At its core, a diamond coating is a surface engineering technique used to deposit a micro-thin layer of synthetic diamond onto another material. This process imparts the extraordinary properties of diamond—such as extreme hardness, low friction, and high thermal conductivity—onto the surface of a more common and cost-effective substrate, dramatically enhancing its performance in demanding applications.

The fundamental purpose of a diamond coating is not just to protect a surface, but to transform it. It allows engineers to leverage the superior performance of diamond without having to fabricate an entire component from solid, cost-prohibitive diamond.

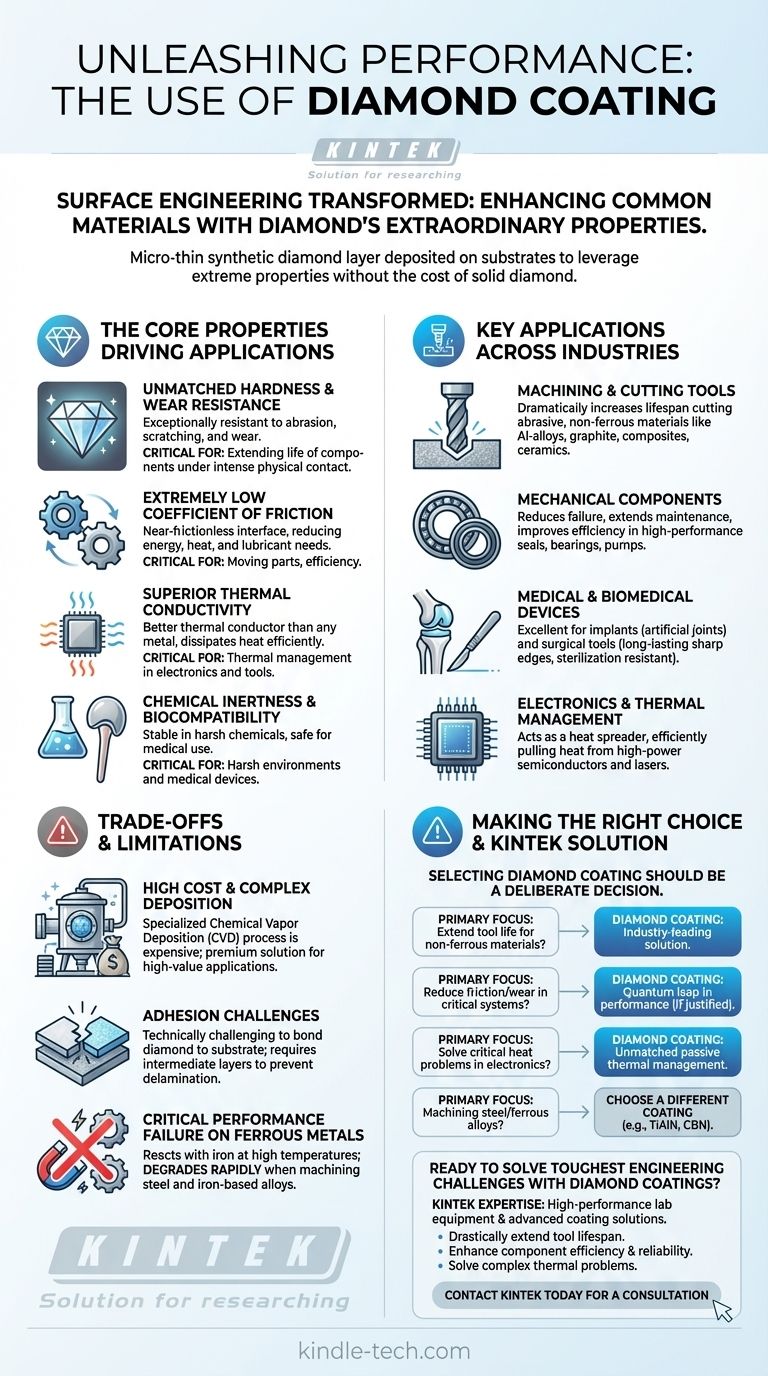

The Core Properties Driving Diamond Coating Applications

The value of a diamond coating stems directly from the unique and extreme physical properties inherent to diamond itself. Understanding these properties is key to understanding its applications.

Unmatched Hardness and Wear Resistance

Diamond is the hardest known material. When applied as a coating, it creates a surface that is exceptionally resistant to abrasion, scratching, and general wear.

This property is critical for extending the life of components that experience intense physical contact, preserving their geometry and function far beyond the limits of uncoated or conventionally coated materials.

Extremely Low Coefficient of Friction

Diamond surfaces are inherently slick, especially against non-ferrous materials. A diamond coating can create a near-frictionless interface between moving parts.

This reduces the energy required to operate machinery, minimizes heat generation from friction, and can even eliminate the need for traditional lubricants in some specialized applications.

Superior Thermal Conductivity

Diamond is a better thermal conductor than any metal, including copper and silver. It can dissipate heat with incredible efficiency.

This makes diamond coatings an elite solution for thermal management, drawing damaging heat away from sensitive components like high-power electronics or the cutting edge of a tool.

Chemical Inertness and Biocompatibility

Diamond is chemically stable and does not react with most acids, bases, or other corrosive agents. It is also biocompatible, meaning it does not provoke an adverse reaction from the human body.

These traits make it suitable for use in harsh chemical environments and for critical medical devices and implants where stability and safety are non-negotiable.

Key Applications Across Industries

These core properties translate into high-value solutions across a range of advanced industries where performance limits are constantly being pushed.

Machining and Cutting Tools

This is the most common application. Coating drills, end mills, and inserts with diamond dramatically increases their lifespan and performance when cutting abrasive, non-ferrous materials.

Materials like high-silicon aluminum alloys, graphite, carbon fiber composites (CFRP), and ceramics are notoriously difficult to machine, but diamond-coated tools can cut them cleanly for extended periods.

Mechanical Components

High-performance seals, bearings, and pump components benefit immensely from diamond's low friction and wear resistance.

In these systems, a diamond coating reduces part failure, extends maintenance intervals, and improves overall efficiency by minimizing energy loss.

Medical and Biomedical Devices

The combination of hardness, low friction, and biocompatibility makes diamond an excellent coating for medical implants, such as artificial joints.

It is also used on surgical tools to provide a lastingly sharp, clean cutting edge that resists corrosion from sterilization processes.

Electronics and Thermal Management

For high-power density semiconductors, lasers, and other electronic components, managing heat is the primary factor limiting performance.

A diamond coating applied as a "heat spreader" can efficiently pull heat away from the active region of a chip, allowing it to run faster and more reliably.

Understanding the Trade-offs and Limitations

While powerful, diamond coating is not a universal solution. Its high performance comes with specific trade-offs and constraints that are critical to understand.

High Cost and Complex Deposition

Applying a diamond coating is a highly specialized process, typically involving Chemical Vapor Deposition (CVD) in a vacuum chamber. This equipment and process are expensive, making diamond coatings a premium solution reserved for high-value applications.

Adhesion Challenges

Successfully bonding the diamond layer to the underlying material (the substrate) is technically challenging. Without a strong bond, the coating can delaminate and fail. This often requires specialized intermediate layers to ensure proper adhesion.

Critical Performance Failure on Ferrous Metals

This is the most significant limitation. Diamond coatings perform poorly when machining steel, stainless steel, and other iron-based alloys at high speeds.

At the high temperatures generated during cutting, the carbon in the diamond chemically reacts with the iron in the steel, causing the coating to rapidly degrade. For these materials, other coatings like TiAlN or CBN are far superior.

Making the Right Choice for Your Goal

Selecting a diamond coating should be a deliberate decision based on a clear performance goal and an understanding of its limitations.

- If your primary focus is extending tool life for cutting non-ferrous materials: Diamond coating is the industry-leading solution for machining aluminum, composites, and graphite.

- If your primary focus is reducing friction and wear in a critical mechanical system: Diamond coatings offer a quantum leap in performance, provided the cost is justified and adhesion is properly engineered.

- If your primary focus is solving a critical heat problem in advanced electronics: Diamond's thermal conductivity is nearly unmatched, making it one of the best available options for passive thermal management.

- If your primary focus is machining steel or other ferrous alloys: You must choose a different coating technology, as a diamond coating will fail quickly and predictably.

By understanding where and why to apply this technology, you can leverage its exceptional properties to solve some of the most demanding engineering challenges.

Summary Table:

| Property | Key Benefit | Primary Application |

|---|---|---|

| Extreme Hardness | Superior wear resistance | Cutting tools, mechanical parts |

| Low Friction | Energy efficiency, reduced wear | Bearings, seals, medical implants |

| High Thermal Conductivity | Superior heat dissipation | Electronics, high-power lasers |

| Chemical Inertness | Corrosion resistance | Harsh chemical environments, medical tools |

Ready to solve your toughest engineering challenges with diamond coatings?

At KINTEK, we specialize in high-performance lab equipment and consumables, including advanced coating solutions. Our expertise can help you leverage the extreme properties of diamond coatings to:

- Drastically extend the lifespan of your cutting tools for non-ferrous materials.

- Enhance the efficiency and reliability of your critical mechanical components.

- Solve complex thermal management problems in your electronic devices.

Let our specialists help you determine if a diamond coating is the right solution for your specific application and material requirements.

Contact KINTEK today for a consultation and see how we can enhance your laboratory's capabilities.

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- Laboratory CVD Boron Doped Diamond Materials

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- CVD Diamond Domes for Industrial and Scientific Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- What is diamond coating film? A Thin Layer of Diamond for Extreme Performance

- How long does diamond coating last? Maximize Lifespan with the Right Coating for Your Application

- What is CVD diamond coating? Grow a Super-Hard, High-Performance Diamond Layer

- Is diamond coating permanent? The Truth About Its Long-Lasting Durability

- What is the process of CVD diamond coating? Grow a Superior, Chemically-Bonded Diamond Layer