintaining tight control over your process from digital design to final sintering.

- If your primary focus is clinical or engineering fit: Always use the manufacturer-provided shrinkage factor for the specific batch of zirconia you are milling.

- If your primary focus is material strength: Strictly adhere to the validated sintering protocol to ensure full densification and the development of optimal mechanical properties.

- If your primary focus is process reliability: Regularly calibrate your sintering ovens and implement a workflow that double-checks the shrinkage factor input before every job.

Ultimately, mastering zirconia requires treating shrinkage not as a problem, but as the controllable variable that unlocks the material's unparalleled performance.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Typical Shrinkage Range | 20% to 25% |

| Primary Cause | Elimination of porosity during particle fusion |

| Key Control Variable | Manufacturer-specific shrinkage factor |

| Pre-Sintered State | Porous, weak "green state" or "white state" |

| Result of Shrinkage | High density, strength, and fracture toughness |

Achieve precise, reliable results with every zirconia component.

Mastering the sintering process is critical for ensuring your dental restorations or industrial parts have a perfect fit and optimal strength. KINTEK specializes in the lab equipment and consumables that support this precision.

Our range of high-quality sintering furnaces and accessories are designed for consistent, controlled heating cycles. Partner with us to enhance your workflow reliability and material performance.

Contact KINTEK today to discuss your lab's sintering needs and discover the right solution for you.

Visual Guide

Related Products

- Graphite Vacuum Furnace Negative Material Graphitization Furnace

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

- 1200℃ Muffle Furnace Oven for Laboratory

- Horizontal High Temperature Graphite Vacuum Graphitization Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is a porcelain furnace used for in dentistry? Precision Crafting for Lifelike Dental Restorations

- What is the average lifespan of a dental restoration? Maximize Your Investment with the Right Material

- Are ceramic teeth expensive? Investing in Natural-Looking, Durable Dental Restorations

- What is the sintering temperature for zirconia? Unlock Maximum Strength and Aesthetics

- Why are ceramic crowns so expensive? The Real Cost of a Natural-Looking Smile

- What is the mode of failure most often associated with ceramic dental implants? Understanding Fracture Risk

- If a dental laboratory's ceramic restorations lack ideal aesthetics, what is the first step? Calibrate Your Furnace.

- What factors are important to consider when choosing a dental sintering furnace? Match Your Workflow for Optimal Results