Waste tire pyrolysis is a thermal decomposition process that converts discarded tires into valuable products such as fuel oil, carbon black, uncondensable gas, and steel wire. This process involves heating waste tires in a sealed, oxygen-free environment, causing the rubber to break down into smaller molecules. The resulting products have various industrial applications, making pyrolysis an environmentally friendly and efficient recycling method. The process is highly dependent on factors like temperature, reactor design, and tire composition, which influence the quality and yield of the end products.

Key Points Explained:

-

Definition of Waste Tire Pyrolysis

Waste tire pyrolysis is a thermochemical process where waste tires are heated in the absence of oxygen, causing the rubber to decompose into smaller molecules. This process breaks down the long polymer chains in rubber into monomers, biopolymers, and fragments, which then recombine into useful products like fuel oil, carbon black, and gas. -

Working Principle

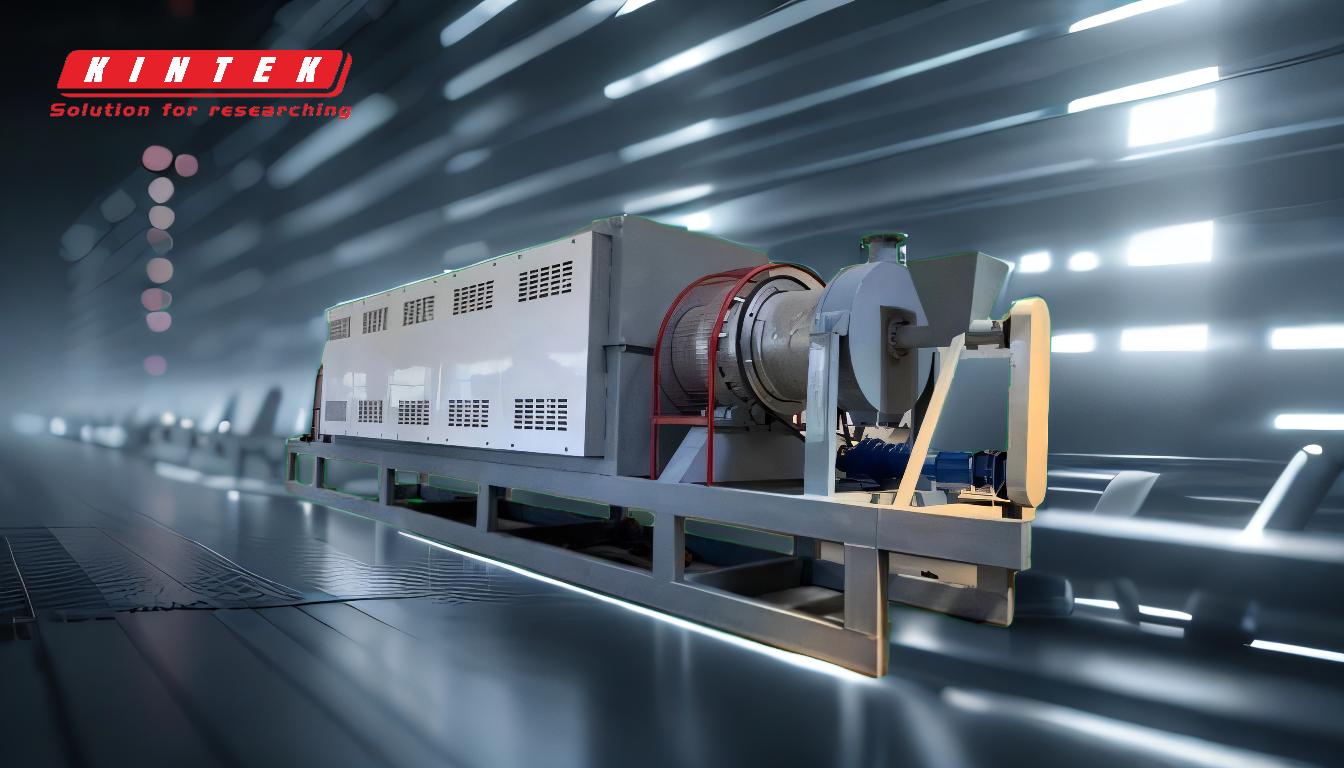

- Waste tires are placed into a pyrolysis reactor, typically a rotary kiln, which is sealed to prevent oxygen from entering.

- The reactor is heated, causing the rubber to undergo anaerobic cracking.

- The reactor rotates to ensure uniform heating and efficient pyrolysis of the tires.

-

End Products

The pyrolysis process yields several valuable products:- Fuel Oil: A liquid product that can be used as an industrial fuel or further refined.

- Carbon Black: A solid residue used in manufacturing rubber products, inks, and coatings.

- Uncondensable Gas: A gaseous byproduct that can be used to fuel the pyrolysis process itself.

- Steel Wire: Extracted during pretreatment, it can be sold or recycled for other industrial uses.

-

Process Steps

The waste tire pyrolysis process involves several key stages:- Pretreatment: Tires are shredded and subjected to magnetic separation to remove steel wires.

- Depolymerization: The shredded tires are heated in the reactor, causing the rubber to break down.

- Cracking: The rubber fragments undergo further decomposition into smaller molecules.

- Heat Exchange: The gases and vapors are cooled to condense the fuel oil.

- Slag Discharge: The remaining solid residue (carbon black) is automatically discharged.

-

Environmental Benefits

- The process is eco-friendly, as it does not produce harmful emissions or waste.

- It recycles 100% of the waste tires, reducing landfill usage and environmental pollution.

- The end products are valuable raw materials that can replace virgin resources in various industries.

-

Factors Affecting the Process

- Temperature: The pyrolysis temperature significantly influences the composition and yield of the end products.

- Reactor Design: The type of reactor (e.g., rotary kiln) and its efficiency impact the uniformity of heating and product quality.

- Tire Composition: The materials used in tire manufacturing (e.g., natural rubber, synthetic rubber, additives) affect the pyrolysis outcomes.

-

Applications of Pyrolysis Products

- Fuel Oil: Used as an alternative to traditional fossil fuels in industrial boilers and furnaces.

- Carbon Black: Utilized in the production of tires, rubber goods, and pigments.

- Steel Wire: Recycled for use in construction and manufacturing.

- Uncondensable Gas: Provides energy for the pyrolysis process, reducing reliance on external fuel sources.

By converting waste tires into valuable resources, pyrolysis offers a sustainable solution to the growing problem of tire waste, while also contributing to the circular economy.

Summary Table:

| Aspect | Details |

|---|---|

| Definition | Thermal decomposition of waste tires in an oxygen-free environment. |

| End Products | Fuel oil, carbon black, uncondensable gas, and steel wire. |

| Process Steps | Pretreatment, depolymerization, cracking, heat exchange, slag discharge. |

| Environmental Benefits | Eco-friendly, reduces landfill usage, and recycles 100% of waste tires. |

| Applications | Fuel oil for industrial use, carbon black for manufacturing, steel recycling. |

Discover how waste tire pyrolysis can benefit your business—contact us today for more information!