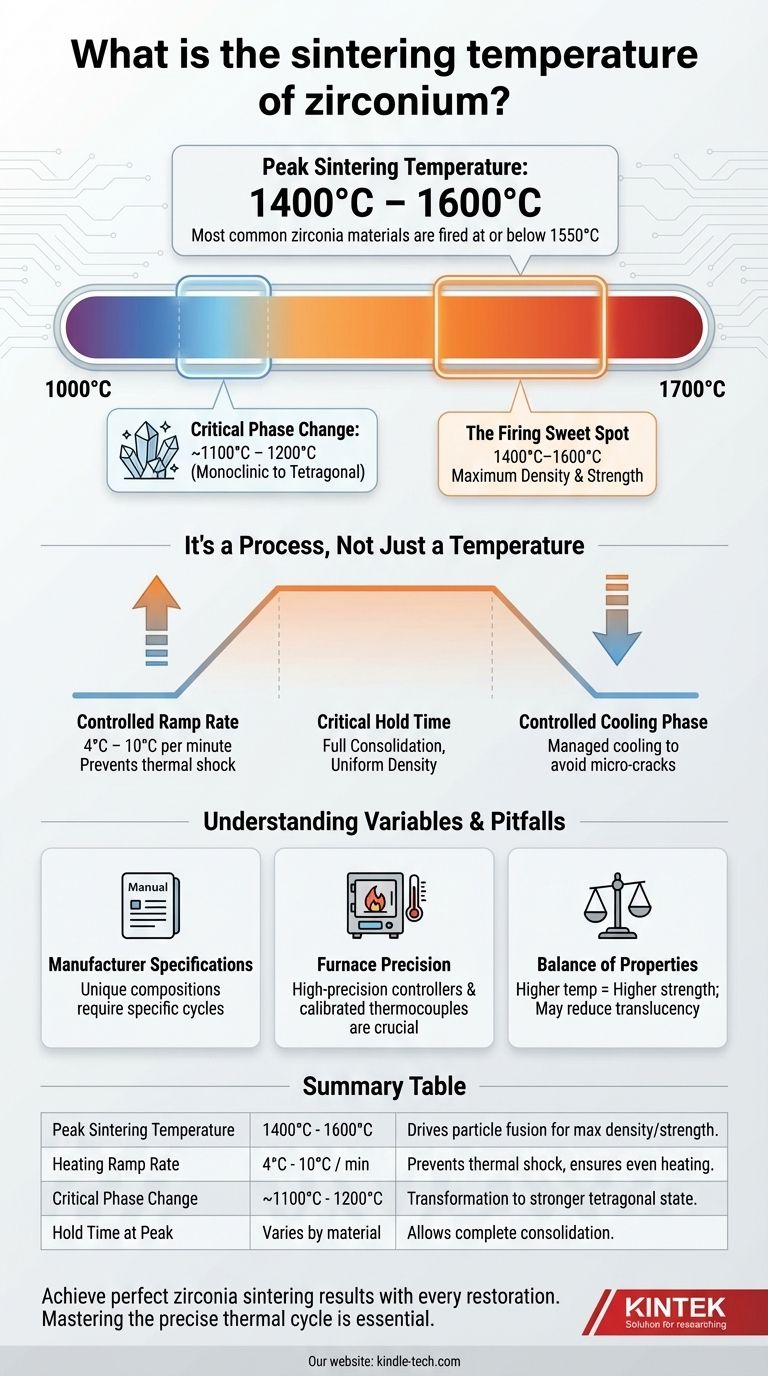

In practice, dental zirconia is sintered at a peak temperature between 1400°C and 1600°C. While the material begins to transform its crystal structure at a lower temperature, this higher range is necessary to achieve the maximum density, hardness, and strength required for durable dental restorations. Most common zirconia materials are fired at or below 1550°C.

The key to successful zirconia sintering is not a single temperature, but a precisely controlled heating and cooling cycle. The final strength and quality of the restoration depend just as much on the rate of temperature change and the hold time as they do on the peak temperature itself.

Why High-Temperature Sintering is Critical

Sintering is a thermal process that converts a porous, "green state" material into a dense, solid object. For zirconia, this process is fundamental to its performance as a restorative material.

The Goal: Achieving Maximum Density

The primary objective of sintering is to eliminate the pores between the zirconia particles. Firing at temperatures near 1500°C allows the particles to fuse, achieving a density close to 99% of the theoretical maximum. This high density is directly correlated with the material's final strength and hardness.

The Crystalline Transformation

Zirconia undergoes a critical phase transformation as it is heated. It changes from its initial monoclinic crystal state to a much stronger tetragonal state at approximately 1100°C to 1200°C. Firing well above this transformation point ensures the process is completed thoroughly.

The Firing "Sweet Spot"

The typical range of 1400°C to 1600°C is the "sweet spot" that provides enough thermal energy to drive densification without causing grain growth that could compromise the material's properties.

It's a Process, Not Just a Temperature

Achieving the right peak temperature is only one part of a successful sintering cycle. The entire thermal profile is engineered to produce the best possible result.

The Importance of Ramp Rate

The furnace must heat up slowly and with extreme control. A slow heat rise, often between 4°C and 10°C per minute, prevents thermal shock and ensures the entire restoration heats evenly. This is especially critical as the material passes the 900°C mark.

The Critical "Hold Time"

Once the peak temperature is reached, it is held constant for a specific duration. This "hold time" or "soak time" allows the material to fully consolidate and the microscopic fusion of particles to complete, ensuring uniform density throughout the restoration.

The Controlled Cooling Phase

Just as important as heating, the cooling rate must be carefully managed, especially as the temperature descends back below 900°C. Cooling too quickly can induce internal stresses, leading to micro-cracks and a significantly weaker final product.

Understanding the Variables and Pitfalls

While the general principles are consistent, several factors can influence the outcome. Ignoring them can lead to costly failures.

Manufacturer Specifications Are Key

Different zirconia formulations (e.g., high-strength vs. high-translucency) have unique compositions. Therefore, manufacturers provide specific temperature and cycle recommendations for their materials. Deviating from these can lead to suboptimal results.

The Need for Furnace Precision

The process demands exceptional accuracy. Sintering furnaces must be equipped with high-precision temperature controllers and calibrated thermocouples to ensure the programmed cycle is executed perfectly. An uncalibrated furnace that is off by even a small margin can ruin an entire batch.

The Balance of Properties

Slight adjustments in the sintering temperature can be used to influence the final properties. For example, higher temperatures may slightly increase strength but can sometimes reduce translucency. This trade-off must be managed based on the clinical requirements of the restoration.

Making the Right Choice for Your Goal

To ensure reliable and high-quality results, tailor your approach to your primary objective.

- If your primary focus is maximum strength and density: You will need to sinter at the higher end of the manufacturer's recommended range, typically between 1500°C and 1550°C.

- If your primary focus is consistency and avoiding failures: Prioritize a slow, controlled heating and cooling cycle and verify that your furnace's temperature is accurately calibrated.

- If you are working with a new zirconia material: Always begin by following the manufacturer's recommended firing schedule without any modification.

Ultimately, mastering zirconia sintering comes from understanding that the entire, carefully controlled cycle is what produces a successful restoration.

Summary Table:

| Key Sintering Parameter | Typical Range / Value | Importance |

|---|---|---|

| Peak Sintering Temperature | 1400°C - 1600°C | Drives particle fusion for maximum density and strength. |

| Heating Ramp Rate | 4°C - 10°C per minute | Prevents thermal shock and ensures even heating. |

| Critical Phase Change | ~1100°C - 1200°C | Transformation from monoclinic to stronger tetragonal crystal state. |

| Hold Time at Peak | Varies by material | Allows for complete consolidation and uniform density. |

Achieve perfect zirconia sintering results with every restoration.

Mastering the precise thermal cycle is essential for producing strong, reliable dental prosthetics. KINTEK specializes in high-precision laboratory sintering furnaces and consumables, designed specifically for the demanding needs of dental labs. Our equipment delivers the accurate temperature control and uniform heating required to follow manufacturer specifications exactly, ensuring consistent, high-quality outcomes.

Let us help you optimize your sintering process. Contact our experts today to find the perfect furnace solution for your lab.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What makes zirconia translucent? The Science Behind Modern Dental Aesthetics

- What is the sintering time for zirconia? A Guide to Precise Firing for Optimal Results

- What are the white spots on zirconia after sintering? A Guide to Diagnosing and Preventing Defects

- What is the temperature of sintering zirconia? Mastering the Protocol for Perfect Dental Restorations

- What is a dental oven? The Precision Furnace for Creating Strong, Aesthetic Dental Restorations