Proper handling and loading of a PTFE basket requires a focus on preventing physical damage and ensuring process effectiveness. The core precautions are to avoid impacts, never exceed the basket's load capacity, distribute weight evenly, and protect the basket's surface from scratches by wrapping any items with sharp edges.

The central challenge with PTFE baskets is balancing their exceptional chemical resistance with their relative softness as a material. Your handling protocol must therefore be designed to prevent physical stress—from impact, sharp points, or uneven loading—to protect both the basket's structural integrity and the sensitive components it holds.

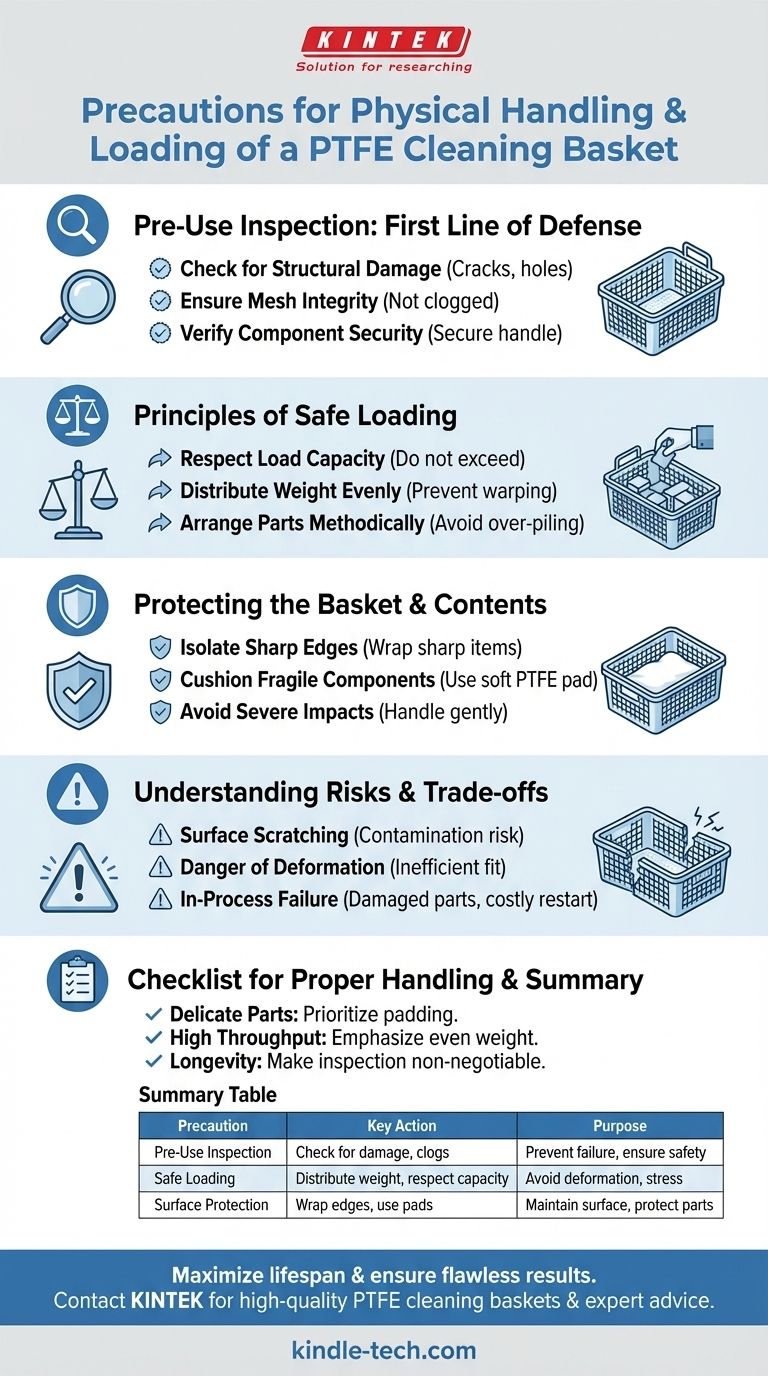

The Pre-Use Inspection: Your First Line of Defense

Before any items are loaded, a quick but thorough inspection is the most effective way to prevent failures during the cleaning process. A compromised basket risks damaging parts and can ruin an entire cleaning batch.

Check for Structural Damage

Carefully examine the basket for any visible cracks, fractures, or holes. Any breach in the structure can worsen under load or during cleaning, potentially causing parts to fall out.

Ensure Mesh Integrity

Inspect the mesh openings to ensure they are not clogged with residue from previous cycles. Blocked mesh restricts the flow of cleaning solutions, leading to inconsistent and ineffective results.

Verify Component Security

Confirm that attachments like the handle are secure and fully intact. A failing handle presents a significant safety risk when moving a loaded basket, especially one filled with expensive components.

Principles of Safe Loading

How you place items into the basket is just as important as how you handle the basket itself. The goal is to create a stable, well-balanced load that allows the cleaning solution to work effectively.

Respect the Load Capacity

Every basket has a maximum load capacity. Exceeding this limit is the primary cause of deformation and structural failure. Always adhere to the manufacturer's specified weight limit.

Distribute Weight Evenly

Avoid concentrating heavy items in one area. By distributing the weight evenly across the bottom of the basket, you prevent localized stress that can lead to warping or cracking over time.

Arrange Parts Methodically

Place items in an orderly fashion, ensuring there is adequate space between them. This allows the cleaning solution to make full contact with all surfaces, which is critical for a successful cleaning cycle. Avoid over-piling components.

Protecting the Basket and Its Contents

PTFE is a relatively soft material. Protecting its surface is crucial for maintaining its non-reactive properties and preventing damage to the delicate parts being cleaned.

Isolate Sharp Edges

Never place items with sharp edges or corners directly into the basket. These can easily scratch or gouge the PTFE surface. Wrap these sharp areas in a soft, compatible material before loading.

Cushion Fragile Components

For highly delicate or precision parts, place a soft PTFE pad at the bottom of the basket. This provides a crucial layer of cushioning that protects them from impact damage as the basket is moved.

Avoid Severe Impacts

Always handle the basket gently. Avoid dropping, striking, or subjecting it to severe pressure during handling, use, or storage. Remember that PTFE is not as impact-resistant as metal.

Understanding the Risks and Trade-offs

Failing to follow proper handling procedures introduces risks that can compromise both your equipment and your process outcomes.

The Risk of Surface Scratching

A key benefit of PTFE is its inert, non-stick surface. Scratches and gouges compromise this surface, creating areas where contaminants can cling and potentially cross-contaminate future batches.

The Danger of Deformation

Uneven loading or exceeding the weight limit can cause the basket to permanently deform. A warped basket may not fit correctly within the cleaning system, leading to inefficient processing or further damage.

In-Process Failure

If a damaged basket fails mid-cycle, the consequences can be severe. This can range from valuable parts falling out and being damaged to a complete disruption of the cleaning protocol, requiring a costly and time-consuming restart.

A Checklist for Proper Basket Handling

Apply these guidelines to ensure the longevity of your equipment and the consistency of your results.

- If your primary focus is cleaning delicate, high-value parts: Prioritize using a protective PTFE pad and ensuring no parts are touching to prevent any risk of impact damage.

- If your primary focus is maximizing throughput: Emphasize even weight distribution and strict adherence to the maximum load to prevent basket damage during high-volume use.

- If your primary focus is basket longevity and cost-control: Make the pre-use visual inspection a non-negotiable step in your standard operating procedure before every single use.

Ultimately, treating your PTFE basket with methodical care is a direct investment in the quality and reliability of your cleaning process.

Summary Table:

| Precaution | Key Action | Purpose |

|---|---|---|

| Pre-Use Inspection | Check for cracks, clogged mesh, and secure handles. | Prevent in-process failure and ensure safety. |

| Safe Loading | Distribute weight evenly and respect load capacity. | Avoid deformation and structural stress. |

| Surface Protection | Wrap sharp edges and use PTFE pads for cushioning. | Maintain non-reactive surface and protect delicate parts. |

Maximize the lifespan of your PTFE baskets and ensure flawless cleaning results. At KINTEK, we specialize in high-quality lab equipment and consumables, including durable PTFE cleaning baskets designed for precision and chemical resistance. Our experts can help you select the right equipment and develop best practices for your specific laboratory needs. Contact us today to learn how we can support your lab's efficiency and reliability!

Visual Guide

Related Products

- Custom PTFE Teflon Parts Manufacturer Corrosion Resistant Cleaning Rack Flower Basket

- Custom PTFE Teflon Parts Manufacturer for Hollow Cleaning Basket and Rack Carrier

- Custom Machined and Molded PTFE Teflon Parts Manufacturer for Laboratory ITO FTO Conductive Glass Cleaning Flower Basket

- Custom PTFE Teflon Parts Manufacturer for Hollow Etching Flower Basket ITO FTO Developing Glue Removal

- Custom PTFE Teflon Parts Manufacturer for Centrifuge Tube Racks

People Also Ask

- What is the procedure for using a PTFE cleaning basket? A 3-Step Guide for Flawless Results

- How should a PTFE cleaning basket be cleaned before its initial use? A Critical First Step for Process Integrity

- What are the common specifications and shapes for PTFE cleaning baskets? Maximize Chemical Purity & Process Integrity

- What material is a PTFE cleaning basket made of? Unlocking Superior Chemical and Thermal Resistance

- What is the correct way to place items into a PTFE cleaning basket? Master the Art of Perfect, Repeatable Cleaning