To protect your irreplaceable samples, the most essential maintenance practices for an Ultra-Low Temperature (ULT) freezer are regular cleaning of condenser coils, routine inspection of door gaskets for a perfect seal, clearing internal ice buildup, and continuous temperature monitoring. These actions directly prevent the mechanical strain and temperature fluctuations that lead to catastrophic equipment failure and sample loss.

A ULT freezer is not a "set it and forget it" appliance. Effective maintenance is a proactive strategy that combines routine mechanical checks with systematic monitoring to guarantee the long-term integrity of your samples and the operational efficiency of the unit.

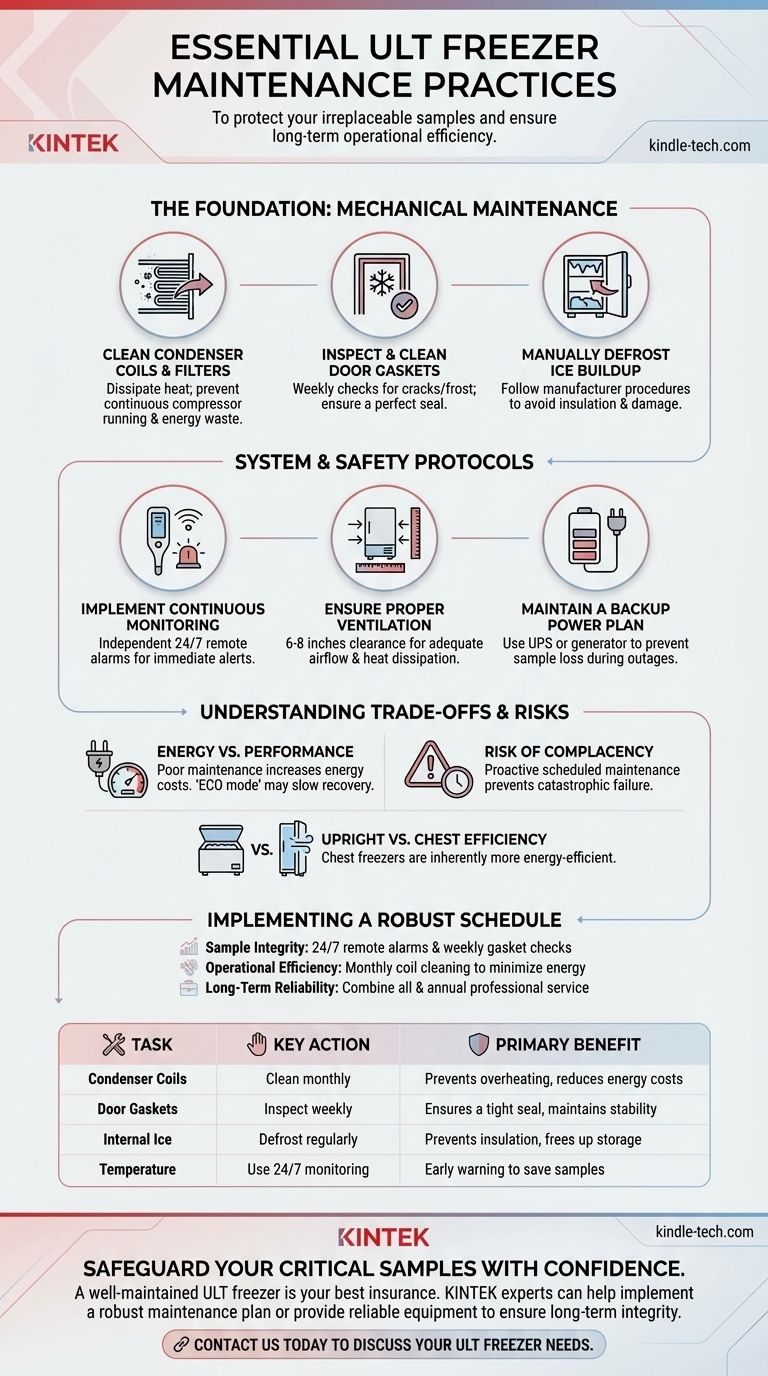

The Foundation: Proactive Mechanical Maintenance

Your freezer's ability to maintain its ultra-low temperature depends on a few critical mechanical components. Neglecting them forces the entire system to work harder, increasing energy consumption and the risk of a complete breakdown.

Clean Condenser Coils and Filters

The condenser coils are responsible for dissipating heat away from the freezer unit. When they become clogged with dust and debris, heat gets trapped.

This forces the compressors to run continuously to maintain temperature, leading to excessive energy use and a significantly shorter lifespan for the cooling system.

Inspect and Clean Door Gaskets

The door gasket is the single most critical barrier against the ambient environment. Inspect it weekly for any signs of cracks, brittleness, or frost buildup.

Frost on the gasket is a clear indicator of an air leak. A compromised seal allows warm, moist air to enter, causing temperature instability and forcing the freezer to overwork to compensate.

Manually Defrost Ice Buildup

While a small amount of frost is normal, significant ice buildup acts as an insulator, reducing cooling efficiency and storage space.

Excess ice can also place physical pressure on the inner doors and seals, leading to damage. Follow the manufacturer's specific procedures for safe defrosting to avoid harming the cooling system or your samples.

Beyond the Machine: System & Safety Protocols

Mechanical health is only one part of the equation. A robust maintenance plan includes the systems and procedures surrounding the freezer itself.

Implement Continuous Temperature Monitoring

Relying on the freezer's built-in display is not enough. An independent, 24/7 temperature monitoring system with remote alarms is your first and best line of defense.

This system will alert designated personnel via phone or email the moment a temperature deviation occurs, providing a critical window to save samples before they are compromised.

Ensure Proper Ventilation

ULT freezers generate a significant amount of heat. Ensure there is adequate clearance around the unit—typically 6-8 inches on all sides—to allow for proper airflow.

Placing a freezer in a small, unventilated room or directly against a wall will trap heat, reducing efficiency and leading to premature component failure.

Maintain a Backup Power Plan

A power outage is one of the most common causes of catastrophic sample loss. Your freezer must be connected to a backup power source, such as an uninterruptible power supply (UPS) for short-term stability or a facility-wide backup generator.

Understanding the Trade-offs and Risks

Operating a ULT freezer involves balancing performance with operational realities. Understanding these factors is key to making informed decisions.

Energy Consumption vs. Performance

A poorly maintained freezer is an energy hog. Clogged coils and leaking gaskets can dramatically increase electricity costs as the unit struggles to maintain its setpoint.

While features like "ECO mode" can reduce energy use, they may also slow temperature recovery after door openings. Understand this trade-off based on how frequently you access the freezer.

The Risk of Complacency

The single greatest risk is assuming the freezer will run perfectly without intervention. Small issues like a minor gasket tear or dust on a filter can cascade into complete system failure over time.

Regular, scheduled maintenance transforms your approach from reactive crisis management to proactive risk prevention, safeguarding against sample degradation, freezer burn, and contamination.

Upright vs. Chest Freezer Efficiency

Chest freezers are inherently more energy-efficient because cold, dense air does not spill out when the top-opening lid is lifted.

With an upright freezer, cold air immediately flows out the bottom of the door opening. This makes diligent gasket inspection and minimizing door-open times even more critical for maintaining both temperature stability and energy efficiency.

Implementing a Robust Maintenance Schedule

Your maintenance strategy should be tailored to your primary operational goals. A simple schedule ensures these critical tasks are never overlooked.

- If your primary focus is absolute sample integrity: Prioritize implementing a 24/7 remote alarm system and performing weekly door gasket inspections.

- If your primary focus is operational efficiency and cost: Focus on monthly condenser coil and filter cleaning to minimize energy consumption.

- If your primary focus is long-term reliability: Combine all practices and schedule an annual professional service to check compressors, fans, and cooling system health.

Ultimately, these consistent practices transform maintenance from a chore into your best insurance policy for sample security.

Summary Table:

| Maintenance Task | Key Action | Primary Benefit |

|---|---|---|

| Condenser Coils | Clean monthly | Prevents overheating, reduces energy costs |

| Door Gaskets | Inspect weekly for cracks/frost | Ensures a tight seal, maintains temperature stability |

| Internal Ice | Defrost per manufacturer's guidelines | Prevents insulation, frees up storage space |

| Temperature | Use a 24/7 remote monitoring system | Provides early warning of deviations to save samples |

Safeguard your critical samples with confidence. A well-maintained ULT freezer is your best insurance against costly sample loss and equipment failure. KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you implement a robust maintenance plan or provide reliable equipment to ensure your samples' long-term integrity.

Contact us today to discuss your ULT freezer needs and ensure your lab's success.

Visual Guide

Related Products

- 508L Advanced Vertical Ultra Low Temperature Freezer for Critical Laboratory Storage

- 408L Advanced Vertical Laboratory Ultra Low Temperature Freezer for Critical Research Material Preservation

- 58L Precision Laboratory Ultra Low Temperature Upright Freezer for Critical Sample Storage

- 808L Precision Laboratory Vertical Ultra Low Temperature Freezer

- 158L Precision Vertical Ultra Low Freezer for Laboratory Applications

People Also Ask

- What are the recommendations for storing mRNA vaccines in ultra-low temperature freezers? Ensure Absolute Stability at -80°C

- What is the purpose of ultra-low temperature (ULT) freezers? Preserve Critical Biological Samples

- What are the key features to look for in an ultra-low temperature freezer for mRNA vaccine storage? Essential Features for Absolute Vaccine Integrity

- Why are ULT freezers considered vital equipment in labs? Ensuring Uncompromised Sample Integrity for Critical Research

- What is the temperature control capability of ultra-low freezers? Precise Stability Down to -86°C