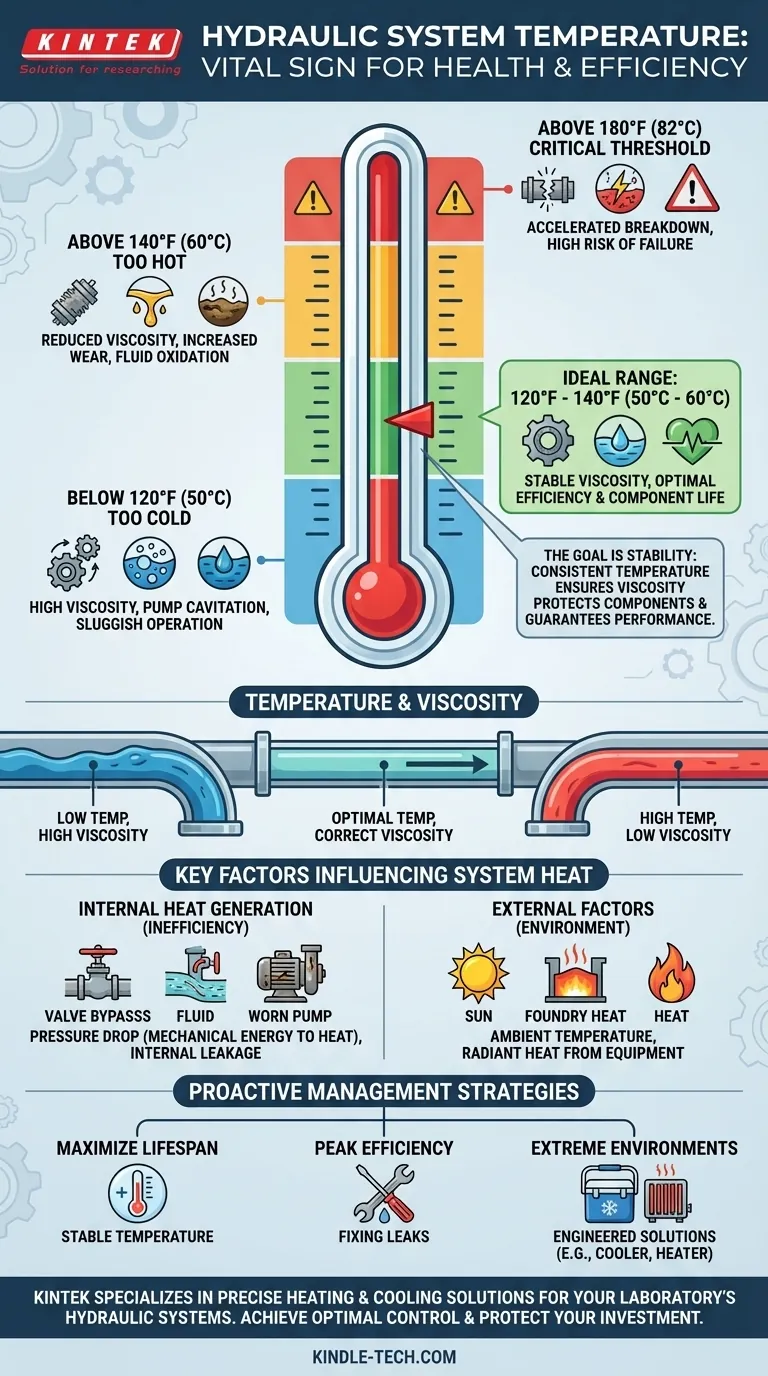

In most industrial applications, the ideal operating temperature for a hydraulic system is between 120°F and 140°F (50°C to 60°C). While systems can function outside this range, exceeding 180°F (82°C) is a critical threshold where fluid degradation accelerates and component damage becomes a significant risk.

The specific temperature of a hydraulic system is less important than its stability. The primary goal is to maintain a consistent temperature within the optimal range to ensure the hydraulic fluid's viscosity remains stable, protecting components and guaranteeing predictable performance.

Why Temperature Is a Critical Health Indicator

A hydraulic system's temperature is a direct indicator of its operational efficiency. Every unit of waste heat is a unit of wasted energy, often generated by inefficiencies within the system itself.

The Central Role of Viscosity

Viscosity is a fluid's resistance to flow. Temperature has the single greatest impact on the viscosity of your hydraulic oil.

The entire system—from the pump to the motors and seals—is designed to operate with the fluid at a specific viscosity. Maintaining the right temperature is fundamentally about maintaining the right viscosity.

The Dangers of High Temperatures

When hydraulic fluid becomes too hot, its viscosity drops, meaning it becomes too thin. This creates a cascade of problems.

Thin fluid cannot maintain an adequate lubricating film between moving parts, leading to increased friction and wear. It can also bypass internal seals in pumps, cylinders, and valves, causing a loss of pressure, efficiency, and control.

Most critically, temperatures above 180°F (82°C) dramatically accelerate fluid oxidation. This chemical breakdown creates sludge and varnish that clogs filters, sticks valves, and causes premature component failure.

The Problems with Low Temperatures

When the system is too cold, the fluid's viscosity increases, meaning it becomes too thick. This condition also strains the system.

Thick, cold fluid is difficult for the pump to draw from the reservoir, which can lead to starvation and cavitation—the formation and collapse of vapor bubbles that can erode internal pump components.

This high viscosity also increases the pressure required to move the fluid through the system, wasting energy and causing sluggish, unresponsive actuator movements until the system warms up.

Key Factors Influencing System Heat

Understanding where the heat comes from is the first step in managing it. Heat in a hydraulic system is generated internally from inefficiency and absorbed externally from the environment.

Internal Heat Generation

The vast majority of heat is generated internally whenever fluid flows from an area of high pressure to low pressure without performing useful work. This pressure drop is a direct conversion of mechanical energy into heat.

Common sources include relief valves bypassing fluid, flow controls, and internal leakage in worn pumps or motors. An efficient system is, by definition, a cooler system.

The Role of the Reservoir

The hydraulic reservoir (or tank) is the system's first line of defense against heat. It provides a large surface area for heat to dissipate into the surrounding air.

A properly sized reservoir allows the fluid enough "dwell time" to cool and for entrained air to escape before being drawn back into the pump.

Environmental and External Factors

The ambient temperature of the operating environment is a major factor. A system operating in a hot foundry will absorb heat, while one in a cold climate will constantly lose it.

Radiant heat from nearby engines or other equipment can also add a significant thermal load to the system.

Making the Right Choice for Your System

Proactive temperature management is not about hitting one perfect number; it's about understanding your operational goals and creating a stable environment for your equipment.

- If your primary focus is maximizing component lifespan: Your goal is stability. Aim to keep the system consistently within the 120-140°F (50-60°C) range to minimize fluid degradation and wear.

- If your primary focus is peak efficiency: Investigate the sources of heat. High temperatures are often a symptom of pressure drops, so finding and fixing internal leaks or inefficient circuit designs will both lower temperatures and reduce energy consumption.

- If your primary focus is operating in extreme environments: You must use engineered solutions. This means installing correctly sized heat exchangers (coolers), tank heaters, and potentially using multi-grade hydraulic fluids designed to maintain viscosity across a wider temperature range.

Ultimately, treating your system's temperature as a vital sign is the key to ensuring its long-term health and reliability.

Summary Table:

| Temperature Range | Condition | Primary Impact |

|---|---|---|

| Below 120°F (50°C) | Too Cold | High viscosity, pump cavitation, sluggish operation |

| 120°F - 140°F (50°C - 60°C) | Ideal Range | Stable viscosity, optimal efficiency & component life |

| Above 140°F (60°C) | Too Hot | Reduced viscosity, increased wear, fluid oxidation |

| Above 180°F (82°C) | Critical | Accelerated fluid breakdown, high risk of component failure |

Is your hydraulic system running too hot or too cold? Unstable temperatures lead to wasted energy, premature wear, and costly downtime. KINTEK specializes in lab equipment and consumables, providing the precise heating and cooling solutions your laboratory's hydraulic systems need to operate reliably and efficiently. Contact us today to discuss how we can help you achieve optimal temperature control and protect your investment. Get in touch via our contact form!

Visual Guide

Related Products

- 100L Chilling Circulator Cooling Water Circulator for Low Temperature Constant Temperature Reaction Bath Water Bath Cooling

- 80L Chilling Circulator Cooling Water Circulator for Water Bath Cooling and Low Temperature Constant Temperature Reaction Bath

- 5L Chilling Circulator Cooling Water Bath Circulator for Low Temperature Constant Temperature Reaction Bath

- 100L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

- 10L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

People Also Ask

- How many tons can a hydraulic press hold? Understanding Safe vs. Maximum Capacity

- How are hydraulic presses so strong? Unlocking Immense Force with Pascal's Law

- Why is a laboratory hydraulic press used for refractory bricks? Achieve Peak Green Body Density and Strength

- How does temperature affect forging? Master Hot, Cold, and Warm Forging for Optimal Results

- How do you prepare KBr pellets for IR? Master the Technique for Clear, Accurate Spectra

- Why is a laboratory hydraulic press used for pelletizing metal oxide powders? Unlock Precise Gas-Sensing Data

- What are the advantages of press forging? Achieve Superior Control for Complex, High-Strength Components

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy