To properly clean a new PTFE cleaning basket, you must go beyond a simple water rinse. The correct procedure involves soaking the basket in a neutral detergent solution to remove any residual contaminants from the manufacturing process, followed by a thorough rinsing to ensure no detergent is left behind.

The core principle is decontamination, not just surface cleaning. A new basket can carry invisible residues like mold-release agents or oils from manufacturing, which can compromise the integrity of highly sensitive cleaning processes if not properly removed before its first use.

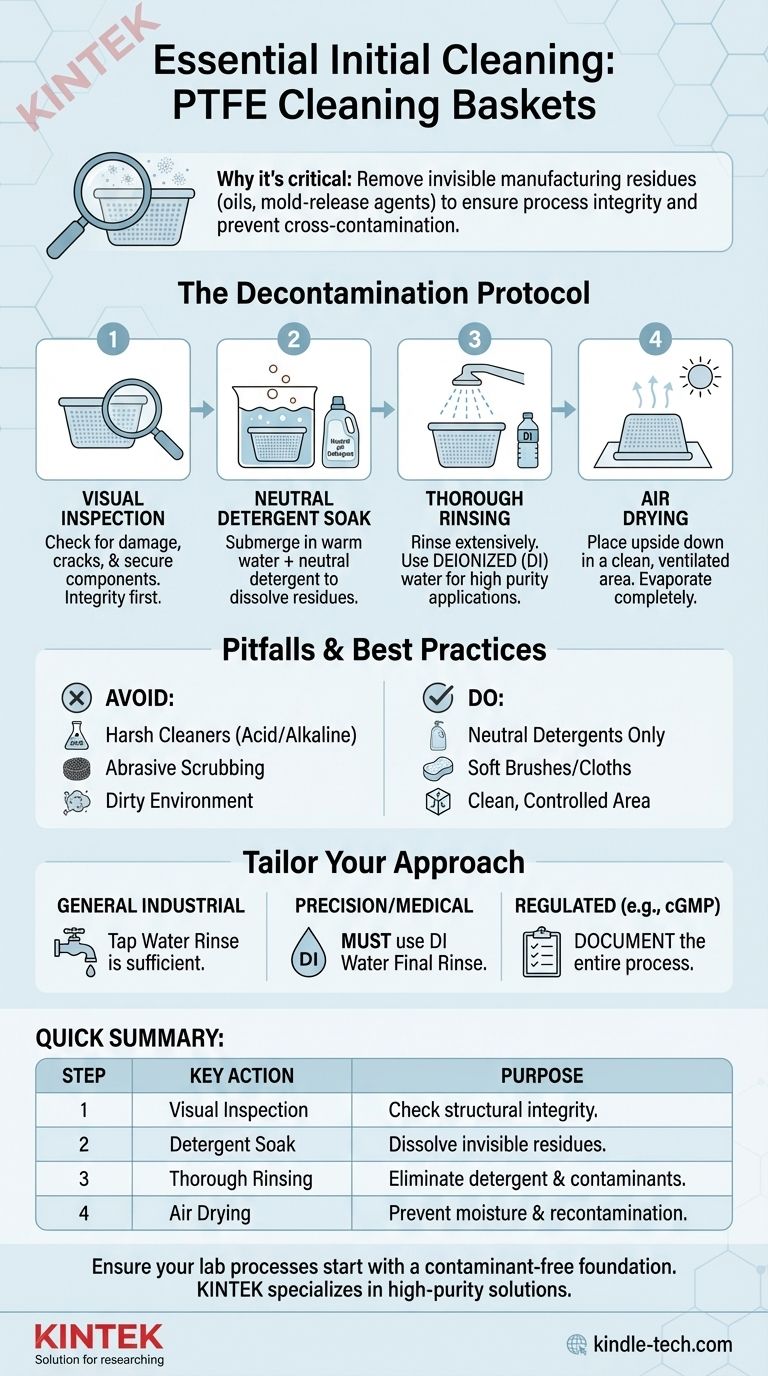

Why Initial Cleaning is a Critical First Step

A new piece of equipment introduced into a controlled environment must be treated as a potential source of contamination until it is properly prepared. The initial cleaning of a PTFE basket is a foundational step in ensuring process reliability.

Beyond Surface Dust

A quick rinse may remove visible dust from storage or shipping, but it fails to address microscopic films or particulates embedded in the material's surface from production.

Eliminating Manufacturing Residues

The manufacturing of PTFE products can involve agents and oils that are not visible to the naked eye. These substances can leach into your cleaning solutions, cross-contaminating the critical parts you intend to clean.

Ensuring Process Integrity

By properly preparing your basket, you establish it as a neutral and passive tool. This guarantees that any results from your cleaning process are due to your validated procedure, not an unknown variable introduced by the equipment itself.

The Definitive Pre-Use Protocol

Follow these steps methodically to ensure your new PTFE basket is fully prepared and free of contaminants before it enters your workflow.

Step 1: Meticulous Visual Inspection

Before any cleaning, carefully examine the entire basket. Check for any cracks, holes, or damage to the mesh. Confirm that the handle and all components are secure. A damaged basket can fail during use, potentially losing or damaging valuable parts.

Step 2: The Decontamination Soak

Submerge the basket completely in a solution of warm water and a neutral pH detergent. Allow it to soak for a period, which helps to dissolve and lift any residual oils or manufacturing agents from the PTFE surfaces.

Step 3: Thorough Final Rinsing

Remove the basket from the detergent solution and rinse it extensively with clean water. For high-purity applications, such as in electronics or medical device manufacturing, a final rinse with deionized (DI) water is highly recommended to prevent mineral deposits.

Step 4: Proper Air Drying

Once thoroughly rinsed, place the basket upside down in a clean, dry, and well-ventilated area. This allows all moisture to drain and evaporate completely, preventing the growth of bacteria or the reintroduction of airborne contaminants.

Common Pitfalls and Best Practices

Avoiding common mistakes during this initial phase is just as important as the cleaning steps themselves. A misstep here can compromise the basket's integrity for its entire service life.

Using the Wrong Cleaners

Never use abrasive, acidic, or alkaline cleaners on PTFE. These harsh chemicals can damage the non-stick surface, creating micro-scratches that trap contaminants and become impossible to clean effectively later on. Stick strictly to neutral detergents.

Damaging the Surface

During cleaning, use only soft brushes or cloths if any manual scrubbing is needed. Hard-bristled brushes or abrasive pads will permanently scratch the PTFE, degrading its performance and cleanliness.

Neglecting the Environment

Perform the initial cleaning in a clean environment. Cleaning a basket in a dirty or dusty area will simply re-contaminate it, defeating the entire purpose of the preparation protocol.

Making the Right Choice for Your Goal

Your specific application determines the level of rigor required. Tailor your initial preparation protocol to match the sensitivity of your process.

- If your primary focus is general industrial parts: A thorough soak in neutral detergent followed by a complete tap water rinse is typically sufficient.

- If your primary focus is precision electronics or medical components: You must use a final rinse with deionized (DI) water to eliminate any possibility of mineral spotting or ionic contamination.

- If your primary focus is working in a regulated (e.g., cGMP) environment: You should document the entire initial inspection and cleaning process as part of your formal equipment qualification procedure.

Properly preparing your tools from the very beginning is the first step toward achieving consistent and reliable results.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1 | Visual Inspection | Check for damage and ensure structural integrity. |

| 2 | Neutral Detergent Soak | Dissolve and remove invisible manufacturing residues. |

| 3 | Thorough Rinsing | Eliminate detergent and contaminants; use DI water for sensitive applications. |

| 4 | Air Drying | Prevent moisture-related contamination in a clean environment. |

Ensure your lab processes start with a contaminant-free foundation. The correct initial cleaning of your PTFE baskets is critical for reliable results in electronics, medical device, and pharmaceutical manufacturing. KINTEK specializes in high-purity lab equipment and consumables designed for demanding environments. Contact our experts today to discuss your specific application needs and ensure your equipment meets the highest standards of cleanliness from day one.

Visual Guide

Related Products

- Custom PTFE Teflon Parts Manufacturer Corrosion Resistant Cleaning Rack Flower Basket

- Custom PTFE Teflon Parts Manufacturer for Hollow Cleaning Basket and Rack Carrier

- Custom Machined and Molded PTFE Teflon Parts Manufacturer for Laboratory ITO FTO Conductive Glass Cleaning Flower Basket

- Custom PTFE Teflon Parts Manufacturer for Centrifuge Tube Racks

- Custom PTFE Teflon Parts Manufacturer for Hollow Etching Flower Basket ITO FTO Developing Glue Removal

People Also Ask

- What precautions should be taken regarding the physical handling and loading of a PTFE cleaning basket? Prevent Damage and Ensure Process Integrity

- What material is a PTFE cleaning basket made of? Unlocking Superior Chemical and Thermal Resistance

- What are the common specifications and shapes for PTFE cleaning baskets? Maximize Chemical Purity & Process Integrity

- What is the procedure for using a PTFE cleaning basket? A 3-Step Guide for Flawless Results

- How should a PTFE cleaning basket be stored when not in use? Maximize Lifespan & Prevent Contamination