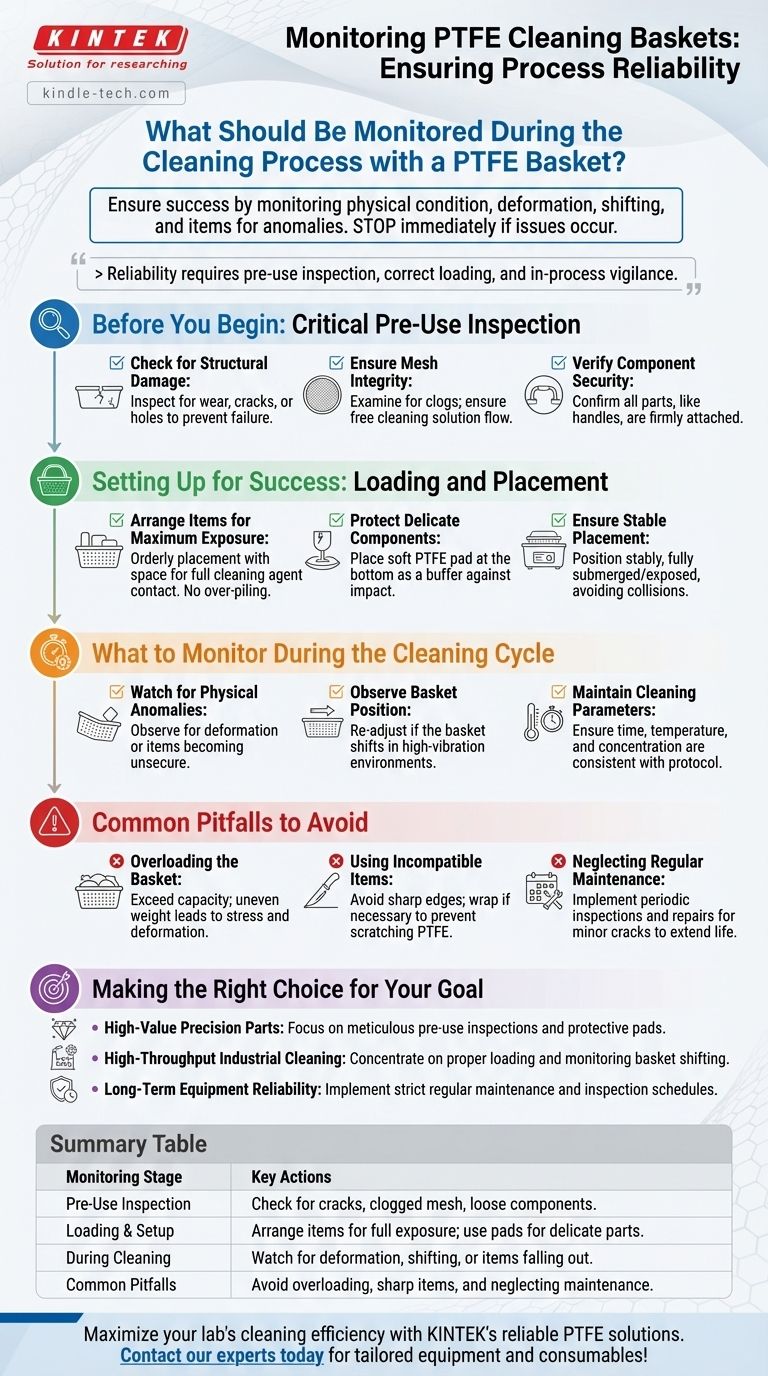

To ensure a successful cleaning process, you must monitor the physical condition of the PTFE basket and the items within it for any anomalies. This includes watching for basket deformation, shifting positions (especially during ultrasonic cleaning), or any signs that the items are falling out. If any of these issues occur, the process must be stopped immediately for correction.

The reliability of a cleaning process using a PTFE basket extends beyond the cycle itself. It requires a systematic approach encompassing pre-use inspection, correct loading, and in-process vigilance to prevent part damage and ensure consistent, effective results.

Before You Begin: The Critical Pre-Use Inspection

The integrity of your entire cleaning process starts with a healthy basket. A quick check before each use can prevent costly failures.

Check for Structural Damage

Carefully inspect the basket for any signs of wear and tear, such as cracks or holes. A compromised structure can fail mid-process, potentially damaging valuable components.

Ensure Mesh Integrity

Examine the mesh to ensure it is not clogged with residue from previous cycles. Clogged mesh can impede the flow of the cleaning solution and compromise cleaning effectiveness.

Verify Component Security

Confirm that all parts of the basket, such as the handle, are securely attached. A loose component could detach during cleaning, disrupting the process.

Setting Up for Success: Loading and Placement

How you load and position the basket is just as important as the cleaning parameters themselves. Proper setup guarantees optimal exposure to the cleaning agent.

Arrange Items for Maximum Exposure

Place items in an orderly fashion, leaving sufficient space between them. This allows the cleaning solution to make full and even contact with all surfaces. Avoid over-piling.

Protect Delicate Components

For fragile or precision parts, place a soft PTFE pad at the bottom of the basket. This simple step provides a crucial buffer against impact damage during the cleaning cycle.

Ensure Stable Placement in Equipment

Position the basket stably inside the cleaning equipment, such as an ultrasonic cleaner. Ensure it is either fully submerged or fully exposed to the spray, depending on your method, and avoid forceful collisions with the equipment walls.

What to Monitor During the Cleaning Cycle

Vigilance during the cleaning process allows you to catch and correct issues before they compromise the outcome.

Watch for Physical Anomalies

Closely observe the basket for any signs of deformation. Also, ensure that the items remain securely within the basket throughout the cycle.

Observe Basket Position

In high-vibration environments like ultrasonic cleaning, baskets can shift. If you notice the basket has moved, it should be readjusted to maintain cleaning efficacy.

Maintain Cleaning Parameters

While observing the basket, always ensure the established cleaning parameters—such as time, temperature, and solution concentration—are being maintained as required by your protocol.

Common Pitfalls to Avoid

Understanding the limitations and common failure points of PTFE baskets is key to extending their life and ensuring process reliability.

Overloading the Basket

Never exceed the basket's specified maximum load capacity. Distribute the weight of the items evenly to avoid creating localized stress that can lead to deformation.

Using Incompatible Items

Avoid placing items with sharp edges or corners directly into the basket. If necessary, wrap them in a soft material first to prevent scratching or puncturing the PTFE surface.

Neglecting Regular Maintenance

Implement a schedule for periodic inspections, such as monthly checks. If minor cracks are found, they can often be repaired with a specialized PTFE repair agent, extending the basket's service life.

Making the Right Choice for Your Goal

Your monitoring strategy should align with the specific demands of your cleaning application.

- If your primary focus is cleaning high-value precision parts: Prioritize meticulous pre-use inspections and the use of protective PTFE pads to prevent any possibility of damage.

- If your primary focus is high-throughput industrial cleaning: Concentrate on proper loading to avoid overloading and closely monitor for basket shifting during the cycle.

- If your primary focus is ensuring long-term equipment reliability: Implement a strict regular maintenance and inspection schedule to catch and repair minor damage before it leads to failure.

A systematic approach to handling and monitoring transforms a simple basket into a highly reliable tool for your critical cleaning operations.

Summary Table:

| Monitoring Stage | Key Actions |

|---|---|

| Pre-Use Inspection | Check for cracks, clogged mesh, and loose components. |

| Loading & Setup | Arrange items for full exposure; use pads for delicate parts. |

| During Cleaning | Watch for deformation, shifting, or items falling out. |

| Common Pitfalls | Avoid overloading, sharp items, and neglecting maintenance. |

Maximize your lab's cleaning efficiency and protect valuable components with KINTEK's reliable PTFE solutions. Our PTFE cleaning baskets are designed for durability and precision, ensuring consistent results for your high-value or high-throughput applications. Contact our experts today to find the perfect lab equipment and consumables tailored to your specific needs!

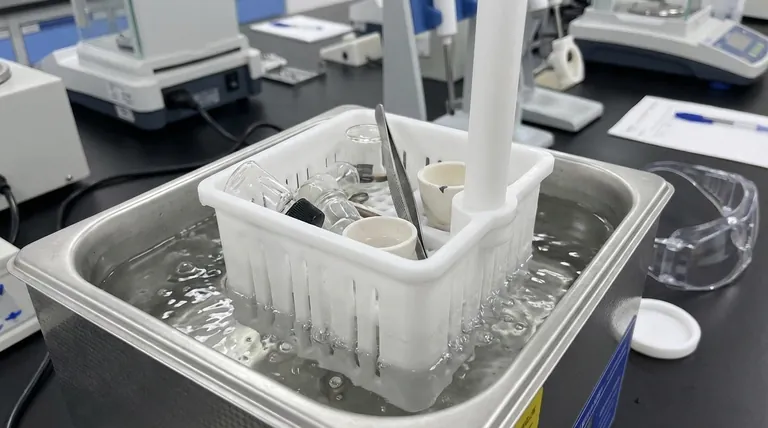

Visual Guide

Related Products

- Custom PTFE Teflon Parts Manufacturer Corrosion Resistant Cleaning Rack Flower Basket

- Custom PTFE Teflon Parts Manufacturer for Hollow Cleaning Basket and Rack Carrier

- Custom Machined and Molded PTFE Teflon Parts Manufacturer for Laboratory ITO FTO Conductive Glass Cleaning Flower Basket

- Custom PTFE Teflon Parts Manufacturer for Conductive Glass Substrate Cleaning Rack

- Custom PTFE Teflon Parts Manufacturer for Centrifuge Tube Racks

People Also Ask

- How should a PTFE cleaning basket be stored when not in use? Maximize Lifespan & Prevent Contamination

- What is the maximum operating temperature for a PTFE cleaning basket? Avoid Catastrophic Failure at 260°C

- What material is a PTFE cleaning basket made of? Unlocking Superior Chemical and Thermal Resistance

- What precautions should be taken regarding the physical handling and loading of a PTFE cleaning basket? Prevent Damage and Ensure Process Integrity

- What is the correct way to place items into a PTFE cleaning basket? Master the Art of Perfect, Repeatable Cleaning