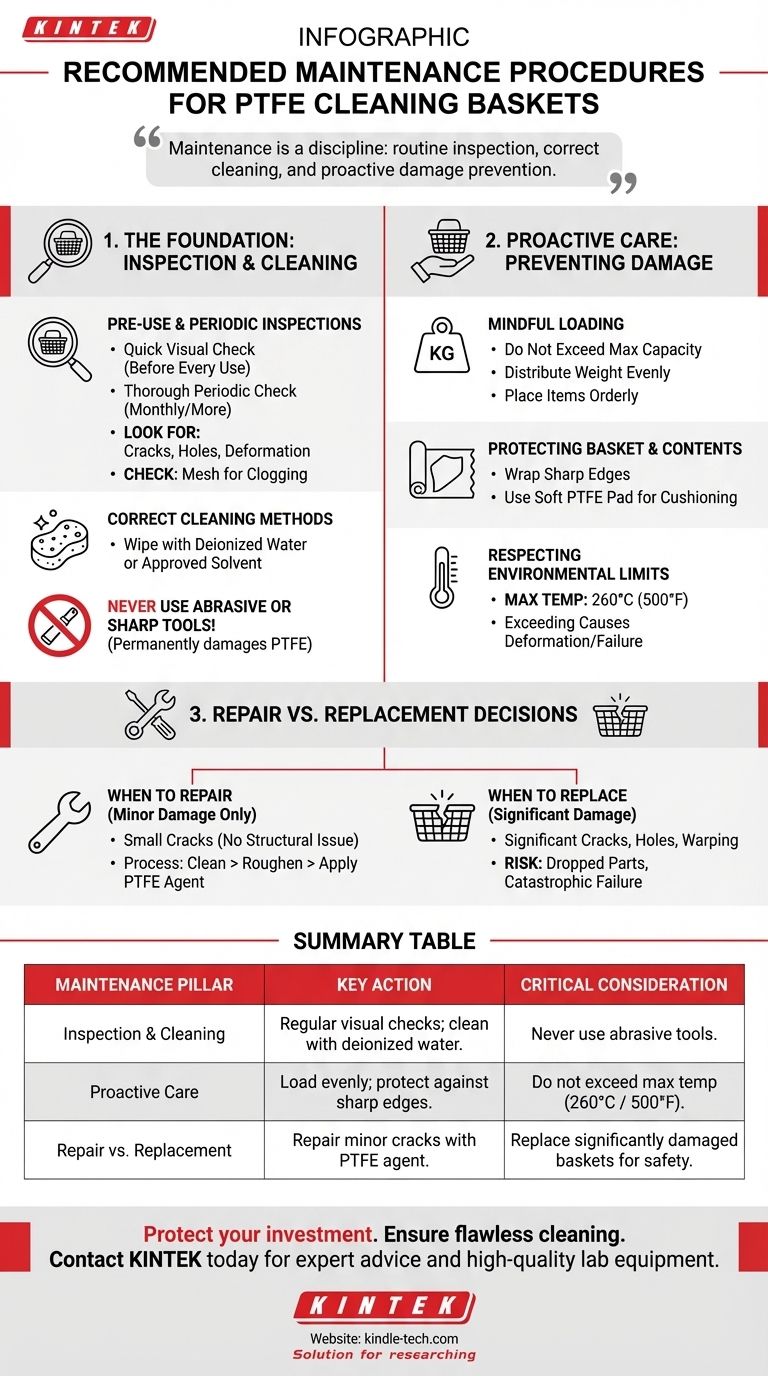

Proper maintenance of a PTFE basket is a discipline built on three core pillars: routine inspection, correct cleaning and handling, and proactive damage prevention. The goal is to preserve the basket's structural integrity and chemical inertness, ensuring it does not damage valuable parts or compromise the cleaning process.

Maintaining a Polytetrafluoroethylene (PTFE) cleaning basket is not just about cleaning the basket itself. It is a systematic process of inspection, careful handling, and environmental control designed to protect the integrity of your entire cleaning protocol and the high-value components you work with.

The Foundation: Inspection and Cleaning

Consistent inspection and proper cleaning are the first lines of defense in extending the life of a PTFE basket and ensuring its performance.

Pre-Use and Periodic Inspections

Before every use, conduct a quick visual check for obvious defects. This simple habit prevents process failures.

A more thorough inspection should be performed periodically—monthly for light use, or more frequently for heavy use. Look for cracks, holes, or any signs of deformation.

Also, carefully check the mesh for any clogging that could impede the flow of cleaning solutions. Ensure all components, such as the handle, are secure and stable.

Correct Cleaning Methods

The basket's non-stick, chemically inert surface simplifies cleaning. The recommended method is to wipe the surfaces with deionized water or a suitable, approved solvent.

It is critical to never use abrasive or sharp tools, such as steel wool or metal scrapers. These will permanently scratch and damage the PTFE surface, creating areas where contaminants can accumulate.

Proactive Care: Preventing Damage During Use

How you handle and load the basket has a direct impact on its longevity. Most damage is preventable through proper operational discipline.

Mindful Loading and Handling

Never exceed the basket's specified maximum load capacity. Overloading causes stress, leading to deformation and premature failure.

Distribute the weight of items evenly across the basket's base to avoid creating localized stress points.

Place items into the basket in an orderly fashion, leaving enough space between them for the cleaning solution to fully contact all surfaces.

Protecting the Basket and Its Contents

If you must clean items with sharp edges or corners, wrap them in a soft, compatible material before placing them in the basket to prevent scratches.

For highly fragile or precision parts, consider placing a soft PTFE pad at the bottom of the basket. This provides a crucial cushioning layer against impact damage during handling or processes like ultrasonic cleaning.

Respecting Environmental Limits

PTFE has a high-temperature tolerance, but it is not infinite. Do not use the basket in an environment that exceeds its maximum rated temperature, typically 260°C (500°F).

Exceeding this limit can cause permanent deformation, reduce its performance, and potentially damage the basket beyond repair.

Understanding the Trade-offs: Repair vs. Replacement

When damage does occur, you must make a critical decision between repairing the unit and replacing it entirely.

When to Repair Minor Damage

Small, minor cracks can sometimes be repaired. This is only suitable for damage that does not compromise the basket's structural integrity.

The repair process involves cleaning the damaged area, roughening the surface to create a mechanical bond, and applying a specialized PTFE repair agent according to the manufacturer's instructions.

When to Replace the Basket

Replacement is the only safe option if the basket has significant cracks, holes, or warping. A compromised basket risks dropping and damaging expensive parts or failing catastrophically during a cleaning cycle.

Using a damaged basket undermines the entire purpose of a controlled cleaning process, as it can no longer guarantee part safety or cleaning efficacy.

Making the Right Choice for Your Process

Your maintenance strategy should align with your operational priorities.

- If your primary focus is part safety and process purity: Emphasize rigorous pre-use inspections and immediately replace any basket with even moderate damage.

- If your primary focus is extending equipment lifespan: Prioritize correct handling, even load distribution, and prompt repair of minor surface-level defects.

- If your primary focus is consistent cleaning efficacy: Routinely inspect for and clear any clogged mesh, and during ultrasonic cleaning, ensure the basket's position is stable.

Ultimately, disciplined maintenance transforms your PTFE basket from a simple accessory into a reliable and long-lasting asset.

Summary Table:

| Maintenance Pillar | Key Action | Critical Consideration |

|---|---|---|

| Inspection & Cleaning | Regular visual checks for cracks/deformation; clean with deionized water. | Never use abrasive tools to avoid surface damage. |

| Proactive Care | Load evenly without exceeding capacity; protect against sharp edges. | Do not exceed max temperature (typically 260°C / 500°F). |

| Repair vs. Replacement | Repair minor cracks with a PTFE agent. | Replace baskets with significant damage to ensure safety. |

Protect your investment and ensure flawless cleaning results. Proper maintenance is key to maximizing the lifespan of your PTFE baskets and safeguarding your high-value components. KINTEK specializes in high-quality lab equipment and consumables, including durable PTFE cleaning baskets designed for demanding laboratory environments. Let our experts help you select the right equipment and establish best-practice maintenance routines. Contact us today to discuss your lab's specific needs!

Visual Guide

Related Products

- Custom Machined and Molded PTFE Teflon Parts Manufacturer for Laboratory ITO FTO Conductive Glass Cleaning Flower Basket

- Custom PTFE Teflon Parts Manufacturer Corrosion Resistant Cleaning Rack Flower Basket

- Custom PTFE Teflon Parts Manufacturer PTFE Beaker and Lids

- Custom PTFE Teflon Parts Manufacturer for Hollow Cleaning Basket and Rack Carrier

- Custom PTFE Teflon Parts Manufacturer for Three-Necked Round Bottom Flask

People Also Ask

- What are the analytical used in laboratory? Choose the Right Tool for Your Lab's Needs

- What is the correct way to place items into a PTFE cleaning basket? Master the Art of Perfect, Repeatable Cleaning

- What material is a PTFE cleaning basket made of? Unlocking Superior Chemical and Thermal Resistance

- What is the maximum operating temperature for a PTFE cleaning basket? Avoid Catastrophic Failure at 260°C

- What inspection should be performed on a PTFE cleaning basket before use? A 3-Step Protocol for Safe, Effective Cleaning