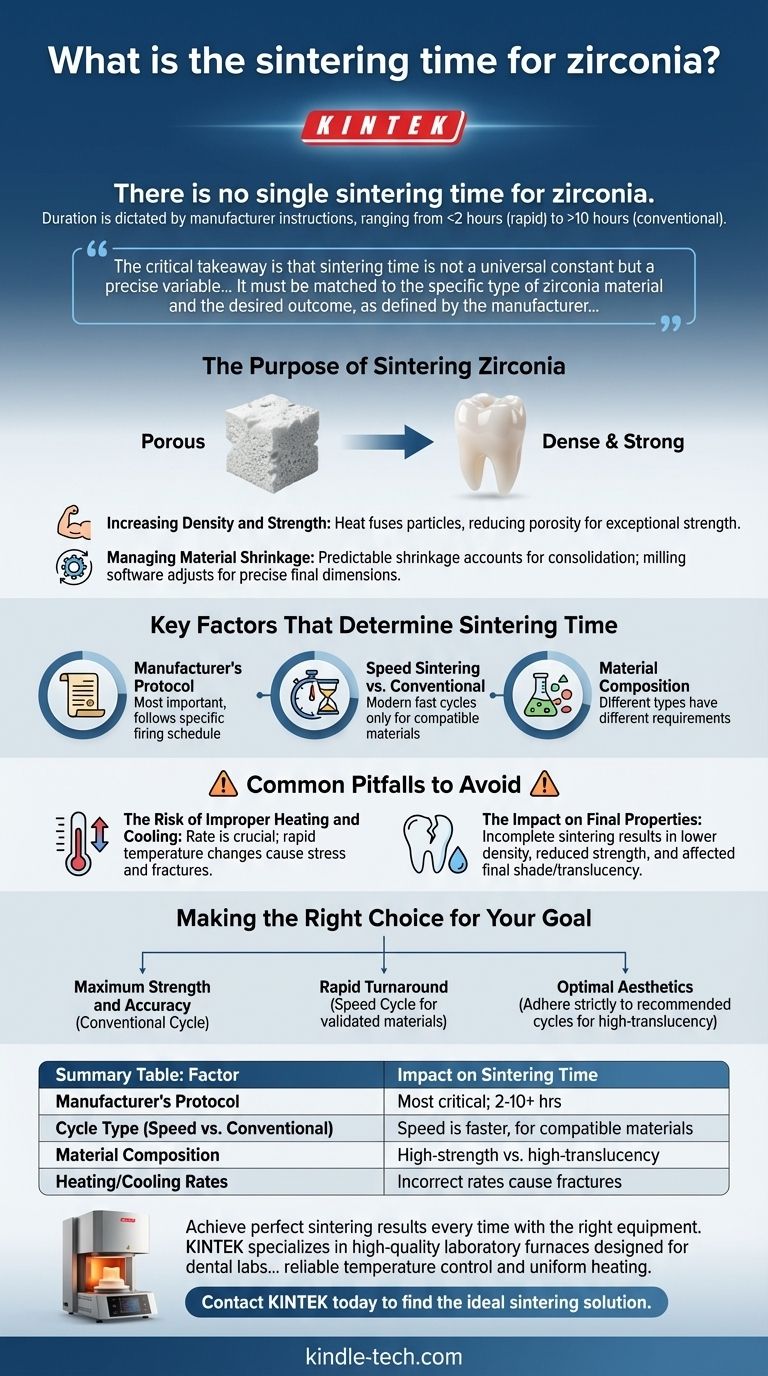

There is no single sintering time for zirconia. The correct duration is dictated entirely by the specific zirconia manufacturer's instructions and can range from under two hours for rapid cycles to over ten hours for conventional methods.

The critical takeaway is that sintering time is not a universal constant but a precise variable in a controlled process. It must be matched to the specific type of zirconia material and the desired outcome, as defined by the manufacturer, to ensure the final product has the required strength, density, and aesthetic properties.

The Purpose of Sintering Zirconia

Sintering is the critical step that transforms a porous, chalk-like zirconia structure into a dense, high-strength ceramic. This process fundamentally changes the material's properties.

Increasing Density and Strength

The primary goal of sintering is to reduce porosity. Heat fuses the individual zirconia particles together, eliminating the voids between them and creating a solid, consolidated mass.

This densification process is directly responsible for the material's exceptional mechanical strength and fracture resistance.

Managing Material Shrinkage

During sintering, zirconia undergoes significant and predictable shrinkage. This is a natural consequence of the particles consolidating and the pores being eliminated.

Milling software accounts for this shrinkage by enlarging the pre-sintered design. A correctly executed sintering cycle ensures the final product shrinks to the precise dimensions intended.

Key Factors That Determine Sintering Time

The ideal sintering time is a function of several interconnected variables. Deviating from the recommended protocol for any of these factors can compromise the final result.

The Manufacturer's Protocol

This is the most important factor. Each brand and type of zirconia is engineered with a specific firing schedule, including heating rates, hold times, and cooling rates. Always follow the manufacturer’s instructions.

These protocols are validated to produce the advertised physical and aesthetic properties of that specific material.

Speed Sintering vs. Conventional Sintering

Many modern furnaces offer "speed" or "fast" sintering cycles that can be completed in a fraction of the time of traditional cycles.

However, these rapid cycles are only compatible with specific zirconia materials designed for them. Using a speed cycle on a conventional zirconia disc can lead to thermal shock, incomplete sintering, and a weakened final product.

Material Composition

Different types of zirconia have different sintering requirements. For example, a high-strength, opaque zirconia used for a bridge framework may have a different cycle than a highly translucent, aesthetic zirconia used for an anterior crown.

Common Pitfalls to Avoid

Understanding the trade-offs between speed and quality is essential for achieving predictable, high-quality results. Rushing or mismatching the process invites failure.

The Risk of Improper Heating and Cooling

The rate at which the furnace heats up and cools down is just as important as the final temperature and hold time.

Heating too quickly can cause stress and fractures within the material. Cooling too rapidly can introduce internal tension, making the final restoration brittle and prone to failure.

The Impact on Final Properties

An incomplete or rushed sintering process results in a product with lower density and reduced strength. The material will not achieve its full potential, making it more susceptible to chipping or breaking under stress.

Furthermore, the final shade and translucency can be negatively affected if the cycle is not executed precisely as the manufacturer intended.

Making the Right Choice for Your Goal

Selecting the correct sintering cycle is about aligning the process with your clinical or production objective.

- If your primary focus is maximum strength and accuracy: Use the conventional, longer sintering cycle specified by the zirconia manufacturer.

- If your primary focus is rapid turnaround: Use only zirconia materials specifically validated for speed sintering, and follow that unique protocol without modification.

- If your primary focus is optimal aesthetics: Adhere strictly to the recommended cycles for high-translucency materials, as their optical properties are highly sensitive to the firing schedule.

Ultimately, mastering the sintering process comes from treating the manufacturer's instructions as your most critical guide.

Summary Table:

| Factor | Impact on Sintering Time |

|---|---|

| Manufacturer's Protocol | Most critical factor; times vary from 2 to 10+ hours. |

| Cycle Type (Speed vs. Conventional) | Speed cycles are faster but only for compatible materials. |

| Material Composition | High-strength vs. high-translucency zirconia have different requirements. |

| Heating/Cooling Rates | Incorrect rates can cause fractures and require process adjustment. |

Achieve perfect sintering results every time with the right equipment.

Choosing the correct sintering cycle is only half the battle; precise and consistent furnace performance is essential for ensuring the final zirconia restoration meets its strength and aesthetic potential.

KINTEK specializes in high-quality laboratory furnaces designed for the exacting demands of dental labs. Our sintering furnaces offer the reliable temperature control and uniform heating necessary to faithfully execute manufacturer protocols, giving you confidence in the quality of your final product.

Ready to enhance your lab's capabilities and ensure predictable, high-quality results?

Contact KINTEK today to find the ideal sintering solution for your laboratory's needs.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is one of the newest applications for dental ceramics? Monolithic Zirconia for Full-Arch Bridges

- What is a dental oven? The Precision Furnace for Creating Strong, Aesthetic Dental Restorations

- What is the price of zirconia sintering furnace? Invest in Precision, Not Just a Price Tag

- What is the effect of zirconia sintering temperature? Master the Key to Strength and Stability

- What is the temperature of sintering zirconia? Mastering the Protocol for Perfect Dental Restorations