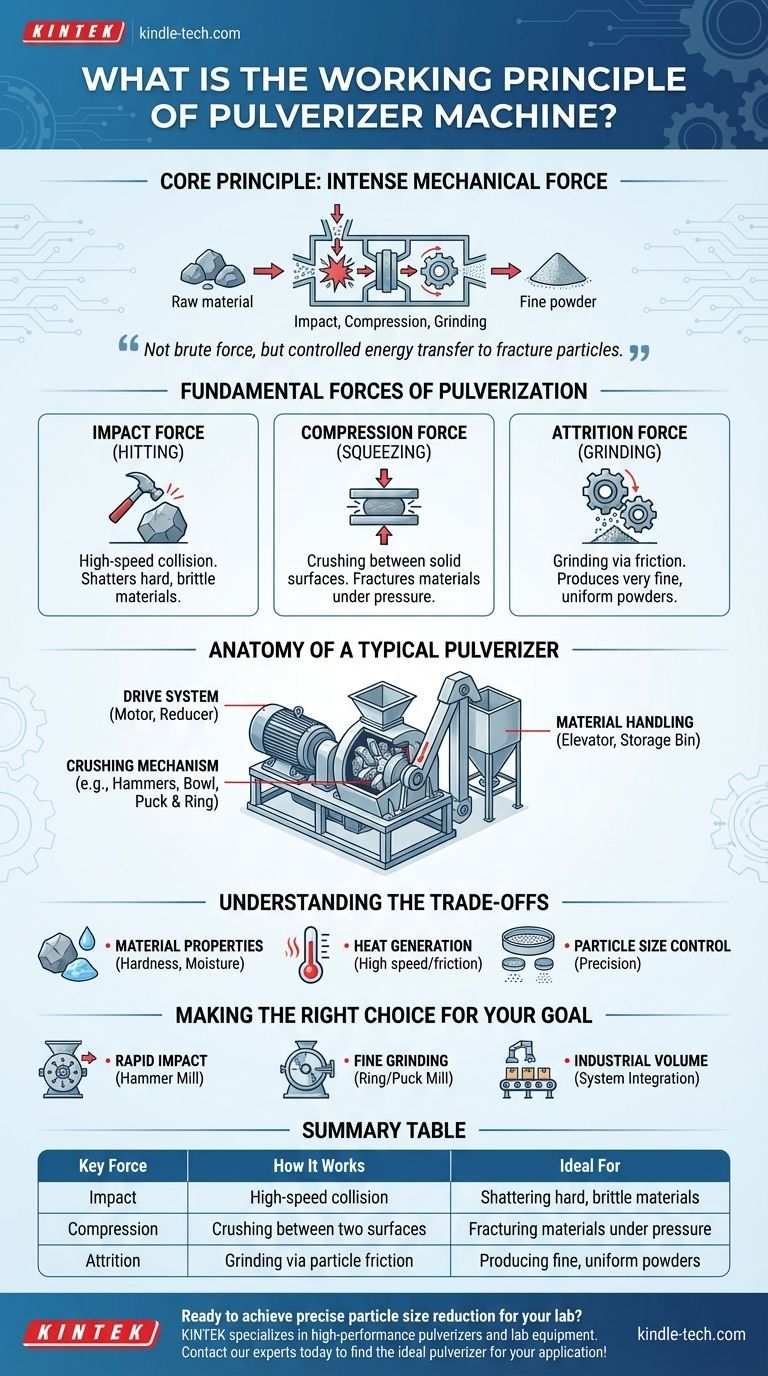

At its core, a pulverizer works by applying intense mechanical force to break down large, coarse materials into fine, uniform powders. This is achieved by a motor driving a specialized mechanism that uses a combination of impact, compression, and grinding forces. The specific method—whether it's high-speed hammering or crushing with a bowl and puck—is determined by the machine's design and the material being processed.

A pulverizer's function isn't just about brute force; it's about controlled energy transfer. The machine's design dictates how it introduces impact, attrition, and compression forces to fracture material particles until they reach a desired, consistent size.

The Fundamental Forces of Pulverization

To truly understand how a pulverizer works, you must first understand the three primary forces it uses to achieve size reduction. Nearly every pulverizer design emphasizes one or more of these principles.

Impact Force (Hitting)

Impact is the primary force in many pulverizers, such as hammer mills. It involves a high-speed collision between the material and a moving part of the machine (like a hammer) or the chamber wall.

This sharp, sudden force is extremely effective at shattering hard, brittle materials into smaller pieces.

Compression Force (Squeezing)

Compression involves crushing material between two solid surfaces. Think of it as a squeezing action.

This force is applied as components like rings or pucks press against the material and the grinding bowl. It is ideal for breaking down materials that can withstand initial impact but will fracture under sustained pressure.

Attrition Force (Grinding)

Attrition is the force of grinding, generated when particles rub against each other or against the machine's grinding surfaces.

This shearing action is what produces very fine, uniform powders. In machines like ring or puck mills, this happens as the grinding components spin at high speed due to centrifugal force, creating intense friction.

Anatomy of a Typical Pulverizer

While designs vary, most pulverizers share a common set of core components that work together to apply the forces described above.

The Drive System

The entire process begins with a powerful electric motor. This motor provides the rotational energy needed to operate the machine at high speeds.

In some larger systems, the motor connects to a reducer, which manages the speed and torque delivered to the main shaft.

The Crushing Mechanism

This is the heart of the machine where the size reduction occurs. The design of this mechanism determines the primary forces used.

Common examples include:

- Hammers: A series of hammers attached to a high-speed rotor (or main shaft) that repeatedly strike the material.

- Bowl, Puck, and Ring: Components inside a sealed chamber that are driven by vibration and centrifugal force to hit, squeeze, and grind the sample.

Material Handling Components

In larger, industrial settings, the pulverizer is part of a system. This can include an elevator to feed coarse material into the machine and a storage bin to collect the finished powder.

Understanding the Trade-offs

Choosing or operating a pulverizer requires understanding its inherent limitations and how its design affects the final product.

Material Properties are Critical

The effectiveness of a pulverizer is highly dependent on the material being processed. Hardness, moisture content, and abrasiveness will dictate which type of force—and therefore which machine—is most efficient.

Heat Generation

The high speeds and friction involved in pulverization generate significant heat. This can be a major problem for heat-sensitive materials, potentially altering their chemical composition or physical properties.

Particle Size Control

Different machines offer different levels of control over the final particle size. Impact-based machines are excellent for rapid size reduction, while attrition-based machines provide more precision for creating very fine, homogenous powders for lab analysis.

Making the Right Choice for Your Goal

To select the right approach, you must match the pulverizer's primary working principle to your desired outcome.

- If your primary focus is rapid processing of hard, brittle materials: Look for pulverizers that rely heavily on impact force, such as a hammer mill.

- If your primary focus is achieving a very fine, uniform powder for R&D: Consider a machine using attrition and compression, like a ring or puck mill, which offers precise grinding.

- If your primary focus is processing large volumes in an industrial line: Your choice will be part of a larger system, where factors like feed rate and integration with conveyors are key.

Understanding these core principles empowers you to see beyond the machine and focus on the forces required to achieve your material processing goals.

Summary Table:

| Key Force | How It Works | Ideal For |

|---|---|---|

| Impact | High-speed collision (e.g., hammer mills) | Shattering hard, brittle materials |

| Compression | Crushing between two surfaces | Fracturing materials under pressure |

| Attrition | Grinding via particle friction | Producing fine, uniform powders |

Ready to achieve precise particle size reduction for your lab? KINTEK specializes in high-performance pulverizers and lab equipment, offering solutions tailored to your material processing needs—whether for rapid crushing or fine grinding. Contact our experts today to find the ideal pulverizer for your application!

Visual Guide

Related Products

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What is the function of a high-energy planetary ball mill in zirconium-doped CaO synthesis? Optimize Material Stability

- How does a planetary ball mill enhance the electrocatalytic activity of La0.6Sr0.4CoO3-δ? Boost Your Catalyst Performance

- How does a planetary high-energy ball mill contribute to the top-down preparation of layered materials? Optimize Yield

- What is the function of a high-energy planetary ball mill in the synthesis of iodo-vanadate-lead ceramic waste forms?

- Why is a high-energy planetary ball mill preferred over traditional casting for nanocrystalline HEAs?