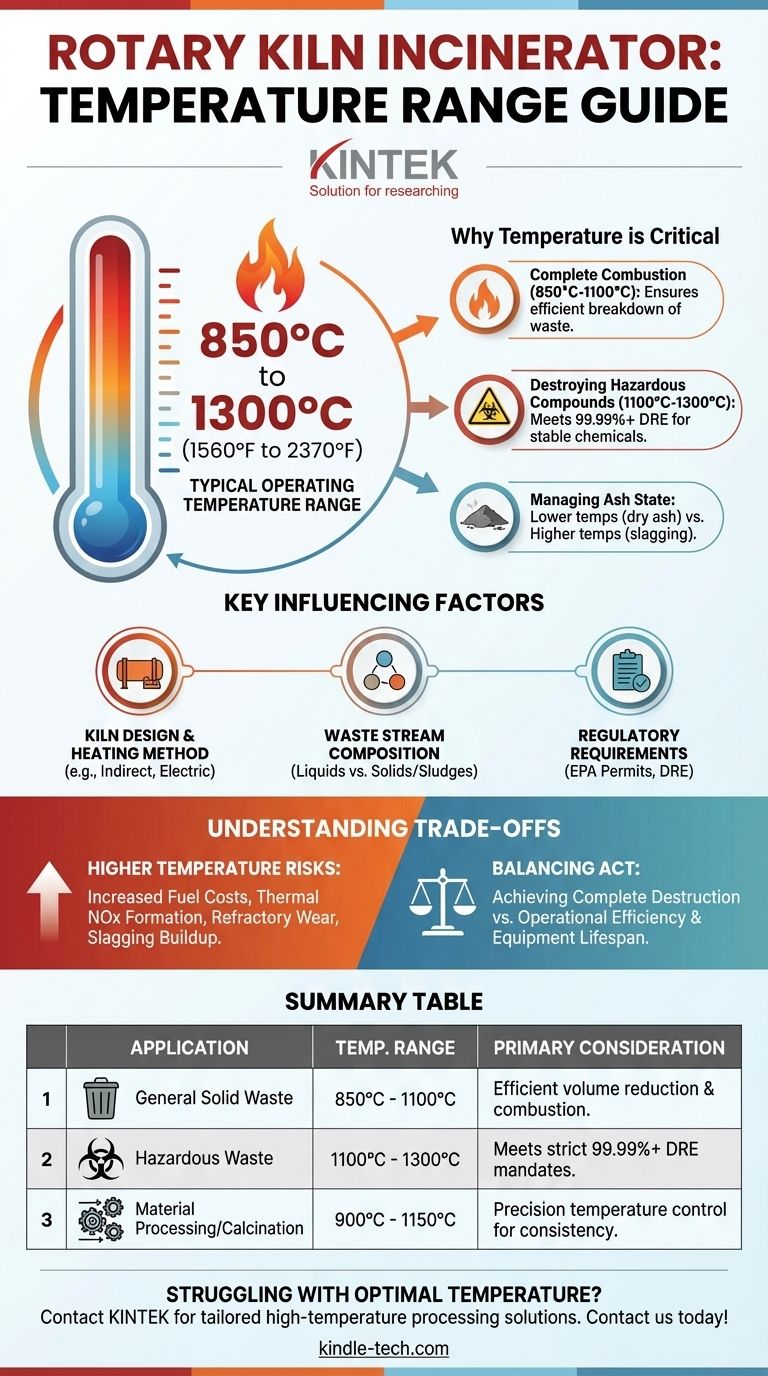

In short, a rotary kiln incinerator typically operates at high temperatures, generally ranging from 850°C to 1300°C (1560°F to 2370°F). The exact temperature depends heavily on the type of waste being processed, the specific design of the kiln (such as direct-fired, indirect, or electric), and the required destruction efficiency for hazardous components.

The specific operating temperature of a rotary kiln is not a fixed value but a critical variable. It is strategically chosen to balance the need for complete waste destruction against the practicalities of energy consumption, regulatory compliance, and equipment lifespan.

Why Temperature is the Critical Parameter

The primary function of a rotary kiln incinerator is to use high thermal energy to destroy waste. Temperature, along with the duration the waste is exposed to that heat (residence time), dictates its effectiveness.

Ensuring Complete Combustion

The fundamental goal is to break down waste materials into simple, stable by-products like carbon dioxide and water vapor, leaving behind an inert ash. Temperatures in the range of 850°C to 1100°C are typically sufficient to ensure complete and efficient combustion of most municipal and industrial wastes.

Destroying Hazardous Compounds

For more hazardous or stable chemical wastes, such as PCBs, dioxins, or certain solvents, higher temperatures are non-negotiable. Regulations often mandate a minimum Destruction and Removal Efficiency (DRE) of 99.99% or higher. Achieving this requires pushing temperatures into the upper range, often exceeding 1100°C and approaching 1300°C, to break the resilient chemical bonds of these pollutants.

Managing the Final Ash State

Temperature directly impacts the physical state of the final ash. Lower temperatures produce a dry, powdery ash. As temperatures increase, the ash can begin to melt and agglomerate, a process known as slagging. In some cases, a fully molten slag is desirable as it encapsulates heavy metals, making the final residue less leachable and safer for disposal.

Factors That Influence the Operating Temperature

The ideal temperature is not universal; it is determined by a combination of waste characteristics and equipment design.

Kiln Design and Heating Method

The way a kiln is heated dramatically affects its temperature profile. Indirect rotary kilns, where the shell is heated externally, can achieve very high furnace temperatures (1200-1300°C) for specialized applications. Electric rotary kilns offer excellent temperature control but may be capped at slightly lower temperatures, often up to 1100°C, making them suitable for processes like calcination where precision is key.

Waste Stream Composition

The nature of the waste is the most significant factor. Liquid organic wastes may burn easily, while contaminated soils or sludges require more energy and higher temperatures to ensure all pollutants are vaporized and destroyed in the gas phase.

Regulatory and Permitting Requirements

Environmental permits are often prescriptive. A facility’s operating permit, issued by a regulatory body like the EPA, will specify a minimum temperature and residence time that must be maintained and continuously monitored to ensure public and environmental safety.

Understanding the Trade-offs

Simply running the kiln at its maximum possible temperature is rarely the correct or most efficient strategy.

Higher Temperature Isn't Always Better

Pushing for excessively high temperatures significantly increases fuel consumption and operational costs. It also promotes the formation of thermal Nitrogen Oxides (NOx), a regulated pollutant that requires additional downstream gas treatment.

The Risk of Premature Slagging

If the temperature exceeds the melting point of the ash, it can form a hard, glass-like slag that coats the kiln's internal refractory walls. This build-up reduces thermal efficiency, can cause severe mechanical damage, and often requires costly shutdowns for manual removal.

Refractory Wear and Tear

The refractory brick lining that protects the kiln's steel shell degrades much faster at higher temperatures. Operating at 1300°C versus 1000°C can dramatically shorten the life of this critical component, leading to more frequent and expensive maintenance.

Making the Right Choice for Your Application

The optimal temperature is a strategic decision based on your primary objective.

- If your primary focus is general solid waste volume reduction: A moderate range of 850°C to 1100°C is typically the most efficient and cost-effective solution.

- If your primary focus is destroying highly stable hazardous waste: You must operate at the higher end of the range, typically 1100°C to 1300°C, to meet regulatory DRE mandates.

- If your primary focus is material processing or calcination: Precision is more important than raw heat, and an indirect or electric kiln operating between 900°C and 1150°C will likely provide the best control.

Ultimately, selecting the correct temperature is a calculated balance between achieving complete destruction, complying with regulations, and maintaining the long-term economic viability of the operation.

Summary Table:

| Key Factor | Typical Temperature Range | Primary Consideration |

|---|---|---|

| General Solid Waste | 850°C - 1100°C | Efficient volume reduction and combustion. |

| Hazardous Waste (PCBs, Dioxins) | 1100°C - 1300°C | Meets strict 99.99%+ destruction efficiency (DRE) mandates. |

| Material Processing/Calcination | 900°C - 1150°C | Precision temperature control for consistent results. |

Struggling to determine the optimal temperature for your waste incineration or material processing? The right thermal profile is critical for efficiency, compliance, and equipment longevity. KINTEK specializes in high-temperature processing equipment, including rotary kilns, and our experts can help you configure a system tailored to your specific waste stream and operational goals. Contact us today via our [#ContactForm] to discuss your application and ensure complete, cost-effective destruction.

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What biomass is used in pyrolysis? Selecting the Optimal Feedstock for Your Goals

- What is the principle of rotary kiln? Mastering Continuous Thermal Processing

- What is the purpose of a calciner? Boost Efficiency in High-Temperature Processing

- What are the different types of reactors in plastic pyrolysis? Choose the Right System for Your Waste

- What are the types of pyrolysis reactors used in industry? Choose the Right Technology for Your Product