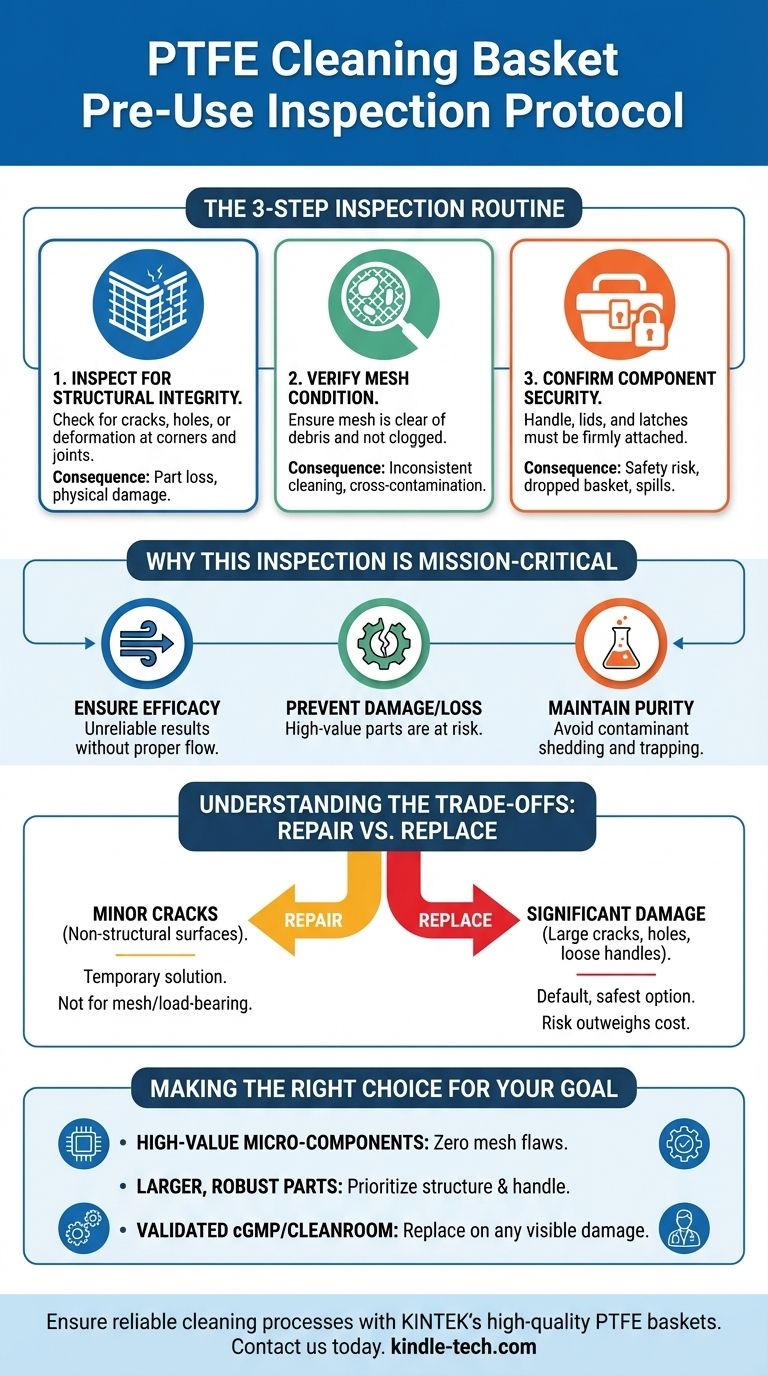

Before every use, a PTFE cleaning basket must undergo a systematic visual and physical inspection. You are primarily checking for any structural damage like cracks or holes, ensuring the mesh is not clogged or blocked, and verifying that all components, such as the handle, are securely attached. Finding any one of these issues may require the basket to be repaired or replaced to ensure a safe and effective cleaning cycle.

A pre-use inspection is not merely a check for damage; it is a critical control point to guarantee process effectiveness, prevent cross-contamination, and protect high-value components from being damaged or lost.

The Pre-Use Inspection Protocol

A consistent inspection routine is the foundation of a reliable cleaning process. It can be broken down into three simple, yet critical, steps to be performed before every cycle.

Inspect for Structural Integrity

Your first check should be for any visible cracks, holes, or deformation. Pay close attention to corners and joints where stress is concentrated.

A crack or hole can allow small, valuable parts to fall out and be lost. It can also snag delicate components, causing scratches or other physical damage.

Verify Mesh Condition

Examine the basket's mesh to ensure it is clear of debris and not clogged. Contaminants from a previous cleaning cycle can become trapped, leading to cross-contamination.

A clogged mesh also impedes the flow of the cleaning solution, creating "shadows" where parts are not cleaned effectively and resulting in an inconsistent or failed batch.

Confirm Component Security

Physically check that the handle is firmly attached and that any lids, latches, or other moving parts are secure and function correctly.

A loose handle presents a significant safety risk, potentially leading to a dropped basket, damage to the parts within, and hazardous spills of cleaning chemicals.

Why This Inspection is Mission-Critical

Understanding the consequences of a failed basket elevates the inspection from a simple task to a crucial part of your quality assurance protocol.

To Ensure Cleaning Efficacy

The entire purpose of the basket is to hold parts in a way that allows the cleaning medium to reach every surface. Damage or blockages directly compromise this function, leading to unreliable and unrepeatable results.

To Prevent Part Damage or Loss

For industries handling microelectronics, medical implants, or other precision components, the loss of a single part can be extremely costly. A compromised basket is a direct threat to these assets.

To Maintain Process Purity

Damaged PTFE can potentially shed microscopic particles into the cleaning bath, acting as a contaminant. Similarly, a compromised surface can trap soils from one batch and release them into the next, invalidating your process.

Understanding the Trade-offs: Repair vs. Replace

When damage is found, you are faced with a critical decision. The choice between repairing and replacing the basket has direct implications for safety and process integrity.

When to Repair

Minor cracks on non-structural surfaces can sometimes be repaired. This requires a specialized PTFE repair agent and meticulous surface preparation, including cleaning and roughening the damaged area.

Repair should only be considered a temporary solution for minor cosmetic issues. It is generally not recommended for mesh or primary load-bearing structures.

When to Replace

Replacement is the default, safest option. Any significant damage, such as large cracks, holes in the mesh, deformation, or loose handles, warrants immediate replacement.

The risk of process failure, part loss, or a safety incident from a failing basket almost always outweighs the cost of a new one.

Making the Right Choice for Your Goal

Your inspection criteria and subsequent actions should align directly with your process requirements and the value of the components being cleaned.

- If your primary focus is processing high-value micro-components: Treat any flaw in the mesh, no matter how small, as a critical failure requiring immediate replacement.

- If your primary focus is cleaning larger, robust parts: Prioritize structural integrity, handle security, and even weight distribution to prevent catastrophic basket failure.

- If your primary focus is maintaining a validated cGMP or cleanroom process: View any visible damage or degradation as a process deviation that necessitates immediate replacement and documentation.

Consistent inspection transforms a simple basket into a reliable instrument for repeatable, high-quality results.

Summary Table:

| Inspection Step | What to Check For | Why It's Critical |

|---|---|---|

| Structural Integrity | Cracks, holes, or deformation, especially at corners and joints. | Prevents loss of valuable parts and physical damage to components. |

| Mesh Condition | Clogging or debris blocking the mesh openings. | Ensures proper cleaning solution flow and prevents cross-contamination. |

| Component Security | Firmly attached handle and secure lids/latches. | Avoids safety hazards, spills, and dropped baskets. |

Ensure your lab's cleaning processes are reliable and contamination-free. A faulty PTFE basket can compromise your entire batch. KINTEK specializes in high-quality lab equipment and consumables, including durable PTFE cleaning baskets designed for precision and longevity. Our experts can help you select the right equipment to protect your valuable components and maintain process purity.

Contact us today to discuss your specific laboratory needs and ensure your cleaning protocols are built on a foundation of quality equipment. #ContactForm

Visual Guide

Related Products

- Custom PTFE Teflon Parts Manufacturer for Hollow Cleaning Basket and Rack Carrier

- Custom PTFE Teflon Parts Manufacturer Corrosion Resistant Cleaning Rack Flower Basket

- Custom Machined and Molded PTFE Teflon Parts Manufacturer for Laboratory ITO FTO Conductive Glass Cleaning Flower Basket

- Custom PTFE Teflon Parts Manufacturer for Centrifuge Tube Racks

- Custom PTFE Teflon Parts Manufacturer for Hollow Etching Flower Basket ITO FTO Developing Glue Removal

People Also Ask

- How should a PTFE cleaning basket be stored when not in use? Maximize Lifespan & Prevent Contamination

- What are the common specifications and shapes for PTFE cleaning baskets? Maximize Chemical Purity & Process Integrity

- What is the correct way to place items into a PTFE cleaning basket? Master the Art of Perfect, Repeatable Cleaning

- How do Teflon (PTFE) baskets facilitate glass thin-film leaching? Enhance Accuracy with Chemical Inertness

- What should be monitored during the cleaning process when using a PTFE cleaning basket? Ensure Reliable Results & Prevent Damage