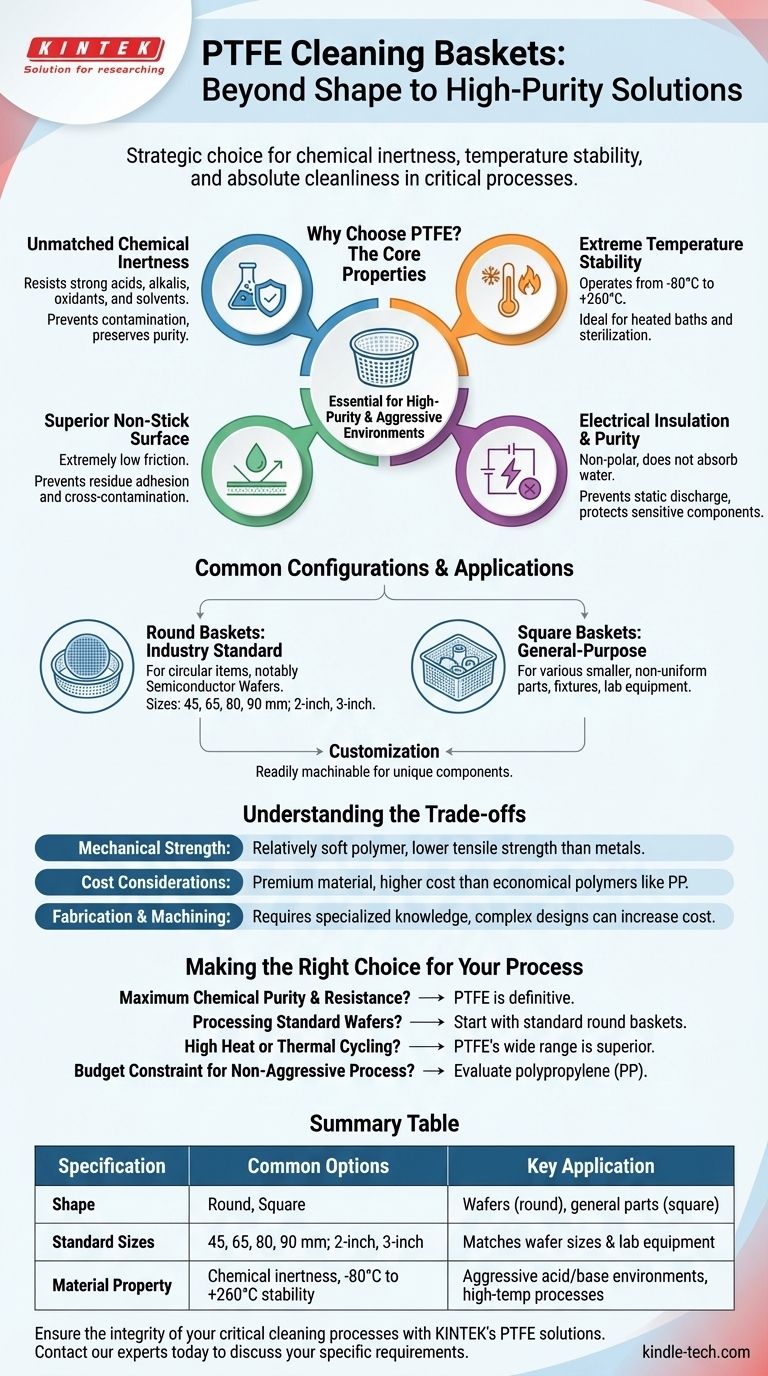

In short, PTFE cleaning baskets are typically manufactured in round or square shapes, with common standard sizes including 45, 65, 80, and 90 mm, as well as 2-inch and 3-inch diameters for wafer processing. However, the true value of these baskets lies not in their shape, but in the unique properties of the PTFE material itself, which make them essential for high-purity and aggressive chemical environments.

The decision to use a PTFE basket goes beyond simple dimensions. It is a strategic choice for processes where chemical inertness, extreme temperature stability, and absolute cleanliness are non-negotiable requirements.

Why Choose PTFE? The Core Properties Explained

The form factor of a basket is a secondary concern to the material it's made from. Polytetrafluoroethylene (PTFE) is a high-performance fluoropolymer chosen for its unparalleled resilience in demanding applications.

Unmatched Chemical Inertness

PTFE is virtually immune to chemical attack. It resists erosion from all strong acids, strong alkalis, potent oxidants, and organic solvents.

This means it will not degrade, leach contaminants, or react with the contents of your cleaning bath, preserving the purity of both the process and the parts being cleaned.

Extreme Temperature Stability

PTFE performs reliably across an exceptionally wide temperature range, remaining stable from -80°C to +260°C (-112°F to +500°F).

It can be used for extended periods at high temperatures without losing its physical properties, making it ideal for processes involving heated chemical baths or sterilization cycles.

Superior Non-Stick Surface

One of PTFE's most valuable characteristics is its extremely low coefficient of friction and non-adherent nature. In a cleaning application, this means two things.

First, contaminants and residues from the parts being cleaned will not stick to the basket itself. Second, the basket is exceptionally easy to clean, preventing cross-contamination between batches.

Electrical Insulation and Purity

PTFE is an outstanding electrical insulator because it is non-polar and does not absorb water. This is a critical feature in the semiconductor and electronics industries, where it prevents static discharge that could damage sensitive components during cleaning.

Common Configurations and Their Applications

While the material properties are primary, the physical shape and size are chosen to fit the specific process and components.

Standard Shapes: Round vs. Square

Round baskets are the industry standard for cleaning circular items, most notably semiconductor wafers. The dimensions (e.g., 2-inch, 3-inch) directly correspond to standard wafer sizes.

Square baskets are more of a general-purpose solution, well-suited for holding a variety of smaller, non-uniform parts, fixtures, or lab equipment.

The Role of Customization

Because PTFE is readily machinable, it can be fabricated into custom shapes and sizes. This is a key advantage when dealing with unique or delicate components that require a specialized holder to ensure proper cleaning, drainage, and security during the process.

Understanding the Trade-offs

No material is perfect for every situation. Being a trusted advisor means acknowledging the limitations of even a superior material like PTFE.

Mechanical Strength and Rigidity

PTFE is a relatively soft polymer. Compared to stainless steel or even other plastics like PEEK, it has lower tensile strength and can be susceptible to deformation under heavy loads, especially at elevated temperatures. It is not intended for high-stress structural applications.

Cost Considerations

PTFE is a premium, high-performance material, and its cost reflects that. For less demanding applications where chemical resistance or temperature range is not extreme, more economical polymers like polypropylene (PP) may be a sufficient and more cost-effective choice.

Fabrication and Machining

While customizable, machining PTFE requires specialized knowledge to manage its softness and thermal expansion. Complex custom designs can increase costs due to both material waste and the labor involved in fabrication.

Making the Right Choice for Your Process

Your choice should be guided by the specific demands of your application.

- If your primary focus is maximum chemical purity and resistance: PTFE is the definitive choice for aggressive acids (like hydrofluoric acid), bases, and solvents used in semiconductor or pharmaceutical work.

- If you are processing standard wafers: Start with standard round baskets (2-inch, 3-inch, etc.) that directly match your wafer dimensions for a secure fit.

- If your process involves high heat or thermal cycling: PTFE's wide operating temperature range makes it superior to less stable polymers that could warp or degrade.

- If budget is a primary constraint for a non-aggressive process: Objectively evaluate if a less expensive material like polypropylene can meet your chemical and thermal requirements.

By aligning the material's properties with your process needs, you can confidently select a basket that ensures the integrity and efficiency of your critical operations.

Summary Table:

| Specification | Common Options | Key Application |

|---|---|---|

| Shape | Round, Square | Wafers (round), general parts (square) |

| Standard Sizes | 45, 65, 80, 90 mm; 2-inch, 3-inch | Matches wafer sizes and lab equipment |

| Material Property | Chemical inertness, -80°C to +260°C stability | Aggressive acid/base environments, high-temperature processes |

Ensure the integrity of your critical cleaning processes with KINTEK's PTFE solutions.

As a specialist in high-purity lab equipment, KINTEK provides PTFE cleaning baskets that deliver unmatched chemical resistance and thermal stability for semiconductor, pharmaceutical, and research applications. Our baskets are designed to prevent contamination, withstand aggressive chemicals, and maintain performance under extreme temperatures.

Ready to enhance your lab's efficiency and purity? Contact our experts today to discuss your specific requirements and discover how our PTFE baskets can optimize your workflow.

Visual Guide

Related Products

- Custom PTFE Teflon Parts Manufacturer Corrosion Resistant Cleaning Rack Flower Basket

- Custom PTFE Teflon Parts Manufacturer for Hollow Cleaning Basket and Rack Carrier

- Custom Machined and Molded PTFE Teflon Parts Manufacturer for Laboratory ITO FTO Conductive Glass Cleaning Flower Basket

- Custom PTFE Teflon Parts Manufacturer for Hollow Etching Flower Basket ITO FTO Developing Glue Removal

- Custom PTFE Teflon Parts Manufacturer for PTFE Measuring Cylinder 10/50/100ml

People Also Ask

- What precautions should be taken regarding the physical handling and loading of a PTFE cleaning basket? Prevent Damage and Ensure Process Integrity

- What should be monitored during the cleaning process when using a PTFE cleaning basket? Ensure Reliable Results & Prevent Damage

- What is the procedure for using a PTFE cleaning basket? A 3-Step Guide for Flawless Results

- What is the correct way to place items into a PTFE cleaning basket? Master the Art of Perfect, Repeatable Cleaning

- What is the maximum operating temperature for a PTFE cleaning basket? Avoid Catastrophic Failure at 260°C