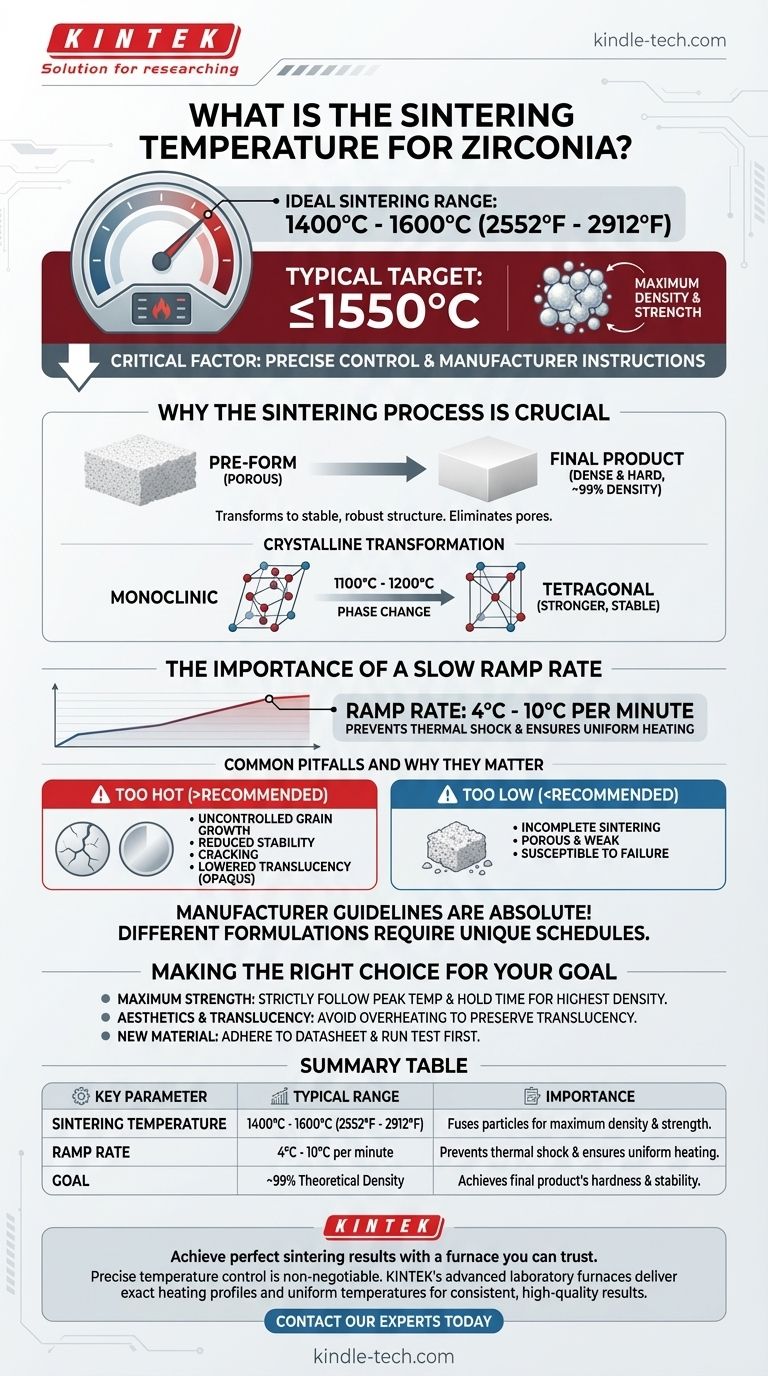

The ideal sintering temperature for zirconia typically falls within a range of 1400°C to 1600°C (2552°F to 2912°F). Most zirconia materials are fired at or below 1550°C to achieve maximum density and strength, which is the primary goal of the sintering process.

While the temperature range is high, the critical factor is not a single number but the precise control of the entire heating process. Following the specific manufacturer's instructions is paramount, as deviation can compromise the material's final strength, stability, and aesthetic properties.

Why the Sintering Process is Crucial

Sintering is a heat treatment that transforms the porous, chalky zirconia pre-form into a dense, hard, and stable final product. The temperature and heating rate directly govern the success of this transformation.

The Goal: Maximum Density and Strength

The primary purpose of firing zirconia at such high temperatures is to achieve maximum densification. During this process, the individual zirconia particles fuse, eliminating pores and creating a solid, robust structure.

Proper sintering brings the material to nearly 99% of its theoretical maximum density, which is what gives the final product its exceptional mechanical strength and hardness.

The Crystalline Transformation

As zirconia is heated, it undergoes a critical phase change. Between 1100°C and 1200°C, it transforms from its monoclinic crystalline state to a much stronger tetragonal state.

The final sintering at a higher temperature (e.g., 1500°C) locks in this durable tetragonal structure, ensuring the material's long-term stability.

The Importance of a Slow Ramp Rate

Achieving the peak temperature is only part of the equation. The rate at which the furnace heats, known as the ramp rate, is equally important.

Most manufacturers recommend a slow heat rise between 4°C and 10°C per minute. This gradual increase prevents thermal shock and ensures the entire zirconia structure heats uniformly, which is essential for avoiding internal stresses and potential cracking.

Common Pitfalls and Why They Matter

Precise temperature regulation is not optional; it is a fundamental requirement for quality. Deviating from the recommended protocol introduces significant risks that can ruin the final product.

The Danger of Sintering Too Hot

Exceeding the manufacturer's recommended temperature can be destructive. Overheating may cause uncontrolled grain growth, which leads to several negative consequences:

- Reduced Stability: The material can become more prone to degradation over time.

- Cracking: Internal stresses can build, leading to fractures.

- Lowered Translucency: For aesthetic applications, particularly in dentistry, overheating can make the zirconia appear opaque and lifeless.

The Problem with Sintering Too Low

Failing to reach the target temperature results in incomplete sintering. This leaves the material porous and weak, as the particles have not fully fused.

An under-fired zirconia part will lack the necessary hardness and strength for its intended application and is highly susceptible to failure.

Why Manufacturer Guidelines Are Absolute

Different zirconia formulations (e.g., high-strength vs. high-translucency) have unique chemical compositions and particle sizes. These variations require specific and unique firing schedules.

Therefore, the manufacturer's instructions for a particular zirconia product should always be treated as the definitive guide.

Making the Right Choice for Your Goal

Your approach to sintering should always align with the specific material you are using and your desired outcome.

- If your primary focus is maximum strength: Strictly follow the manufacturer's recommended peak temperature and hold time to ensure you achieve the highest possible density.

- If your primary focus is aesthetics and translucency: Be extremely careful not to exceed the recommended temperature, as overheating is a primary cause of reduced translucency.

- If you are working with a new material: Always adhere strictly to the datasheet and consider a test run before processing a final, critical component.

Ultimately, precise temperature control is the key to unlocking the full potential of your zirconia's strength and aesthetics.

Summary Table:

| Key Parameter | Typical Range | Importance |

|---|---|---|

| Sintering Temperature | 1400°C - 1600°C (2552°F - 2912°F) | Fuses particles for maximum density and strength. |

| Ramp Rate | 4°C - 10°C per minute | Prevents thermal shock and ensures uniform heating. |

| Goal | ~99% Theoretical Density | Achieves final product's hardness and stability. |

Achieve perfect sintering results with a furnace you can trust.

Precise temperature control is non-negotiable for unlocking zirconia's full potential. KINTEK's advanced laboratory furnaces are engineered to deliver the exact heating profiles and uniform temperatures required for consistent, high-quality results—whether your priority is ultimate strength or optimal aesthetics.

Contact our experts today to find the ideal sintering solution for your lab's specific materials and applications.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How can a porcelain furnace be calibrated using a visual indicator approach? Master Material-Specific Accuracy

- What is the temperature of sintering zirconia? Mastering the Protocol for Perfect Dental Restorations

- What is the firing temperature of dental porcelain? A Guide to Classes from Ultra-Low to High-Fusing

- Can ceramic crowns be repaired? A Dentist's Guide to Assessing the Damage

- What is dental ceramics composed of? A Guide to Glass, Crystal, and Clinical Applications

- What are the components of dental porcelain? A Guide to Engineered Strength and Beauty

- How long should a porcelain ceramic crown last? Maximize Your Investment with Proper Care

- Which is cheaper porcelain or ceramic crown? A Practical Guide to Dental Crown Costs & Materials