At its core, vacuum evaporation is a physical vapor deposition (PVD) process that transforms a solid material into a thin, solid film on a target surface. This is achieved by heating the source material in a high-vacuum chamber until it vaporizes. The resulting gas particles then travel through the vacuum and condense onto a cooler substrate, forming the desired coating.

The fundamental purpose of the vacuum is to remove air and other gas molecules that would otherwise collide with the vaporized material. This ensures the particles have an unobstructed path to the substrate, resulting in a purer, more uniform, and higher-quality film.

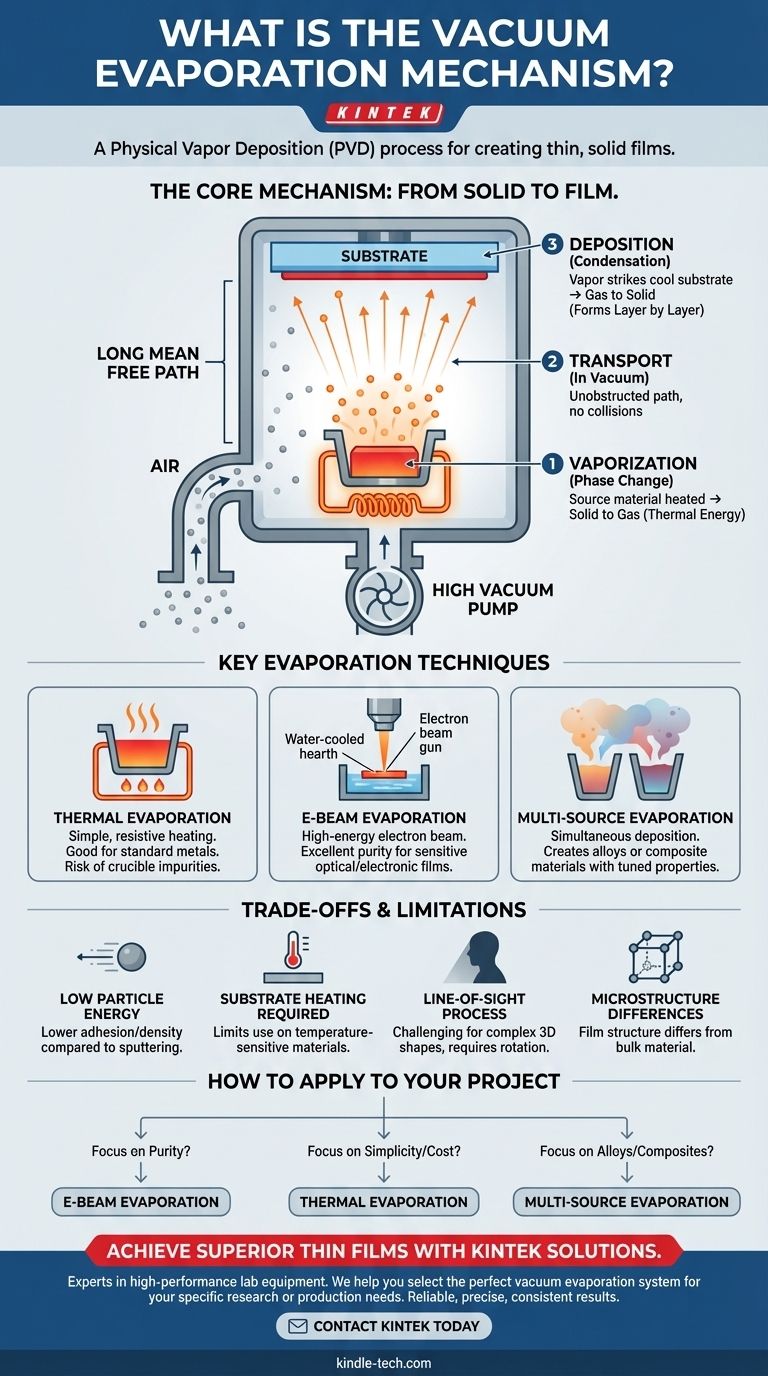

The Core Mechanism: From Solid to Film

The entire process hinges on a controlled phase transition within a highly controlled environment. Each step is critical to the quality of the final film.

The Role of the Vacuum

A vacuum is not just a setting; it's the most crucial element of the process. Performing this process near atmospheric pressure results in a non-uniform, "fuzzy" deposition because the evaporated particles constantly collide with air molecules.

By creating a vacuum, we significantly reduce the number of ambient gas particles. This long mean free path allows the vaporized source material to travel directly to the substrate without interference, contamination, or unwanted chemical reactions.

Phase Change: Vaporization of the Source

The process begins by heating a source material, known as the "charge," until it enters a gaseous state. This is done inside a crucible or hearth within the vacuum chamber.

The material transitions from solid to vapor, a process driven by thermal energy. The rate of evaporation is precisely controlled by adjusting the amount of energy applied to the source.

Deposition: Condensation on the Substrate

The vaporized particles travel outwards from the source in a straight line. When they strike the cooler surface of the substrate, they lose their thermal energy and condense back into a solid state.

This condensation builds up layer by layer, forming a thin film. The thickness of this film, often between 5 and 250 nanometers, is controlled by the evaporation rate and the duration of the deposition process.

Key Evaporation Techniques

While the principle remains the same, the method used to heat the source material defines the technique and its ideal applications.

Thermal Evaporation

This is one of the simplest methods. The source material is placed in a crucible, typically made of a refractory metal or ceramic, which is then heated by passing a high electrical current through it.

It is effective for a wide range of materials. However, a potential drawback is that the hot crucible itself can outgas or even evaporate slightly, introducing impurities into the film.

Electron Beam (E-Beam) Evaporation

In e-beam evaporation, a focused beam of high-energy electrons is directed at the source material, which rests in a water-cooled copper hearth. The intense, localized energy melts and vaporizes the material with extreme precision.

Because only the source material is heated while the surrounding hearth remains cool, this method produces exceptionally high-purity films. It is the preferred technique for sensitive optical and electronic applications.

Multi-Source Evaporation

To create films with a specific composition, such as metal alloys or composite materials, multiple sources can be operated simultaneously.

By precisely controlling the evaporation rate of each source, engineers can deposit a mixed vapor stream, allowing for the creation of films with finely tuned chemical, optical, or electrical properties.

Understanding the Trade-offs and Limitations

Vacuum evaporation is a powerful technique, but it is essential to understand its inherent limitations to apply it correctly.

Low Particle Energy

The particles travel from the source to the substrate with relatively low kinetic energy. They essentially "drift" and then condense.

This low energy means the film's adhesion and density can be lower compared to higher-energy processes like sputtering.

The Need for Substrate Heating

To compensate for the low particle energy and improve the film's structural quality and adhesion, the substrate is often heated to several hundred degrees Celsius (e.g., 250-350 °C).

This requirement limits the types of substrates that can be used. For example, many plastics or other temperature-sensitive materials cannot be coated using this method without potential damage.

Microstructure Differences

The resulting film often has a microstructure that is significantly different from the bulk source material. This is a direct consequence of the atom-by-atom condensation process. While this can be engineered for specific properties, it must be carefully managed.

A Note on Other Applications

The principle of vacuum evaporation is also used in other fields, such as wastewater treatment. In that context, a vacuum is used to lower the boiling point of water, allowing it to evaporate and separate from contaminants efficiently. This is a separation process, not a deposition process for creating films.

How to Apply This to Your Project

Your choice of technique depends entirely on the required properties of your final film.

- If your primary focus is the highest possible purity: E-beam evaporation is the clear choice, as it minimizes contamination from the heating apparatus.

- If your primary focus is simplicity or coating standard metals: Thermal evaporation is often a sufficient and more cost-effective solution for applications like decorative coatings or basic metallization.

- If your primary focus is creating an alloy or composite film: Multi-source evaporation is the only method that allows for the simultaneous deposition of different materials.

- If your primary focus is coating a complex 3D shape: Be aware that vacuum evaporation is a line-of-sight process, and achieving uniform coverage will require sophisticated substrate rotation mechanisms.

By understanding these core mechanisms and trade-offs, you can select and control the vacuum evaporation process to achieve the precise film properties your application demands.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Process Type | Physical Vapor Deposition (PVD) |

| Core Principle | Heating a solid source in a vacuum to vaporize it, then condensing the vapor onto a cooler substrate. |

| Key Techniques | Thermal Evaporation, Electron Beam (E-Beam) Evaporation, Multi-Source Evaporation |

| Primary Advantage | Creates high-purity, uniform thin films. |

| Main Limitation | Line-of-sight process; can have lower adhesion and requires substrate heating. |

Ready to achieve superior thin films for your research or production?

At KINTEK, we specialize in high-performance lab equipment, including vacuum evaporation systems tailored for your specific needs. Whether you require the ultimate purity of e-beam evaporation or the simplicity of thermal evaporation, our experts can help you select the perfect solution.

We provide reliable equipment and consumables that ensure precise temperature control, high vacuum integrity, and consistent results for laboratories in electronics, optics, and materials science.

Contact KINTEK today to discuss your project and discover how our vacuum evaporation technology can enhance your lab's capabilities.

Visual Guide

Related Products

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

People Also Ask

- How does electron beam curing work? Achieve Instant, Durable Curing for Industrial Applications

- What is evaporation and sputtering? Choose the Right PVD Method for Your Thin Film Needs

- What is the function of electron coating? Boost Your Device's Electrical & Optical Performance

- How does electron beam evaporation work? Achieve Ultra-Pure, High-Performance Thin Films

- What is the rate of electron beam evaporation? Unlock High-Speed, High-Temperature Deposition

- What is the evaporation technique for deposition? A Guide to High-Purity Thin Film Coating

- What is the vacuum evaporation plating method? A Guide to Simple, Cost-Effective Thin Film Coating

- What materials are used in evaporation techniques? A Guide to Thin-Film Deposition Materials