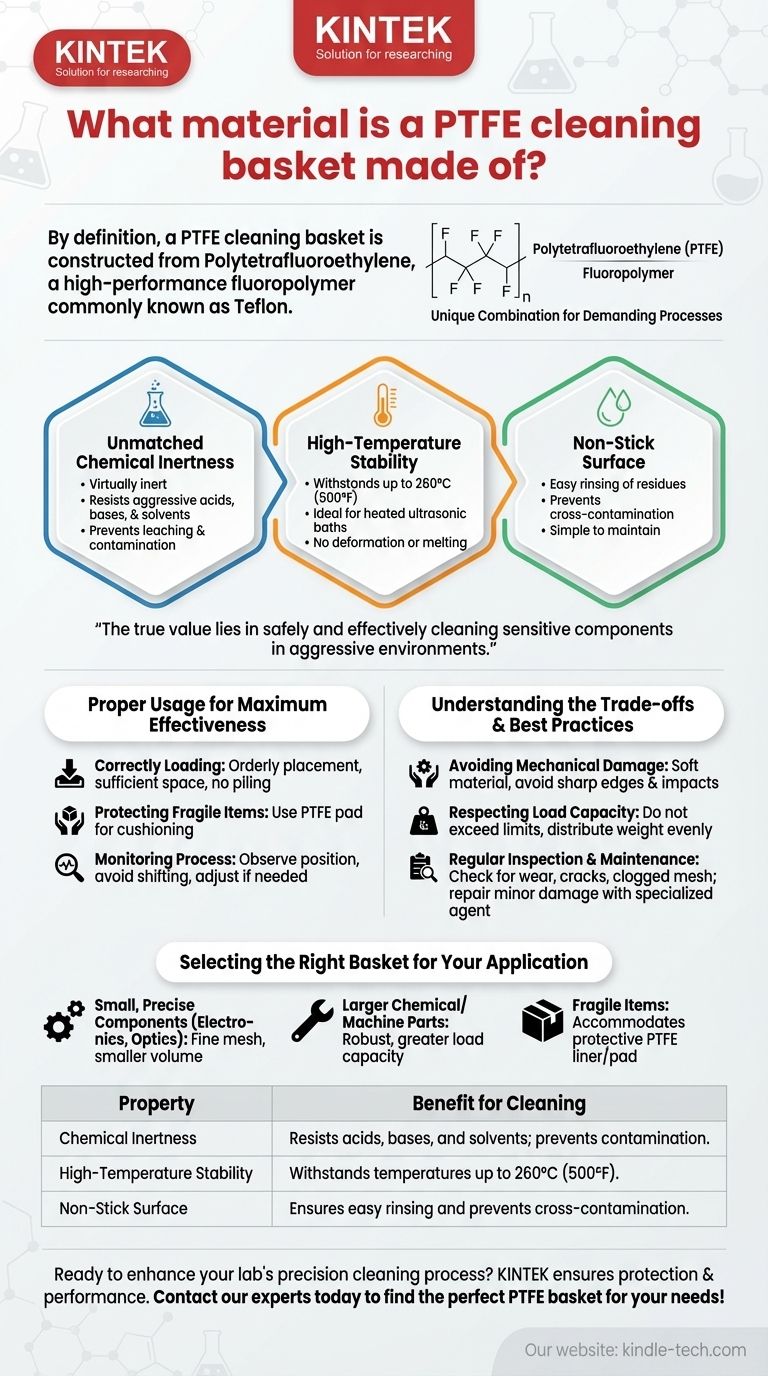

By definition, a PTFE cleaning basket is constructed from Polytetrafluoroethylene, a high-performance fluoropolymer commonly known by the brand name Teflon. This specific material choice is not arbitrary; it is selected for its unique combination of extreme chemical resistance, high-temperature tolerance, and non-stick surface properties, making it essential for demanding cleaning processes in laboratory, semiconductor, and industrial settings.

The true value of a PTFE basket lies not just in its material, but in how its unique properties solve a critical problem: safely and effectively cleaning sensitive or valuable components in aggressive chemical and thermal environments where nearly any other material would corrode, melt, or contaminate the parts.

Why PTFE is the Material of Choice

The selection of Polytetrafluoroethylene is a direct response to the harsh conditions of precision cleaning. Its molecular structure gives it a set of properties that are nearly ideal for this purpose.

Unmatched Chemical Inertness

PTFE is virtually inert and does not react with the vast majority of chemicals, including aggressive acids, bases, and solvents. This ensures the basket itself does not degrade or leach contaminants into the cleaning solution, preserving the purity of the process.

High-Temperature Stability

These baskets can withstand a wide range of temperatures, often up to 260°C (500°F). This allows them to be used in heated ultrasonic baths and other high-temperature cleaning or sterilization protocols without deforming or melting.

Non-Stick Surface

The famous non-stick quality of PTFE means that residues, particulates, and cleaning agents rinse off easily. This prevents cross-contamination between cleaning batches and makes the basket itself simple to maintain.

Proper Usage for Maximum Effectiveness

To leverage the benefits of a PTFE basket, proper handling and procedure are critical. The goal is to ensure the cleaning solution can effectively reach every surface without damaging the components inside.

Correctly Loading Components

Place items in an orderly fashion, leaving sufficient space between them. This allows the cleaning fluid to flow freely and make full contact. Avoid piling or overcrowding.

Protecting Fragile Items

For delicate or precision parts, place a soft PTFE pad at the bottom of the basket. This simple step cushions the items and protects them from impact damage or scratches during handling and agitated cleaning cycles.

Monitoring the Cleaning Process

During cleaning, especially in an ultrasonic bath, observe the basket's position. Vibrations can cause it to shift, which may reduce cleaning efficacy. If you notice any anomalies like basket deformation or shifting, pause the process and make adjustments.

Understanding the Trade-offs and Best Practices

While robust, PTFE is not indestructible. Understanding its limitations is key to ensuring a long service life and preventing costly damage to both the basket and the parts being cleaned.

Avoiding Mechanical Damage

PTFE is softer than metal and can be scratched or gouged. Avoid placing items with sharp edges directly into the basket without protection. Never drop the basket or subject it to severe impacts.

Respecting Load Capacity

Do not exceed the basket's specified maximum load capacity. Distribute the weight of the items as evenly as possible to prevent localized stress that can lead to warping or deformation over time.

Regular Inspection and Maintenance

Periodically inspect the basket for signs of wear, such as cracks, deep scratches, or clogged mesh. For heavy use, a monthly inspection is a good baseline.

Performing Minor Repairs

If you find minor cracks, they can often be repaired. After thoroughly cleaning the area and roughening the surface, apply a specialized PTFE repair agent according to the manufacturer's instructions to seal the damage.

Selecting the Right Basket for Your Application

Choosing the correct basket design is as important as the material itself. Your choice should be guided by the components you are cleaning and the equipment you are using.

- If your primary focus is small, precise components (e.g., electronics, optics): Choose a basket with a fine mesh and a smaller overall volume to prevent parts from falling through.

- If your primary focus is larger chemical or machine parts: Select a larger, more robust basket with a greater load-bearing capacity.

- If your primary focus is cleaning fragile items: Ensure you choose a basket that can accommodate a protective PTFE liner or pad at the bottom.

Ultimately, using a PTFE basket correctly is about leveraging its unique material strengths while respecting its physical limitations.

Summary Table:

| Property | Benefit for Cleaning |

|---|---|

| Chemical Inertness | Resists acids, bases, and solvents; prevents contamination. |

| High-Temperature Stability | Withstands temperatures up to 260°C (500°F). |

| Non-Stick Surface | Ensures easy rinsing and prevents cross-contamination. |

Ready to enhance your lab's precision cleaning process?

A PTFE cleaning basket from KINTEK ensures your sensitive components are protected from contamination and damage, even in the most aggressive chemical and thermal environments. Our lab equipment is designed for reliability and performance.

Contact our experts today to find the perfect PTFE basket for your specific laboratory needs!

Visual Guide

Related Products

- Custom PTFE Teflon Parts Manufacturer for Hollow Cleaning Basket and Rack Carrier

- Custom PTFE Teflon Parts Manufacturer Corrosion Resistant Cleaning Rack Flower Basket

- Custom Machined and Molded PTFE Teflon Parts Manufacturer for Laboratory ITO FTO Conductive Glass Cleaning Flower Basket

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

- Custom PTFE Teflon Parts Manufacturer for PTFE Buchner Funnel and Triangular Funnel

People Also Ask

- What are the common specifications and shapes for PTFE cleaning baskets? Maximize Chemical Purity & Process Integrity

- What is the correct way to place items into a PTFE cleaning basket? Master the Art of Perfect, Repeatable Cleaning

- How should a PTFE cleaning basket be cleaned and dried after use? Ensure Purity and Prevent Cross-Contamination

- How do Teflon (PTFE) baskets facilitate glass thin-film leaching? Enhance Accuracy with Chemical Inertness

- What is the maximum operating temperature for a PTFE cleaning basket? Avoid Catastrophic Failure at 260°C