The correct way to place items into a PTFE cleaning basket is to arrange them in an orderly fashion, ensuring there is ample space between each part. This method prevents over-piling and allows the cleaning solution to make full, unimpeded contact with all surfaces, which is critical for achieving a thorough and uniform clean.

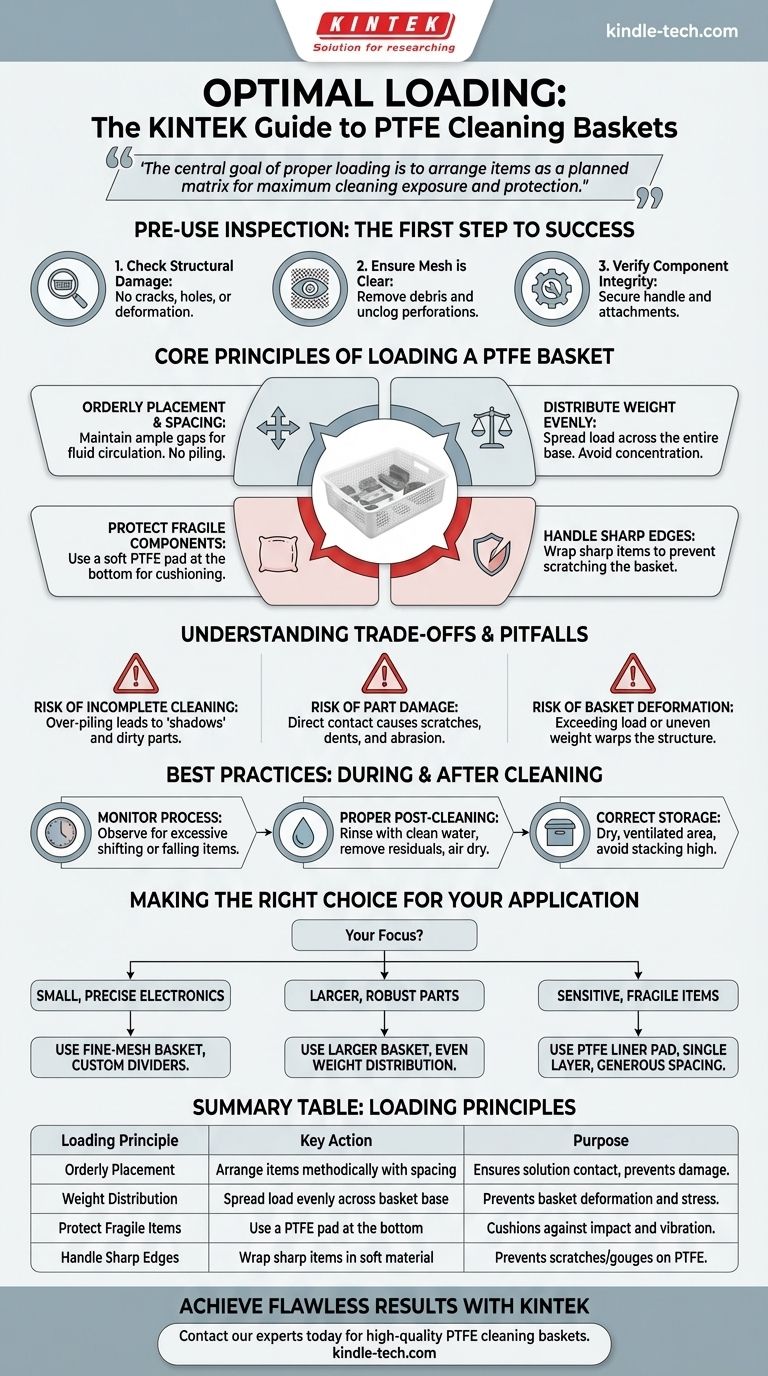

The central goal of proper loading is not merely to fit items into a basket, but to arrange them as a planned matrix. This ensures maximum exposure to the cleaning agent while actively preventing damage to both the delicate parts and the basket itself.

Pre-Use Inspection: The First Step to Success

Before any items are loaded, a quick but thorough inspection of the basket is a critical step that prevents process failure and component loss.

Check for Structural Damage

Carefully examine the basket for any cracks, holes, or significant deformation. A compromised structure can fail during the cleaning process, potentially dropping and damaging valuable parts.

Ensure the Mesh is Clear

Visually inspect the basket's mesh to ensure it is not clogged with debris from previous cycles. Blocked perforations can impede the flow of the cleaning solution, creating "shadows" where parts are not properly cleaned.

Verify Component Integrity

Confirm that the handle and any other components are securely attached. A failure here, especially during transfer, can be a safety hazard and lead to dropped parts.

The Core Principles of Loading a PTFE Basket

Proper loading is a function of discipline and technique. Following these principles ensures consistent, high-quality cleaning results.

Ensure Orderly Placement and Spacing

Arrange items methodically, never just piling them in. The key is to maintain a gap between each component, allowing liquids and ultrasonic waves to circulate freely.

Distribute Weight Evenly

Spread the load across the entire base of the basket. Concentrating weight in one area can cause localized stress and lead to basket deformation over time.

Protect Fragile Components

For delicate or precision parts, place a soft PTFE pad at the bottom of the basket. This simple step provides a cushion against impact and vibration during the cleaning cycle.

Handle Sharp Edges

If you must clean items with sharp edges or corners, wrap them in a soft, compatible material. This prevents them from scratching or gouging the basket's PTFE surface.

Understanding the Trade-offs and Pitfalls

Ignoring proper loading procedures introduces significant risks that can compromise your entire cleaning protocol.

Risk of Incomplete Cleaning

The most immediate consequence of over-piling is inconsistent cleaning. Parts in the middle of a pile will not receive adequate exposure to the cleaning agent, emerging dirty or contaminated.

Risk of Part Damage

When parts are in direct contact, they can scratch, dent, or abrade each other during agitated cleaning processes like ultrasonics. This is especially true for precision-machined surfaces or delicate electronics.

Risk of Basket Deformation

Exceeding the basket's maximum load capacity or concentrating weight unevenly can cause permanent warping or damage. This not only shortens the life of the basket but can also affect its stability within the cleaning tank.

Best Practices During and After Cleaning

The process does not end once the basket is loaded. Vigilance during and after the cycle is essential for maintaining equipment and ensuring quality.

Monitor the Cleaning Process

Observe the basket during operation. If you notice it shifting excessively due to vibration or see items falling out of place, stop the process immediately to make adjustments.

Proper Post-Cleaning Procedure

After the cycle, promptly rinse the basket with clean water to remove residual cleaning solution. Use a soft brush and neutral detergent for stubborn stains, then allow it to air dry completely to prevent bacterial growth.

Correct Storage Conditions

When not in use, store the basket in a dry, ventilated area away from direct sunlight or high temperatures. Avoid stacking baskets too high, as the weight can cause the ones at the bottom to deform.

Making the Right Choice for Your Application

Your loading strategy should adapt to the specific items you are cleaning.

- If your primary focus is cleaning small, precise electronic components: Use a fine-mesh basket and consider custom inserts or dividers to keep each component isolated and secure.

- If your primary focus is cleaning larger, robust chemical or mechanical parts: Use a larger basket with a greater load-bearing capacity, focusing on even weight distribution and stable placement.

- If your primary focus is protecting highly sensitive or fragile items: Always use a PTFE liner pad and arrange parts in a single layer with generous spacing, even if it means running more cycles.

Ultimately, treating the basket as a precision tool is the key to achieving perfect, repeatable cleaning results.

Summary Table:

| Loading Principle | Key Action | Purpose |

|---|---|---|

| Orderly Placement | Arrange items methodically with spacing | Ensures solution contact and prevents damage |

| Weight Distribution | Spread load evenly across the basket base | Prevents basket deformation and stress |

| Protect Fragile Items | Use a PTFE pad at the bottom | Cushions against impact and vibration |

| Handle Sharp Edges | Wrap sharp items in a soft material | Prevents scratches and gouges on the PTFE |

Achieve flawless, laboratory-grade cleaning results every time. Proper technique is essential, but so is having the right equipment. KINTEK specializes in high-quality PTFE cleaning baskets and lab consumables designed for precision and durability.

Contact our experts today to find the perfect cleaning solution for your specific application, whether you're handling delicate electronics, robust mechanical parts, or sensitive components. Let us help you optimize your process for perfect, repeatable results.

Visual Guide

Related Products

- Custom PTFE Teflon Parts Manufacturer Corrosion Resistant Cleaning Rack Flower Basket

- Custom PTFE Teflon Parts Manufacturer for Hollow Cleaning Basket and Rack Carrier

- Custom Machined and Molded PTFE Teflon Parts Manufacturer for Laboratory ITO FTO Conductive Glass Cleaning Flower Basket

- Custom PTFE Teflon Parts Manufacturer for Conductive Glass Substrate Cleaning Rack

- Custom PTFE Wafer Holders for Lab and Semiconductor Processing

People Also Ask

- What inspection should be performed on a PTFE cleaning basket before use? A 3-Step Protocol for Safe, Effective Cleaning

- What are the common specifications and shapes for PTFE cleaning baskets? Maximize Chemical Purity & Process Integrity

- What precautions should be taken regarding the physical handling and loading of a PTFE cleaning basket? Prevent Damage and Ensure Process Integrity

- What should be monitored during the cleaning process when using a PTFE cleaning basket? Ensure Reliable Results & Prevent Damage

- How should a PTFE cleaning basket be stored when not in use? Maximize Lifespan & Prevent Contamination