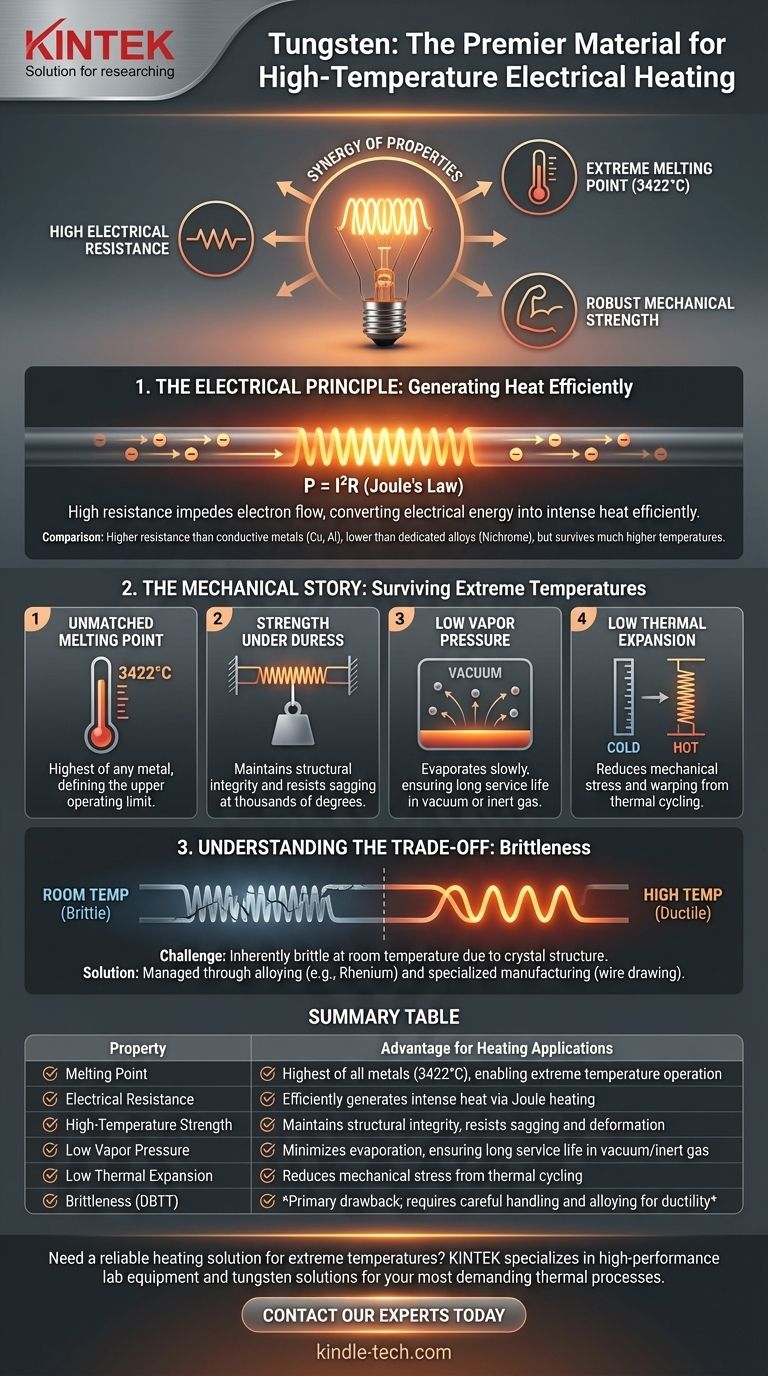

Tungsten's suitability as a material for electrical heating elements is exceptional, stemming from a unique combination of high electrical resistance, an extremely high melting point, and robust mechanical strength at elevated temperatures. This allows it to efficiently generate intense heat via electrical current and withstand the punishing physical stresses of that environment without melting or deforming.

The core reason for tungsten's success is not a single attribute, but the synergy of its properties. Its high resistance creates heat, while its unparalleled melting point, low vapor pressure, and high-temperature strength allow it to survive the very heat it generates.

The Electrical Principle: Generating Heat Efficiently

The primary function of a heating element is to convert electrical energy into thermal energy. Tungsten's electrical properties are fundamental to this process.

The Role of High Electrical Resistance

The basis for electric heating is Joule's First Law, where heat generated (P) is proportional to the resistance (R) and the square of the current (I²), often expressed as P = I²R.

Tungsten possesses a high electrical resistance for a metal. When current is passed through it, this resistance impedes the flow of electrons, causing the wire to heat up efficiently and intensely.

Context for Resistivity

While its resistance is high compared to highly conductive metals like copper or aluminum, it is lower than that of alloys specifically designed for heating, like Nichrome. However, Nichrome cannot survive the extreme temperatures that tungsten can, making tungsten the only choice for certain applications.

The Mechanical Story: Surviving Extreme Temperatures

Generating heat is only half the battle; the material must also survive the extreme conditions it creates. Tungsten's mechanical and physical properties are what make it indispensable for high-temperature applications.

The Unmatched Melting Point

Tungsten has the highest melting point of any metal at 3422°C (6192°F). This is the single most important property, as it defines the upper limit of the operating temperature.

Strength Under Duress

Materials naturally weaken as they get hotter. Tungsten is remarkable for its high tensile strength even at thousands of degrees, allowing it to maintain its structural integrity and resist sagging, stretching, or breaking under its own weight.

Resisting Evaporation (Low Vapor Pressure)

At extreme temperatures, atoms can sublimate, or "boil" off a solid surface. Tungsten has the lowest vapor pressure of all metals, meaning it evaporates incredibly slowly. This ensures a long service life, as the element does not rapidly thin out and fail.

Maintaining Shape (Low Thermal Expansion)

Tungsten exhibits low thermal expansion. As it heats and cools, it expands and contracts minimally, which reduces mechanical stress on the element and its mounting structures, preventing warping or fatigue failure.

Understanding the Trade-offs: The Brittleness Challenge

No material is perfect, and tungsten's primary drawback is mechanical, not thermal or electrical.

The Ductile-to-Brittle Transition

Tungsten has a body-centered cubic (BCC) crystal structure, which makes it inherently brittle at and below room temperature. An un-alloyed tungsten filament can be as fragile as glass before it is heated.

This property is defined by the ductile-to-brittle transition temperature (DBTT). Below this temperature, the material is brittle; above it, it becomes ductile and malleable.

Engineering Around Brittleness

This challenge is managed through sophisticated metallurgical processes. Alloying, often with small amounts of rhenium, can lower the DBTT and improve ductility.

Furthermore, the manufacturing process of drawing tungsten into wire imparts a specific microstructure that enhances its strength and flexibility, making it usable in its final form.

Making the Right Choice for Your Application

Selecting the correct heating material requires matching its properties to the specific operational environment and goals.

- If your primary focus is extreme high temperatures (above 1500°C) in a vacuum or inert gas: Tungsten is the undisputed choice due to its unmatched melting point and low vapor pressure.

- If your primary focus is mid-range heating in the presence of oxygen (e.g., a toaster): An alloy like Nichrome is superior, as it forms a protective oxide layer that prevents burnout, a task tungsten performs poorly.

- If your primary focus is impact resistance and handling at room temperature: A different material or a specially processed tungsten alloy must be used to overcome its inherent brittleness.

Ultimately, tungsten is the definitive material for applications where surviving the highest possible temperatures is the most critical design constraint.

Summary Table:

| Property | Advantage for Heating Applications |

|---|---|

| Melting Point | Highest of all metals (3422°C), enabling extreme temperature operation |

| Electrical Resistance | Efficiently generates intense heat via Joule heating |

| High-Temperature Strength | Maintains structural integrity, resists sagging and deformation |

| Low Vapor Pressure | Minimizes evaporation, ensuring long service life in vacuum/inert gas |

| Low Thermal Expansion | Reduces mechanical stress from thermal cycling |

| Brittleness (DBTT) | Primary drawback; requires careful handling and alloying for ductility |

Need a reliable heating solution for extreme temperatures?

Tungsten heating elements are the definitive choice for applications where surviving temperatures above 1500°C is critical. KINTEK specializes in high-performance lab equipment and consumables, providing robust solutions for your most demanding thermal processes.

Contact our experts today to discuss how tungsten's unparalleled properties can enhance your laboratory's capabilities and ensure long-lasting, efficient performance.

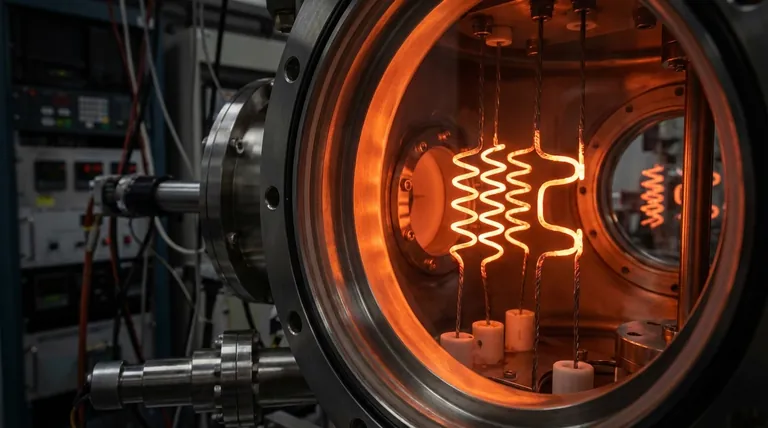

Visual Guide

Related Products

- Thermally Evaporated Tungsten Wire for High Temperature Applications

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- High Temperature Constant Temperature Heating Circulator Water Bath Chiller Circulator for Reaction Bath

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What are the properties of molybdenum heating element? Choose the Right Type for Your Furnace Atmosphere

- What is the design and application of PTC surface heaters? Optimize Direct Contact Heating for Laboratory Precision

- Which material is suitable for use in the heating element? Match the Right Material to Your Application

- How does resistance heating work? Master the Two Core Methods for Efficient Heat

- What are the symptoms of a bad thermocouple? Diagnose a Pilot Light That Won't Stay Lit

- What determines the size of a heating element? Key Factors for Optimal Performance & Lifespan

- Why is tungsten used in furnaces? Unmatched Heat Resistance for Extreme Temperatures

- What is a graphite heater? Achieve Superior Temperature Uniformity and Stability