In essence, thermally activated Chemical Vapor Deposition (CVD) is a process that uses high temperatures to create thin films of solid material from a gas. A substrate is heated inside a chamber, and precursor gases are introduced, which then react or decompose on the hot surface to form the desired coating. It is the most fundamental and conventional form of CVD.

Thermal CVD is the foundational method for growing high-purity, dense films. Its defining characteristic is the reliance on heat as the sole energy source, which is both its strength in producing quality films and its primary limitation due to the high temperatures required.

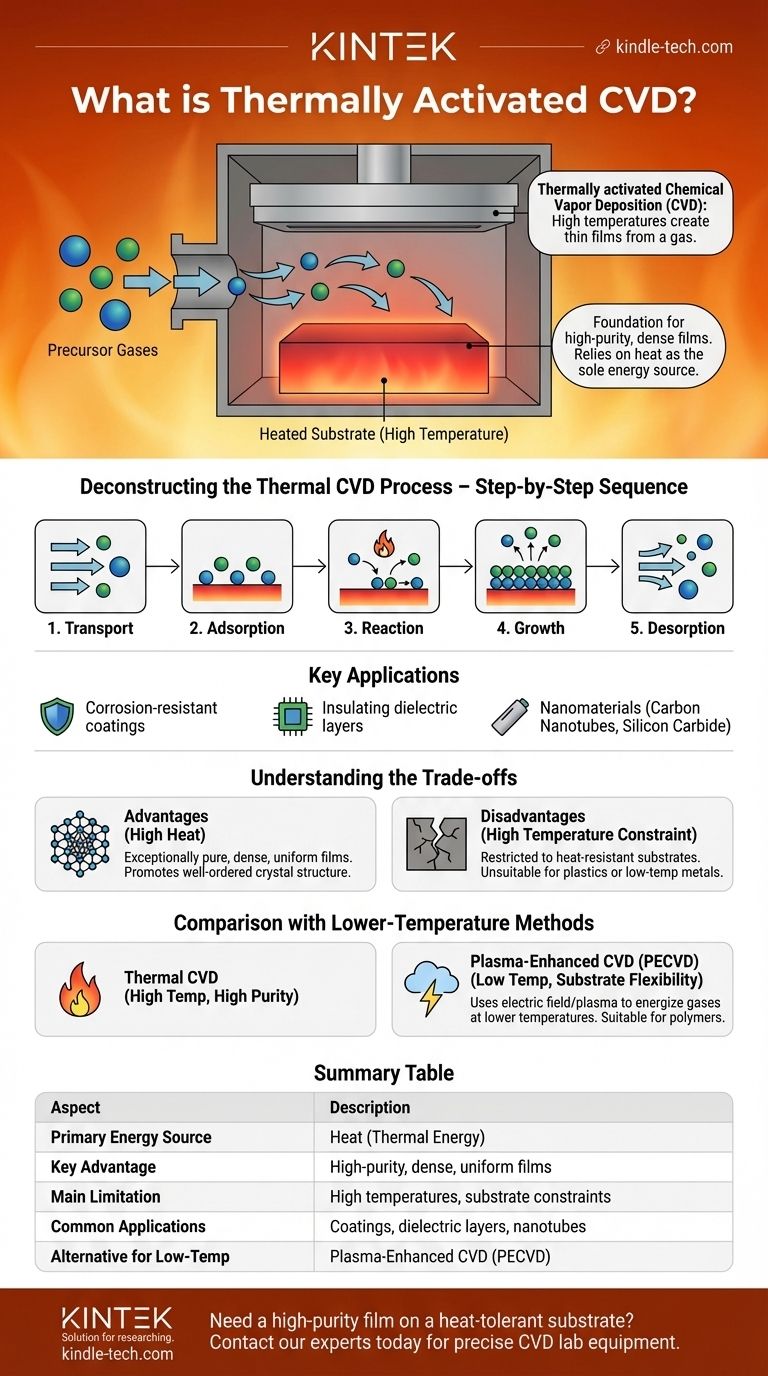

Deconstructing the Thermal CVD Process

To understand thermally activated CVD, it's best to break it down into its core components and sequence of events. The entire process is driven by thermal energy.

The Role of Heat as the Catalyst

The "thermally activated" part of the name is the key. In this process, the substrate is heated to a specific, often very high, temperature.

This thermal energy is transferred to the precursor gas molecules that come into contact with the surface, providing the activation energy needed to break their chemical bonds.

The Step-by-Step Deposition Sequence

The formation of a film via thermal CVD is a multi-stage process:

- Transport: Precursor gases are delivered into the reaction chamber.

- Adsorption: Gas molecules stick to the heated substrate surface.

- Reaction: The high surface temperature causes the adsorbed molecules to decompose or react, leaving behind the desired solid atoms.

- Growth: These atoms diffuse across the surface and arrange themselves into a growing film or nanostructure.

- Desorption: Gaseous byproducts from the chemical reaction are released from the surface and transported out of the chamber.

Key Applications and Materials

This method is highly versatile and is used to synthesize a wide range of materials and structures.

Common applications include creating corrosion-resistant coatings, insulating dielectric layers for electronics, and growing specialized nanomaterials like carbon nanotubes or silicon carbide nanorods.

Understanding the Trade-offs

While powerful, the reliance on high heat creates a distinct set of advantages and disadvantages that determine when thermal CVD is the appropriate choice.

The High-Temperature Constraint

The most significant limitation of thermal CVD is its requirement for high reaction temperatures.

This restricts its use to substrates that can withstand the heat without melting, deforming, or degrading. It is generally unsuitable for coating plastics, certain metals, or other temperature-sensitive materials.

Purity and Density vs. Temperature

The primary advantage of using high heat is the ability to produce exceptionally pure, dense, and uniform films. The high thermal energy facilitates efficient chemical reactions and promotes the formation of a well-ordered crystal structure.

Comparison with Lower-Temperature Methods

To overcome the temperature limitation, other CVD methods were developed. Plasma-Enhanced CVD (PECVD), for example, uses an electric field to create a plasma.

This plasma energizes the precursor gases, allowing the chemical reactions to occur at much lower temperatures. This makes PECVD suitable for temperature-sensitive substrates, though it can introduce complexities not present in the simpler thermal process.

Making the Right Choice for Your Goal

Selecting the correct deposition method depends entirely on the properties of your substrate and the desired quality of the final film.

- If your primary focus is maximum film purity on a heat-tolerant substrate: Thermal CVD is often the ideal choice due to its simplicity and the high quality of the resulting film.

- If your primary focus is depositing a film on a temperature-sensitive material like a polymer: You must use a lower-temperature method like Plasma-Enhanced CVD (PECVD).

Ultimately, your choice is a trade-off between the material constraints of your substrate and the specific film characteristics you need to achieve.

Summary Table:

| Aspect | Description |

|---|---|

| Primary Energy Source | Heat (Thermal Energy) |

| Key Advantage | Produces high-purity, dense, uniform films |

| Main Limitation | Requires high temperatures, limiting substrate choice |

| Common Applications | Corrosion-resistant coatings, dielectric layers, carbon nanotubes |

| Alternative for Low-Temp | Plasma-Enhanced CVD (PECVD) |

Need to deposit a high-purity film on a heat-tolerant substrate?

Thermally activated CVD is a foundational technique for achieving superior film quality. At KINTEK, we specialize in providing the precise lab equipment and consumables needed for reliable CVD processes. Our expertise ensures your laboratory can achieve consistent, high-performance results.

Let's discuss your specific application. Contact our experts today to find the ideal CVD solution for your research or production goals.

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What role does Chemical Vapor Deposition (CVD) equipment play in the preparation of C/C composites? Expert Analysis

- How high of temperature do carbon nanotubes in air have the ability to sustain? Understanding the Oxidation Limit

- What are the methods of producing CNT? Scalable CVD vs. High-Purity Lab Techniques

- Why are carbon nanotubes important in industry? Unlocking Next-Generation Material Performance

- How does chirality affect carbon nanotubes? It Determines If They Are Metal or Semiconductor