At its core, a pressure reactor is a specialized vessel designed to perform chemical reactions or physical processes at pressures higher than the surrounding atmosphere. These devices are essential in science and industry for tasks ranging from sterilizing medical equipment and synthesizing fine chemicals to vulcanizing rubber and conducting advanced pharmaceutical research. By manipulating pressure and temperature, a reactor allows operators to control reaction rates, improve yields, and work with materials under conditions that are otherwise impossible.

The true purpose of a pressure reactor isn't just to contain high pressure; it's to precisely control the reaction environment. Your choice of reactor—its material, design, and safety features—is a critical decision that directly impacts the success, safety, and scalability of your process.

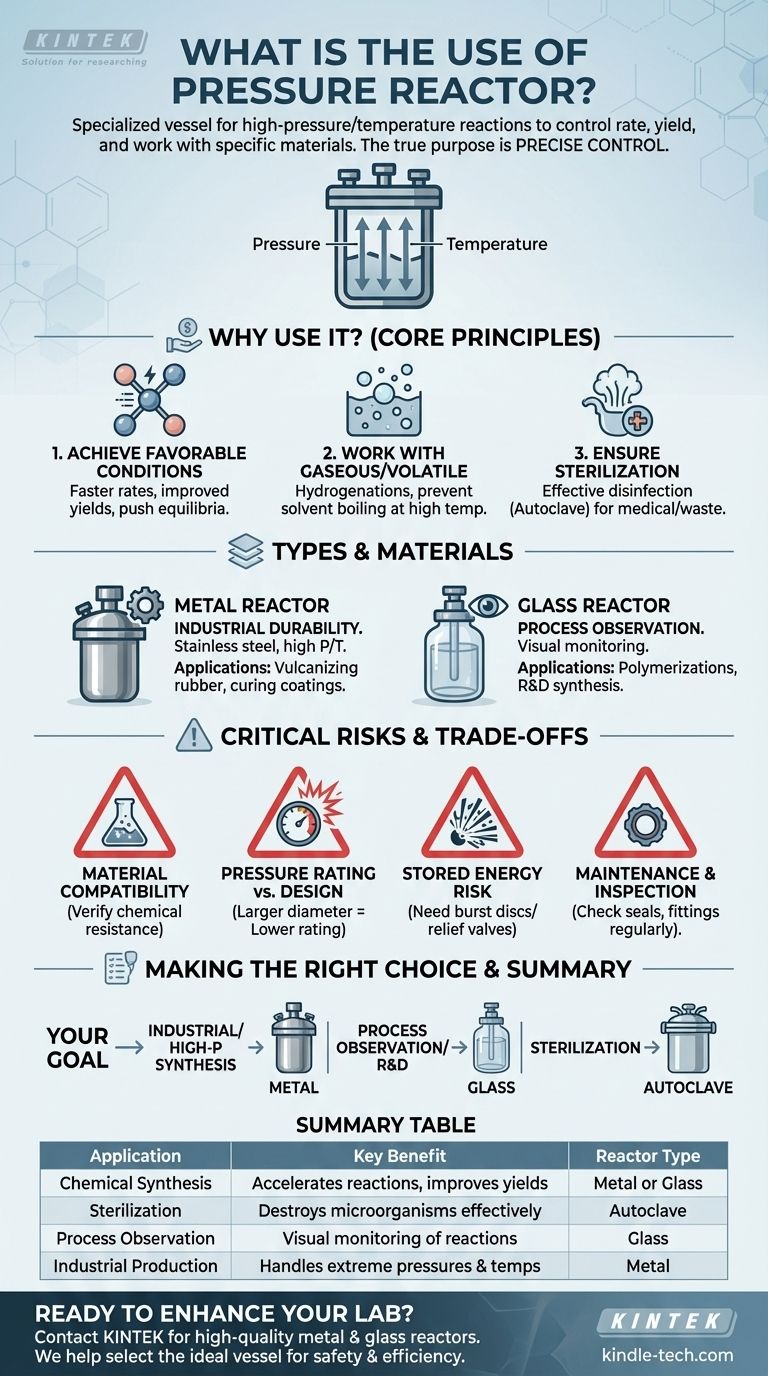

Why Use a Pressure Reactor? The Core Principles

A pressure reactor provides control over the fundamental variables of a chemical or physical process. This control is the primary reason for its use across so many fields.

Achieving Favorable Reaction Conditions

Many chemical reactions are slow or have low yields at atmospheric pressure. Increasing the pressure and temperature inside a reactor can significantly accelerate reaction rates and push chemical equilibria toward the desired products.

This principle is vital for processes like hydrothermal synthesis, where new materials are created in high-temperature aqueous solutions, and for producing fine chemicals where efficiency is paramount.

Working with Gaseous Reagents or Volatile Solvents

Pressure reactors are indispensable when a reaction involves a gas as a key ingredient. For example, in hydrogenations, hydrogen gas is forced to dissolve into a liquid solution to react, a process that requires elevated pressure.

Similarly, if a reaction must be heated above a solvent's normal boiling point, pressurizing the vessel prevents the solvent from boiling away, allowing the process to occur in a liquid phase at a much higher temperature.

Ensuring Sterilization and Disinfection

In the medical and wastewater treatment industries, high pressure combined with high temperature (steam) is a highly effective method for sterilization.

An autoclave, a specific type of pressure reactor, is used to destroy all microorganisms on lab equipment or to disinfect sludge and produce sterile water.

Choosing a Reactor: Material and Design

The two most common families of pressure reactors, metal and glass, offer distinct advantages and are suited for different applications.

Metal Reactors for Industrial Durability

Reactors made from materials like stainless steel are the workhorses of industrial chemistry. They are valued for their strength, durability, and ability to withstand extremely high pressures and temperatures.

This makes them ideal for demanding processes like curing industrial coatings, vulcanizing rubber, and producing advanced composite materials on a large scale.

Glass Reactors for Process Observation

When researchers need to visually monitor a reaction—to observe color changes, phase separation, or crystallization—a glass pressure reactor is the ideal choice.

They are frequently used in research and development for polymerizations, catalytic studies, and synthesis where understanding the process visually is as important as the outcome.

Understanding the Trade-offs and Critical Risks

Selecting and operating a pressure reactor requires a clear understanding of its limitations and the inherent risks involved.

Material vs. Chemical Compatibility

The reactor material must be chemically resistant to the reagents, solvents, and products involved. A grade of stainless steel that is perfect for one process may corrode rapidly in another.

It is crucial to verify chemical compatibility before any experiment to prevent vessel failure, leaks, and contamination of the final product.

Pressure Rating and Vessel Design

A reactor's maximum allowable pressure is directly related to its design, particularly its diameter. For a given material and wall thickness, a larger diameter vessel will have a lower pressure rating than a smaller one.

Glass reactors, in particular, have significantly lower pressure ratings than their metal counterparts and must be operated well within their specified limits.

The Inherent Risk of Stored Energy

A pressurized vessel contains a significant amount of stored energy. A sudden failure can result in a dangerous explosion, especially with glass reactors that may lack pressure relief mechanisms.

Proper engineering controls, including burst discs or relief valves, are non-negotiable safety features for managing overpressure events.

Maintenance and Routine Inspection

The integrity of a pressure reactor depends on its condition. Seals like O-rings can erode, and fittings on the vessel head can become damaged, leading to leaks.

Always examine equipment for wear and tear before use and ensure that service records are accessible and up to date. A well-maintained reactor is a safe reactor.

Making the Right Choice for Your Application

Your goal determines the right tool. Use these guidelines to select the appropriate type of pressure reactor for your work.

- If your primary focus is industrial production or high-pressure synthesis: Opt for a robust metal reactor and rigorously verify its chemical compatibility with your process materials.

- If your primary focus is process observation and development: A glass reactor is your best choice, but you must respect its lower pressure limits and confirm it has adequate safety features.

- If your primary focus is sterilization or disinfection: Choose a dedicated autoclave designed for medical or waste treatment, as it is optimized for safety, reliability, and repeatable cycles.

By understanding these core principles, you can select a pressure reactor that is not just a container, but a precise tool to achieve your scientific or industrial goals safely and effectively.

Summary Table:

| Application | Key Benefit | Reactor Type |

|---|---|---|

| Chemical Synthesis | Accelerates reactions, improves yields | Metal or Glass |

| Sterilization | Destroys microorganisms effectively | Autoclave |

| Process Observation | Visual monitoring of reactions | Glass |

| Industrial Production | Handles extreme pressures and temperatures | Metal |

Ready to enhance your lab's capabilities with a precision pressure reactor? At KINTEK, we specialize in high-quality lab equipment, including durable metal reactors for industrial synthesis and transparent glass reactors for R&D. Our experts will help you select the ideal vessel to ensure safety, improve yields, and scale your processes efficiently. Contact us today to discuss your specific application needs!

Visual Guide

Related Products

- Customizable Laboratory High Temperature High Pressure Reactors for Diverse Scientific Applications

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

People Also Ask

- Why are high-precision pressure sensors and temperature control systems critical for hydrothermal reaction equilibrium?

- Why must SCWG reactors maintain a specific heating rate? Protect Your High-Pressure Vessels from Thermal Stress

- Why are high-strength alloy tube reactors critical for HHIP? Ensuring Safety and Purity in High-Pressure Environments

- Why use high-pressure reactors for food waste pretreatment? Boost Hydrogen Production Efficiency Today!

- What is the advantage of using high-pressure hydrothermal reactors to treat biomass waste? Efficient Resource Recovery