In practice, a specific type of indirect rotary kiln may operate with a furnace tube temperature of 1200-1300°C to heat the material inside to just under 1150°C. However, this is just one example. The true temperature range of a rotary kiln is exceptionally broad because it is not a fixed property of the machine, but rather a parameter defined entirely by the process it is designed to perform, spanning from low-temperature drying to high-temperature chemical reactions.

The central takeaway is that a rotary kiln does not have a single "temperature range." Instead, its operating temperature is a highly engineered profile—customized along the length of the kiln—to drive a specific physical or chemical transformation in the material being processed.

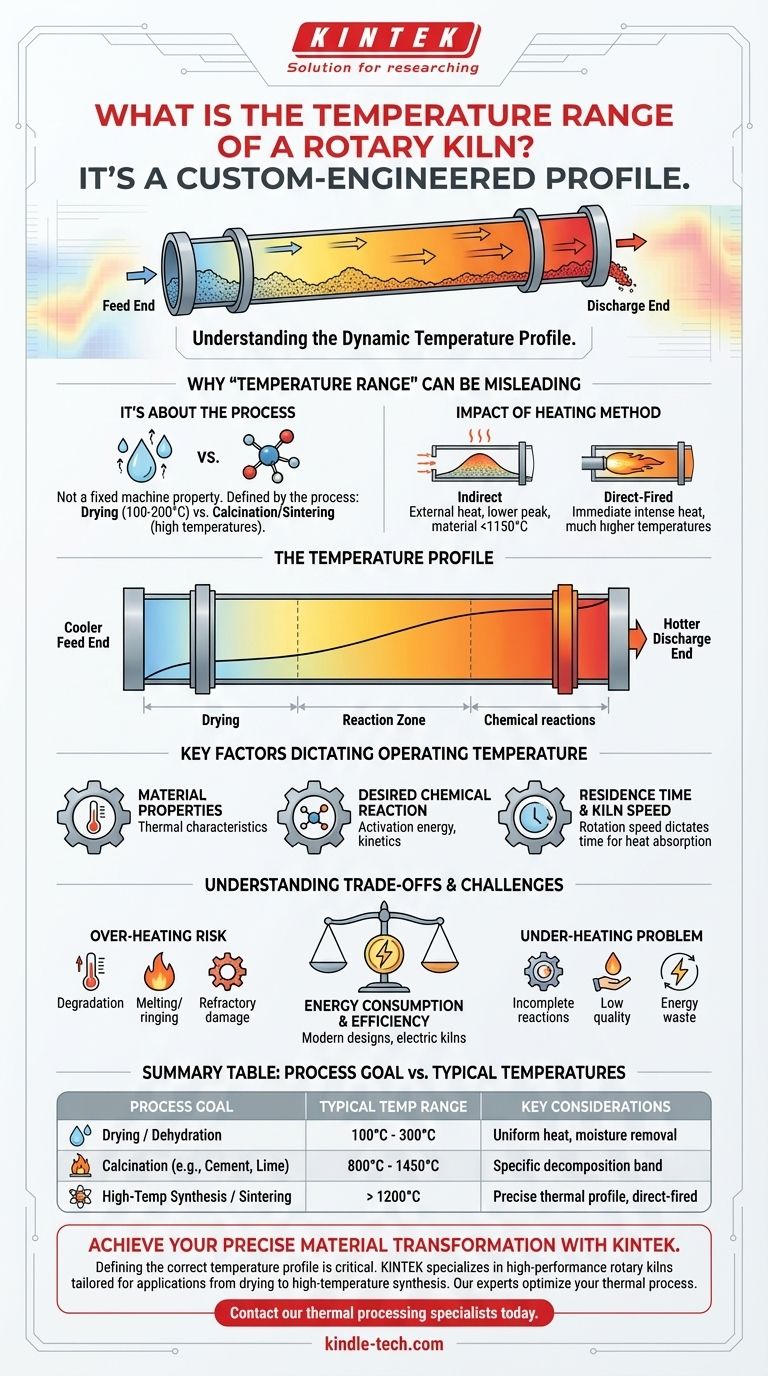

Why "Temperature Range" Can Be Misleading

Thinking of a rotary kiln's temperature as a single number overlooks its fundamental design principle. The temperature is a dynamic variable tailored to the specific task at hand.

It's About the Process, Not the Machine

A rotary kiln's purpose can range from simple drying to complex chemical synthesis. Each process demands a unique thermal profile.

Drying or moisture removal might occur at relatively low temperatures (e.g., 100-200°C), while processes like calcination or sintering require extremely high temperatures to initiate chemical reactions or fuse particles together.

The Impact of Heating Method

The way heat is introduced dramatically affects the operating temperature.

Indirect rotary kilns, where the shell is heated from the outside, often operate with material temperatures below 1150°C. The heat must transfer through the kiln wall, which limits the peak temperature.

Direct-fired kilns, where a flame is introduced directly into the kiln in contact with the material, can achieve much higher temperatures, as the heat transfer is immediate and more intense.

The Importance of the Temperature Profile

A rotary kiln rarely operates at one uniform temperature. It is engineered to create a temperature profile or gradient along its length.

Material enters the cooler end and gradually moves toward the hotter discharge end. This controlled progression ensures that drying, heating, and chemical reactions happen in the correct sequence and for the appropriate duration.

Key Factors That Dictate Operating Temperature

The final operating temperature is a result of several interconnected engineering decisions made to optimize the outcome for a specific material.

Material Properties

The thermal characteristics of the raw material are the primary consideration. The temperature must be high enough to achieve the desired change but low enough to avoid unwanted side effects like melting, decomposition, or damage.

Desired Chemical Reaction

The core of many rotary kiln applications is to drive a chemical reaction. These reactions often have high activation energy, requiring very specific and high bed temperatures for kinetic or thermodynamic reasons.

Residence Time and Kiln Speed

The speed at which the kiln rotates dictates the residence time—how long the material spends inside. A slower rotation increases residence time, allowing the material to absorb more heat at a given temperature. Temperature and kiln speed are adjusted in tandem to achieve the target result.

Understanding the Trade-offs and Challenges

Precise temperature control is critical for stable production and product quality. Deviations from the optimal range can cause significant problems.

The Risk of Over-heating

If the temperature is too high, it can lead to product degradation, the formation of undesirable byproducts, or even melting, which can create blockages ("ringing") inside the kiln. Excessive heat can also damage the kiln's internal refractory lining, leading to costly downtime and repairs.

The Problem of Under-heating

Insufficient temperature results in incomplete reactions and a low-quality or unusable final product. This directly impacts process efficiency, wastes energy, and requires reprocessing of the material.

Energy Consumption and Efficiency

Achieving and maintaining high temperatures is energy-intensive. There is a constant trade-off between the thermal energy needed for the process and the operational cost. Modern designs, such as electric rotary kilns, offer alternatives to fossil fuels to improve efficiency and manage emissions.

How to Determine the Right Temperature for Your Process

The ideal temperature is determined by your material's chemistry and your processing goal. It requires careful analysis, starting with your desired outcome.

- If your primary focus is low-temperature drying or dehydration: Your goal is uniform heat distribution and efficient moisture removal, often well below 300°C.

- If your primary focus is calcination (e.g., for cement or lime): Your target will be a specific, high-temperature band required to initiate and complete the chemical decomposition reaction.

- If your primary focus is high-temperature synthesis or sintering: You will require a specialized kiln, likely direct-fired, capable of creating a precise thermal profile that may exceed 1200°C.

Ultimately, the rotary kiln's temperature is a precisely controlled variable that you define to achieve your desired material transformation.

Summary Table:

| Process Goal | Typical Temperature Range | Key Considerations |

|---|---|---|

| Drying / Dehydration | 100°C - 300°C | Uniform heat distribution, moisture removal |

| Calcination (e.g., Cement, Lime) | 800°C - 1450°C | Specific band for chemical decomposition |

| High-Temp Synthesis / Sintering | > 1200°C | Precise thermal profile, often direct-fired |

Achieve your precise material transformation with a custom thermal solution.

Defining the correct temperature profile is critical for your process efficiency and product quality. KINTEK specializes in high-performance lab equipment, including rotary kilns tailored for applications from drying to high-temperature synthesis. Our experts will help you select the right kiln to optimize your specific thermal process.

Contact our thermal processing specialists today to discuss your application requirements.

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- High Temperature Constant Temperature Heating Circulator Water Bath Chiller Circulator for Reaction Bath

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- Can you regenerate activated charcoal? The Truth About Reusing Spent Carbon Filters

- What role does a high-temperature rotary kiln play in the production of cement clinker? Mastering Sintering Efficiency

- What is a fluidized bed chemical reaction? A Guide to Superior Heat Transfer & Continuous Processing

- How long is the calcination process? Optimize Your Process Time for Maximum Efficiency

- What is the temperature and time of pyrolysis? Control Your Product Output with Precision

- How does catalyst work in pyrolysis? A Guide to Efficient and Selective Fuel Production

- What is the difference between microwave pyrolysis and conventional pyrolysis? Choose the Right Heating Method for Your Process

- What is the temperature of a rotary kiln? It's a Controlled Thermal Journey, Not a Single Number