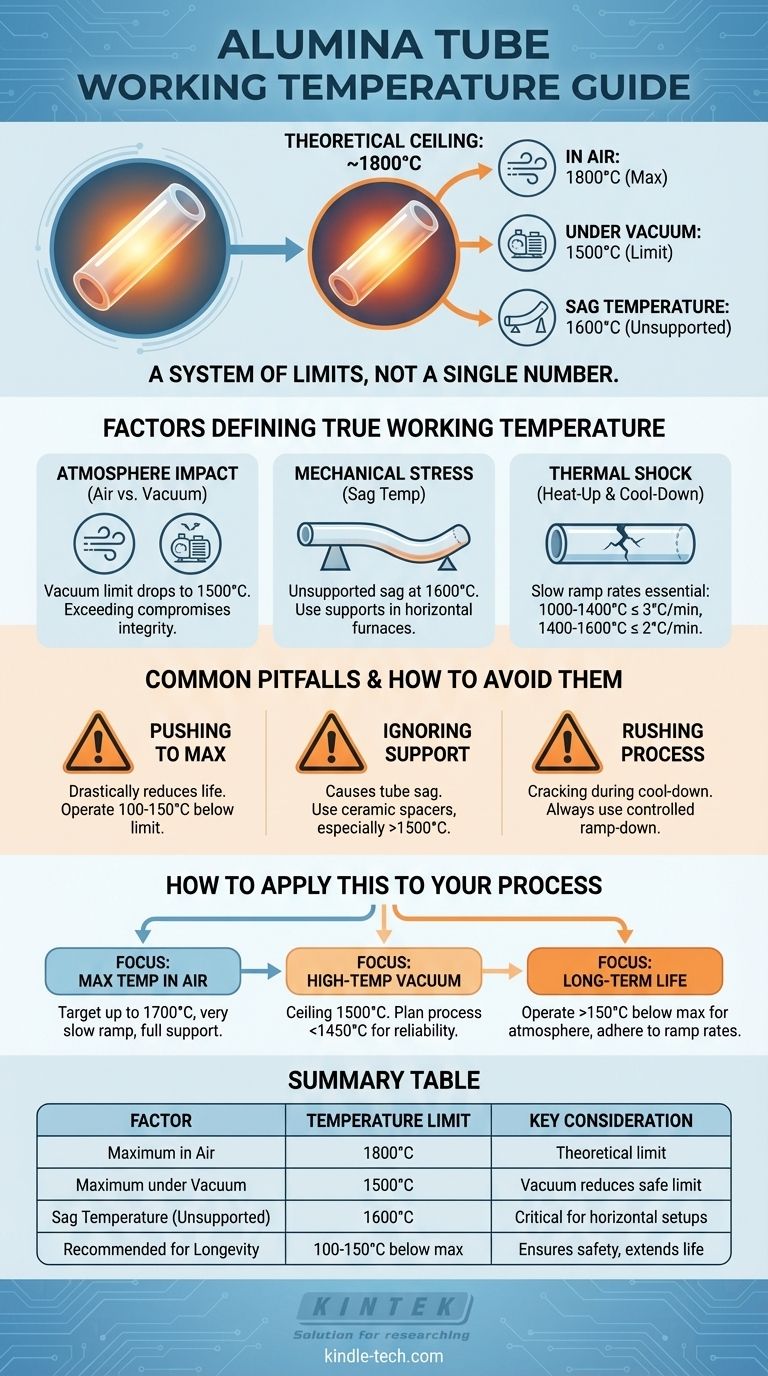

In short, the maximum working temperature of a high-purity alumina tube is approximately 1800°C. However, this number is a theoretical ceiling, not a daily operating target. Your actual, safe working temperature is significantly influenced by the operating atmosphere, the physical support for the tube, and how quickly you change the temperature.

The key takeaway is that an alumina tube's temperature limit is not a single number. It is a system of limits defined by its environment: 1800°C in air, 1500°C under vacuum, and a physical "sag" temperature of 1600°C if left unsupported.

The Factors Defining Your True Working Temperature

To use an alumina tube successfully, you must operate within its practical limits, which are always lower than the material's theoretical maximum. These factors are non-negotiable for ensuring safety and the longevity of the tube.

The 1800°C Benchmark

High-purity alumina tubes (typically 99.5% to 99.8% Al₂O₃) are engineered for extreme heat. The 1800°C (approx. 3272°F) figure represents the material's upper limit in a standard atmosphere (1 atm).

Impact of Atmosphere: Air vs. Vacuum

The environment inside the tube is a critical limiting factor. Operating under a vacuum significantly reduces the maximum safe temperature.

The limit drops to 1500°C under vacuum conditions. Exceeding this can compromise the material's integrity.

Mechanical Stress: The Sag Temperature

At extreme temperatures, ceramics can soften and deform under their own weight. This is a crucial concept for any horizontal tube furnace setup.

The unsupported sag temperature for an alumina tube is 1600°C. Above this temperature, a tube that is not properly supported along its length will begin to bend and fail.

Thermal Shock: Controlling Heat-Up and Cool-Down

Alumina is a brittle ceramic. Rapid temperature changes create internal stress that will cause it to crack. Adhering to controlled heating and cooling rates is essential for the tube's survival.

A conservative ramp rate is critical, especially at higher temperatures. Recommended rates are:

- 1000-1400°C: ≤ 3°C per minute

- 1400-1600°C: ≤ 2°C per minute

Common Pitfalls and How to Avoid Them

Understanding the risks associated with pushing the material to its limits is key to preventing catastrophic and costly failures.

Pushing to the Absolute Maximum

Continuously operating any material at its absolute temperature limit drastically reduces its service life. It is standard practice to operate at least 100-150°C below the stated maximum for consistent, reliable performance.

Ignoring Mechanical Support

The most common failure in horizontal tube furnaces is tube sag. Ensure the tube is well-supported with ceramic spacers, especially for long tubes or temperatures exceeding 1500°C.

Rushing the Process

Cracking during cool-down is a frequent and expensive mistake. Never open the furnace to "speed up" the cooling process. Always program a slow, controlled ramp-down cycle.

How to Apply This to Your Process

Your ideal operating temperature depends entirely on your specific goal and setup.

- If your primary focus is maximum temperature in air: You can safely target up to 1700°C, provided you use very slow ramp rates and ensure the tube is fully supported.

- If your primary focus is high-temperature work under vacuum: Your absolute ceiling is 1500°C. For reliable, repeatable work, plan your process to stay below 1450°C.

- If your primary focus is long-term tube life and reliability: Operate at least 150°C below the maximum for your given atmosphere and strictly adhere to the recommended heating and cooling rates.

By respecting the material's properties and its environmental limits, you ensure safe, successful, and repeatable results.

Summary Table:

| Factor | Temperature Limit | Key Consideration |

|---|---|---|

| Maximum in Air | 1800°C | Theoretical limit for high-purity Al₂O₃ |

| Maximum under Vacuum | 1500°C | Vacuum conditions reduce safe operating temperature |

| Sag Temperature (Unsupported) | 1600°C | Critical for horizontal tube furnace setups |

| Recommended for Longevity | 100-150°C below max | Ensures safety and extends tube service life |

Need a high-performance alumina tube or expert advice for your lab's high-temperature applications? KINTEK specializes in premium lab equipment and consumables, including alumina tubes designed for durability and precise thermal performance. Our team can help you select the right tube for your specific atmosphere and temperature requirements, ensuring safety and maximizing your furnace's efficiency. Contact us today to discuss your project and get a personalized solution!

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory High Pressure Vacuum Tube Furnace

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What are the conditions for thermal cracking? Achieve Optimal Hydrocarbon Conversion with Precision Control

- What are the primary considerations for using a quartz tube reactor in DMSTA? Ensure Analytical Precision

- What are the low cost catalysts for pyrolysis? Optimize Your Pyrolysis Process with Affordable Catalysts

- What is a drop tube furnace? A Specialized Reactor for Particle-Level Research

- Why Use a Quartz Tube Reactor for Y-Ti-O Phase Transformations? Achieve Absolute Purity and Precision Control

- What function does a laboratory tube furnace serve in the activation of Au/TiO2 catalysts? Engineer Active Sites

- What is RTA rapid temperature annealing? Achieve Precise Material Processing in Seconds

- How do tube furnaces or muffle furnaces ensure stoichiometric accuracy during synthesis? Mastering Li4GeO4 & Li4VO4