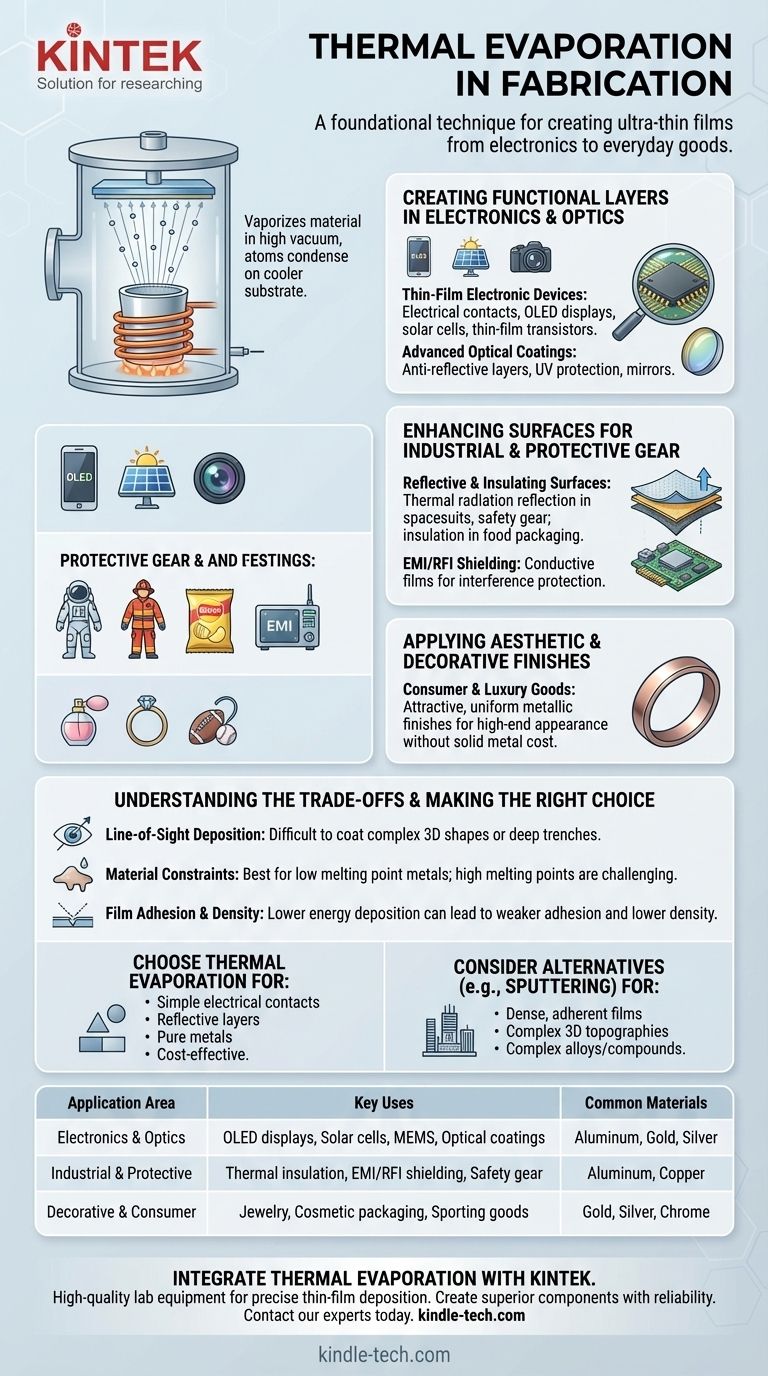

In fabrication, thermal evaporation is a foundational technique used to create ultra-thin films for a vast range of products, from advanced electronics to everyday consumer goods. This method involves heating a material in a high-vacuum chamber until it vaporizes, allowing its atoms to travel and condense onto a cooler substrate, forming a precise, thin coating. This process is essential for manufacturing components like OLED displays, solar cells, and reflective coatings on automotive headlights.

At its core, thermal evaporation is about controllably depositing a very thin layer of material onto a surface. This simple principle is the key to creating critical functional layers, such as electrical contacts in microchips and protective barriers on food packaging, across dozens of industries.

Creating Functional Layers in Electronics and Optics

The most common use of thermal evaporation is in the production of high-technology devices where thin, pure films are critical for performance.

Thin-Film Electronic Devices

Thermal evaporation is used to deposit electrical contacts and other conductive layers. Single metals like aluminum, gold, or silver are easily evaporated to create the pathways for electricity to flow in a circuit.

This is a cornerstone of manufacturing OLED displays, solar cells, and thin-film transistors, where precise layers of metallic or non-metallic materials are required to build the device's functional stack.

Microelectromechanical Systems (MEMS)

In the fabrication of MEMS, thermal evaporation is used to deposit structural or sacrificial layers. These tiny mechanical devices rely on the precise application of thin films to function correctly.

Advanced Optical Coatings

The technique is widely used in the optics industry to modify the properties of surfaces. It can create anti-reflective layers on camera lenses, apply protective UV coatings to eyeglasses, and produce highly reflective surfaces for mirrors and reflectors used in automotive and aerospace applications.

Enhancing Surfaces for Industrial and Protective Gear

Beyond electronics, thermal evaporation is used to impart specific physical properties to the surface of a material, enhancing its durability, function, or safety.

Reflective and Insulating Surfaces

The shiny, metallic layer inside a bag of chips is often made by evaporating a thin film of aluminum onto a polymer. This same principle is used for creating heat and sound insulation in aircraft and for high-performance protective gear.

Applications include the reflective coatings on NASA spacesuits, firefighter uniforms, and emergency blankets, all of which rely on a thin metal layer to reflect thermal radiation.

EMI/RFI Shielding

Electronic devices can be shielded from electromagnetic interference (EMI) and radio-frequency interference (RFI) by coating their enclosures with a thin conductive film applied via thermal evaporation.

Applying Aesthetic and Decorative Finishes

The ability to create a thin, uniform metallic coating makes thermal evaporation a popular choice for purely decorative purposes.

Consumer and Luxury Goods

This technique is used to apply attractive finishes to items like cosmetic closures, sporting goods, and jewelry. It provides a high-end metallic appearance without the cost or weight of using solid metal.

Understanding the Trade-offs

While incredibly versatile, thermal evaporation is not the solution for every thin-film challenge. Its effectiveness is governed by its underlying physics.

Line-of-Sight Deposition

Thermal evaporation is a line-of-sight process, meaning the vaporized material travels in a straight line to the substrate. This makes it difficult to uniformly coat complex, three-dimensional shapes or the inside of deep trenches.

Material Constraints

The process works best for materials with relatively low melting points, such as aluminum, gold, and silver. Evaporating materials with very high melting points (refractory metals) or complex compounds can be challenging and may require more advanced techniques.

Film Adhesion and Density

Because the atoms arrive at the substrate with relatively low energy, the resulting films can sometimes have weaker adhesion and lower density compared to films deposited with higher-energy methods like sputtering.

Making the Right Choice for Your Goal

Selecting the right deposition method depends entirely on your material, substrate, and desired outcome.

- If your primary focus is depositing simple electrical contacts or reflective layers of pure metals: Thermal evaporation is an excellent, highly reliable, and cost-effective choice.

- If your primary focus is creating dense, highly adherent films or coating complex 3D topographies: You should investigate alternative methods like sputter deposition, which provides better coverage and film quality for these scenarios.

- If your primary focus is depositing complex alloys or stoichiometric compounds: While co-evaporation is possible with careful control, other techniques like sputtering from a composite target may offer more consistent results.

Ultimately, thermal evaporation serves as a versatile and fundamental tool for any fabrication process requiring the precise application of a thin material film.

Summary Table:

| Application Area | Key Uses | Common Materials |

|---|---|---|

| Electronics & Optics | OLED displays, solar cells, MEMS, anti-reflective coatings | Aluminum, Gold, Silver |

| Industrial & Protective | Thermal insulation, EMI/RFI shielding, reflective safety gear | Aluminum, Copper |

| Decorative & Consumer | Jewelry, cosmetic packaging, sporting goods | Gold, Silver, Chrome |

Ready to integrate thermal evaporation into your fabrication process? KINTEK specializes in high-quality lab equipment and consumables for precise thin-film deposition. Our solutions help you create superior electronic components, optical coatings, and protective layers with reliability and efficiency. Contact our experts today to discuss your specific application needs and discover the right equipment for your laboratory.

Visual Guide

Related Products

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- What is the thermal evaporation technique? A Guide to Thin-Film Deposition for Your Lab

- What is thermal evaporation used to deposit? A Guide to Metals, Compounds, and Key Applications

- What are the drawbacks of thermal evaporation? Understanding the Limitations for High-Performance Applications

- What is thermal effect via evaporation? A Simple Guide to Thin-Film Deposition

- What is the difference between sputtering and thermal evaporation? Choose the Right PVD Method for Your Thin Film