From a purely mechanical standpoint, the strongest dental ceramic available today is zirconia, specifically 3Y-TZP (3 mol% yttria-stabilized tetragonal zirconia polycrystal). With a flexural strength often exceeding 1,000 MPa, it significantly surpasses all other ceramic options in its resistance to fracture.

The search for the "strongest" ceramic often masks the real clinical question: which material provides the optimal balance of strength, esthetics, and longevity for a specific case? The strongest material is not always the most appropriate choice.

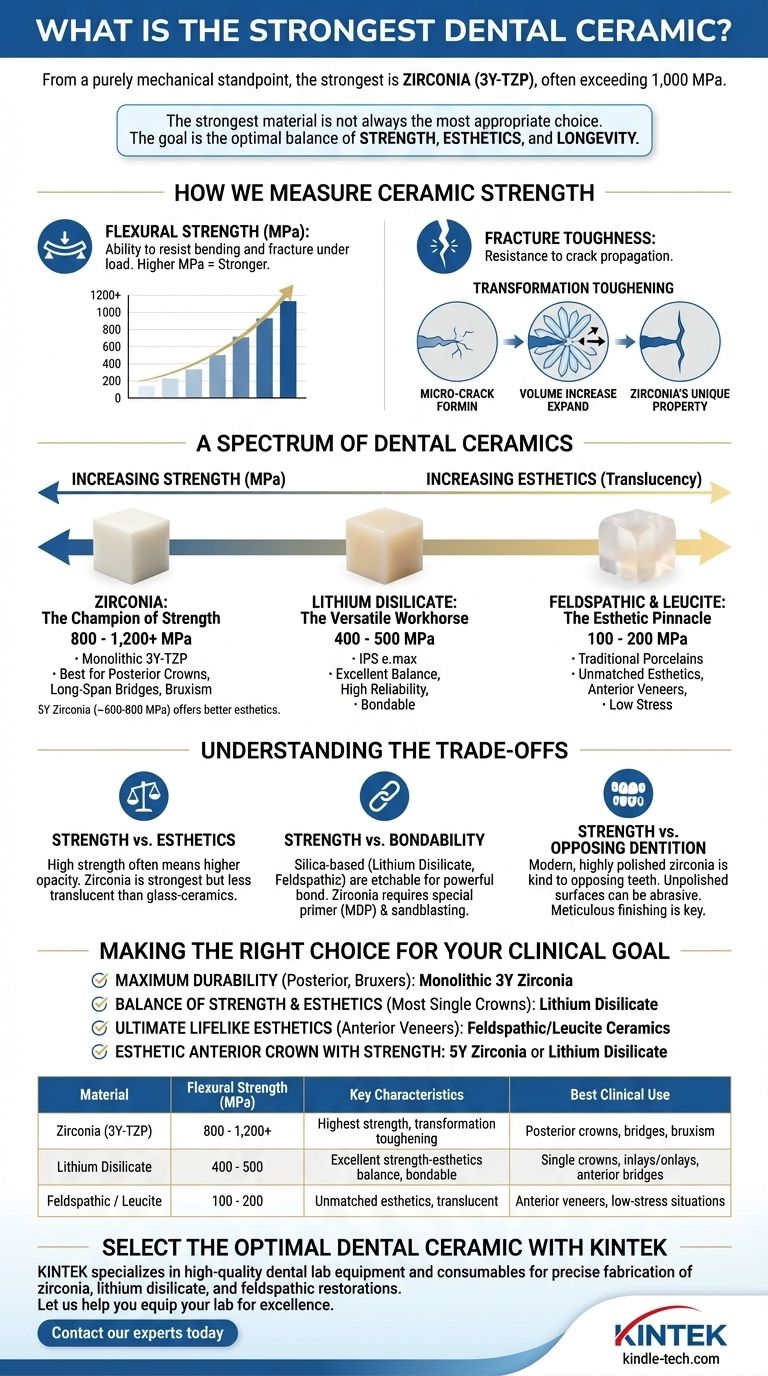

How We Measure Ceramic Strength

To understand why zirconia is the strongest, we must first define the key metrics used to evaluate dental materials. These figures provide an objective basis for comparison.

Flexural Strength (MPa)

Flexural strength, measured in megapascals (MPa), is the most common metric. It quantifies a material's ability to resist bending and fracture under a load.

A higher MPa value indicates a stronger material that is less likely to break. This is a critical factor for restorations in high-stress areas like the posterior of the mouth.

Fracture Toughness

Fracture toughness measures a material's resistance to the propagation of a crack. This is arguably more clinically relevant than flexural strength.

Zirconia exhibits a unique property called transformation toughening. When a micro-crack begins to form, the crystal structure around the crack tip changes, expanding in volume. This expansion effectively squeezes the crack shut, halting its progression and making the material exceptionally durable.

A Spectrum of Dental Ceramics

Dental ceramics exist on a spectrum, trading strength for esthetics. Understanding where each material falls on this spectrum is key to proper selection.

Zirconia: The Champion of Strength

With a flexural strength ranging from 800 to over 1,200 MPa, monolithic zirconia is the undisputed leader in durability. It is the material of choice for posterior crowns, long-span bridges, and cases involving patients who grind their teeth (bruxism).

Newer formulations, like 5Y zirconia (often called "esthetic" or "anterior" zirconia), sacrifice some strength (dropping to ~600-800 MPa) to gain significantly more translucency, making them suitable for anterior restorations.

Lithium Disilicate: The Versatile Workhorse

Lithium disilicate (e.g., IPS e.max) offers an exceptional balance of properties. Its flexural strength is typically in the 400-500 MPa range, which is more than sufficient for single crowns, inlays, onlays, and even 3-unit anterior bridges.

Its primary advantage is its combination of high strength with excellent optical properties and the ability to be adhesively bonded to tooth structure with very high reliability.

Feldspathic & Leucite-Reinforced Ceramics: The Esthetic Pinnacle

These are the traditional porcelains, known for their unmatched ability to mimic the translucency, opalescence, and fluorescence of natural enamel.

However, their beauty comes at the cost of strength, with flexural strengths typically between 100 and 200 MPa. This limits their use primarily to anterior veneers, where aesthetics are paramount and functional stresses are low.

Understanding the Trade-offs: Why Strongest Isn't Always Best

Choosing a material based on a single property is a clinical error. The decision requires a holistic assessment of the trade-offs involved.

Strength vs. Esthetics

This is the central compromise in dental ceramics. The high crystalline content that gives zirconia its immense strength also makes it more opaque than glass-ceramics like lithium disilicate. While newer zirconias are improving, they still do not fully replicate the vitality of silica-based ceramics.

Strength vs. Bondability

Silica-based ceramics (lithium disilicate, feldspathic) can be etched with hydrofluoric acid, creating a micro-retentive surface that enables a powerful chemical bond with resin cements.

Zirconia, a non-silica-based oxide ceramic, cannot be etched in this way. It requires a different protocol involving sandblasting and a special chemical primer (MDP) to achieve a reliable bond, which may be less predictable for some clinicians.

Strength vs. Opposing Dentition

Early formulations of zirconia gained a reputation for being abrasive to the opposing natural teeth. Modern, highly polished zirconia has been shown to be exceptionally kind to the opposing dentition, often causing less wear than older ceramic types.

However, this is entirely dependent on proper finishing and polishing. An unpolished or adjusted zirconia surface can be very abrasive, highlighting the importance of meticulous clinical technique.

Making the Right Choice for Your Clinical Goal

Your material selection should be driven by the primary objective of the restoration.

- If your primary focus is maximum durability for posterior teeth or bruxers: Monolithic 3Y zirconia is the most predictable choice.

- If your primary focus is a balance of high strength and excellent esthetics: Lithium disilicate is the gold standard for most single-unit crowns, anterior or posterior.

- If your primary focus is the ultimate, most lifelike esthetics for anterior veneers: Feldspathic or leucite-reinforced ceramics remain the superior option.

- If your primary focus is an esthetic anterior crown that requires higher strength: A 5Y "esthetic" zirconia or a lithium disilicate crown are your best options.

By moving beyond the simple question of "what is strongest," you can confidently select the ideal material to achieve a durable, beautiful, and predictable clinical outcome.

Summary Table:

| Material | Flexural Strength (MPa) | Key Characteristics | Best Clinical Use |

|---|---|---|---|

| Zirconia (3Y-TZP) | 800 - 1,200+ | Highest strength, transformation toughening | Posterior crowns, bridges, bruxism cases |

| Lithium Disilicate (e.g., IPS e.max) | 400 - 500 | Excellent strength-esthetics balance, bondable | Single crowns, inlays/onlays, anterior bridges |

| Feldspathic / Leucite-Reinforced | 100 - 200 | Unmatched esthetics, translucent | Anterior veneers, low-stress situations |

Select the Optimal Dental Ceramic with KINTEK

Choosing the right dental ceramic is critical for clinical success. The balance between strength, esthetics, and bondability is unique to every case. KINTEK specializes in providing high-quality dental lab equipment and consumables that support the precise fabrication of zirconia, lithium disilicate, and feldspathic restorations.

Our solutions help dental laboratories achieve consistent, high-quality results, ensuring your restorations meet the exacting demands of durability and beauty. Let us help you equip your lab for excellence.

Contact our experts today to discuss how KINTEK can support your specific laboratory needs and enhance your restorative outcomes.

Visual Guide

Related Products

- Custom-Made Alumina Zirconia Special-Shaped Ceramic Plates for Engineering Advanced Fine Ceramics Processing

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

- High Temperature Wear-Resistant Alumina Al2O3 Plate for Engineering Advanced Fine Ceramics

- Laboratory CVD Boron Doped Diamond Materials

- Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

People Also Ask

- What is the main disadvantage of dental ceramics? Balancing Aesthetics with Fracture Risk

- What is zirconia sintering? The Key to Durable, Precision Dental Restorations

- What is the firing temperature of dental porcelain? A Guide to Classes from Ultra-Low to High-Fusing

- How hot does a dental sintering furnace get? Unlock the Key to Perfect Restorations

- Are ceramic teeth expensive? Investing in Natural-Looking, Durable Dental Restorations

- What is an alternative name for a Dental Press Furnace? Understanding the Dental Ceramic Oven

- What is a dental burnout furnace? A Precision Tool for Flawless Dental Restorations

- What is a dental press used for? Creating High-Strength, Aesthetic Dental Restorations