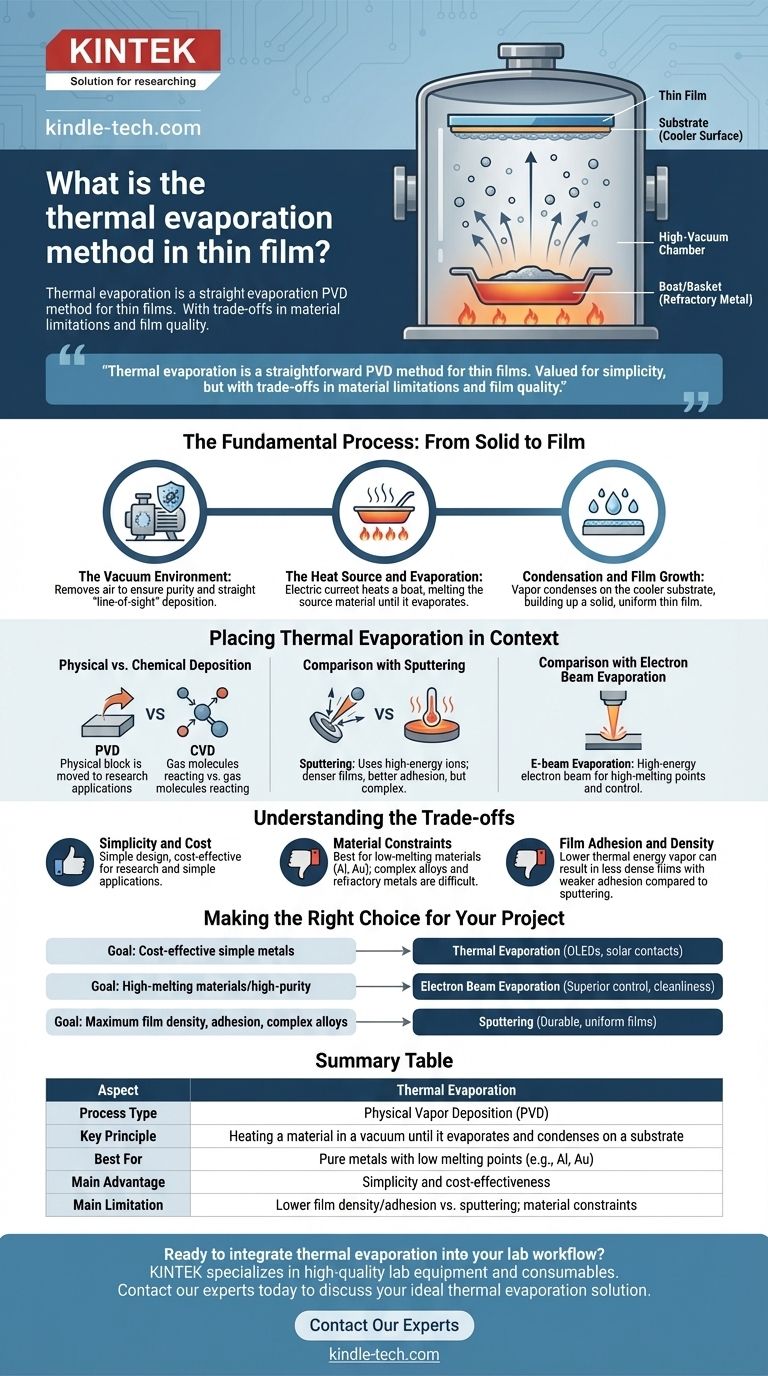

At its core, thermal evaporation is a straightforward method of physical vapor deposition (PVD) used to create thin films. The process involves heating a solid material inside a high-vacuum chamber until it evaporates. This vapor then travels through the vacuum and condenses onto a cooler surface, called a substrate, forming a solid, uniform thin layer.

Thermal evaporation is valued for its simplicity and is a foundational technique for depositing thin layers of pure metals and simple compounds. However, its effectiveness is defined by its trade-offs against more complex methods, particularly concerning material limitations and final film quality.

The Fundamental Process: From Solid to Film

To understand thermal evaporation, it's best to break it down into its three critical stages, all of which occur within a controlled environment.

The Vacuum Environment

The entire process takes place in a high-vacuum chamber. This vacuum is essential because it removes air and other gas particles that could otherwise react with the hot vapor or physically block its path to the substrate.

A clean vacuum ensures the purity of the final film and allows the vaporized material to travel in a straight line, a principle known as "line-of-sight" deposition.

The Heat Source and Evaporation

The source material to be deposited is placed in a container, often called a "boat" or "basket." This container is typically made of a refractory metal like tungsten.

An electric current is passed through this boat, causing it to heat up due to electrical resistance. This heat is transferred to the source material, raising its temperature until it melts and then evaporates into a gas.

Condensation and Film Growth

The vaporized atoms or molecules travel away from the hot source in all directions. When they strike the much cooler substrate (such as a silicon wafer or glass slide) positioned above the source, they rapidly lose their energy.

This causes the material to condense back into a solid state, gradually building up on the substrate atom by atom to form the desired thin film.

Placing Thermal Evaporation in Context

Thermal evaporation is one of many deposition techniques, and choosing the right one depends on your specific goals.

Physical vs. Chemical Deposition

Deposition methods are broadly split into two families. Physical Vapor Deposition (PVD), like thermal evaporation and sputtering, physically transports a material from a source to the substrate without a chemical reaction.

Chemical Vapor Deposition (CVD), in contrast, introduces reactive precursor gases into a chamber that chemically react on the substrate's surface to form the film.

Comparison with Sputtering

Sputtering is another major PVD technique, but it uses kinetic energy instead of thermal energy. In sputtering, high-energy ions from a plasma bombard a target, physically knocking off atoms that then deposit onto the substrate.

Sputtered atoms have much higher energy than evaporated atoms. This generally results in denser films with better adhesion to the substrate, but the equipment is more complex.

Comparison with Electron Beam Evaporation

Electron beam (e-beam) evaporation is a more advanced form of thermal evaporation. Instead of a resistive boat, it uses a high-energy beam of electrons focused on the source material to generate intense, localized heat.

This allows for the deposition of materials with very high melting points and provides greater control over the deposition rate.

Understanding the Trade-offs

The simplicity of thermal evaporation is its greatest strength, but it also brings important limitations you must consider.

The Advantage: Simplicity and Cost

Thermal evaporation systems are relatively simple in design and operation compared to sputtering or CVD systems. This often makes them a more cost-effective choice for both research and certain industrial applications.

The Limitation: Material Constraints

The process works best for materials with relatively low melting and evaporation points, such as pure metals like aluminum, gold, or indium.

Depositing complex alloys is difficult, as the element with the lower boiling point will evaporate first, changing the composition of the source and the film. Refractory metals with very high melting points are also challenging for basic resistive heaters.

The Limitation: Film Adhesion and Density

Because the evaporated atoms arrive at the substrate with low thermal energy, the resulting films can be less dense and have weaker adhesion than those produced by sputtering. This can be a critical factor in applications requiring robust mechanical or electrical performance.

Making the Right Choice for Your Project

Selecting a deposition method requires aligning the technique's capabilities with your project's primary goal.

- If your primary focus is cost-effective deposition of simple metals: Thermal evaporation is an excellent and widely used choice for applications like creating electrical contacts for OLEDs, solar cells, or thin-film transistors.

- If your primary focus is depositing high-melting-point materials or high-purity films: You should consider electron beam evaporation for its superior temperature control and cleanliness.

- If your primary focus is maximum film density, adhesion, or depositing complex alloys: Sputtering is often the superior PVD technique, as the high-energy process creates more durable and uniform films.

Ultimately, choosing the right tool for thin-film deposition means understanding that each method offers a unique balance of simplicity, performance, and cost.

Summary Table:

| Aspect | Thermal Evaporation |

|---|---|

| Process Type | Physical Vapor Deposition (PVD) |

| Key Principle | Heating a material in a vacuum until it evaporates and condenses on a substrate |

| Best For | Pure metals with low melting points (e.g., Al, Au) |

| Main Advantage | Simplicity and cost-effectiveness |

| Main Limitation | Lower film density/adhesion vs. sputtering; material constraints |

Ready to integrate thermal evaporation into your lab workflow?

KINTEK specializes in high-quality lab equipment and consumables for all your thin-film deposition needs. Whether you're researching novel materials or scaling up production, our thermal evaporation systems and expert support can help you achieve precise, reliable results efficiently.

Contact our experts today to discuss the ideal thermal evaporation solution for your laboratory's specific challenges and goals.

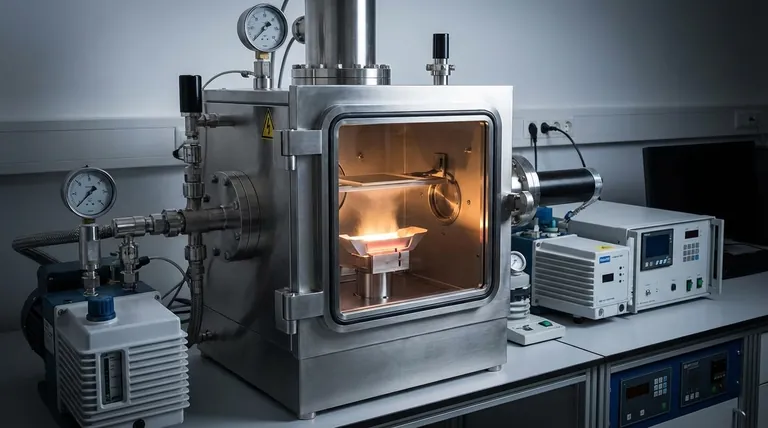

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Electron Beam Evaporation Coating Conductive Boron Nitride Crucible BN Crucible

- Ceramic Evaporation Boat Set Alumina Crucible for Laboratory Use

People Also Ask

- What is the physics of e-beam evaporation? Harnessing Precision Energy for Superior Thin Films

- What is sputtering or thermal evaporation? Choose the Right Thin-Film Deposition Method

- What is the difference between sputtering and e beam evaporation? Choose the Right PVD Method for Your Thin Film

- What is vacuum deposition of metals? A Guide to High-Purity, Durable Metal Coatings

- What is the evaporation technique for nanoparticles? A Guide to High-Purity Synthesis

- What is the flash evaporation method for thin film deposition? Achieve Precise Stoichiometry in Your Films

- What is the thermal deposition method? A Guide to Thin-Film Coating Technology

- What is the difference between e-beam and thermal evaporation? Choose the Right PVD Method for Your Materials