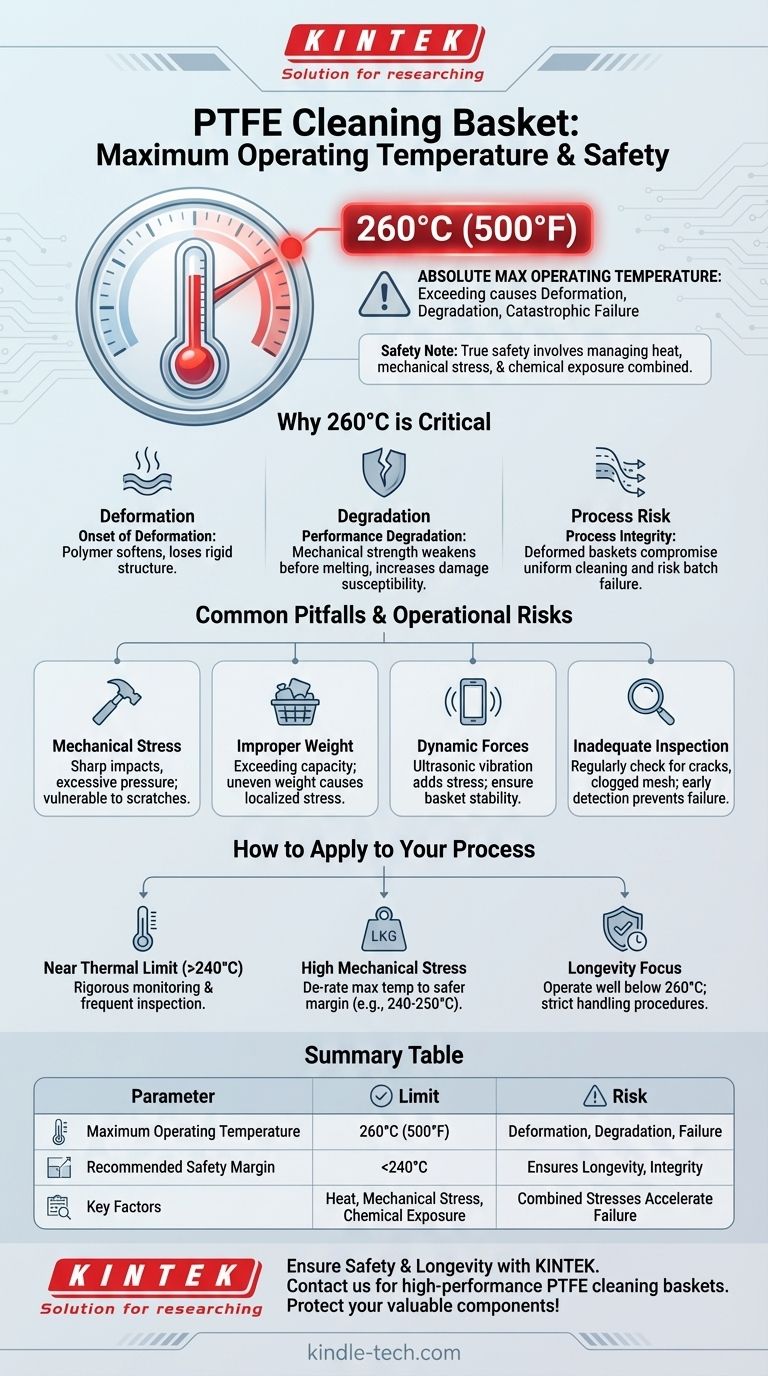

The definitive maximum operating temperature for a standard PTFE cleaning basket is 260°C (500°F). Exceeding this critical threshold will cause the material to deform, degrade in performance, and risk catastrophic failure of the basket, potentially damaging the valuable items inside.

While 260°C is the absolute thermal limit, true operational safety and longevity come from understanding that heat, mechanical stress, and chemical exposure work in combination. The real goal is to maintain the basket's structural integrity, not just to avoid melting it.

Why 260°C is the Critical Threshold

Polytetrafluoroethylene (PTFE) is prized for its exceptional chemical resistance and thermal stability. However, like any material, it has clear operational boundaries that must be respected to ensure a safe and repeatable cleaning process.

The Onset of Deformation

The 260°C limit is not arbitrary. It represents the point where the polymer begins to soften and lose its rigid structure. For a basket designed to hold and protect components, maintaining its shape is its primary function.

Performance Degradation

Even before visible melting occurs, temperatures approaching this limit can degrade the basket's mechanical strength. This makes it more susceptible to damage from impacts or the weight of its contents.

Protecting Your Process Integrity

A deformed or weakened basket can no longer guarantee uniform cleaning, as it may affect the flow of solutions or the positioning of parts. If a basket fails, it can compromise an entire batch of sensitive and expensive components.

Common Pitfalls and Operational Risks

Achieving the maximum lifespan from a PTFE basket involves more than just watching the thermometer. Physical handling and loading procedures are equally critical, especially when operating at elevated temperatures.

Mechanical Stress and Impact

Avoid subjecting the basket to sharp impacts or excessive pressure. PTFE is a relatively soft material, and high temperatures will only make it more vulnerable to scratches and gouges from items with sharp corners.

Improper Weight Distribution

Never exceed the basket's specified load capacity. Always distribute the weight of the items evenly to prevent localized stress points, which can lead to warping and deformation over time.

Ignoring Dynamic Forces

In processes like ultrasonic cleaning, the constant vibration adds another layer of stress. If you notice the basket shifting or moving excessively, stop the process immediately and readjust its position to ensure stability and cleaning efficacy.

Inadequate Inspection

Regular inspection is not optional. A consistent schedule, perhaps monthly or more often with heavy use, allows you to identify minor cracks, clogged mesh, or early signs of deformation before they lead to a complete failure. Minor damage can often be addressed with specialized PTFE repair agents.

How to Apply This to Your Process

Your specific operational parameters will determine how you should approach this temperature limit.

- If your process operates consistently near the thermal limit (>240°C): You must implement rigorous monitoring and frequent inspection protocols to catch the earliest signs of material degradation.

- If your process involves high mechanical stress (e.g., heavy parts, ultrasonic vibration): Consider de-rating the maximum temperature to a safer margin (e.g., 240-250°C) to account for the combined stresses on the material.

- If your primary focus is equipment longevity and process repeatability: Always operate well below the 260°C limit and enforce strict loading and handling procedures to eliminate premature failure.

Respecting these material limits is the key to ensuring a safe, reliable, and repeatable cleaning operation.

Summary Table:

| Parameter | Limit | Risk of Exceeding |

|---|---|---|

| Maximum Operating Temperature | 260°C (500°F) | Deformation, degradation, catastrophic failure |

| Recommended Safety Margin | <240°C | Ensures longevity and structural integrity |

| Key Factors | Heat, mechanical stress, chemical exposure | Combined stresses accelerate material failure |

Ensure the safety and longevity of your lab processes with the right equipment. At KINTEK, we specialize in high-performance lab equipment and consumables, including durable PTFE cleaning baskets designed for rigorous applications. Our experts can help you select the ideal basket for your specific temperature and stress requirements, ensuring reliable, repeatable results. Contact us today to discuss your laboratory needs and protect your valuable components!

Visual Guide

Related Products

- Custom PTFE Teflon Parts Manufacturer Corrosion Resistant Cleaning Rack Flower Basket

- Custom Machined and Molded PTFE Teflon Parts Manufacturer for Laboratory ITO FTO Conductive Glass Cleaning Flower Basket

- Custom PTFE Teflon Parts Manufacturer for Hollow Cleaning Basket and Rack Carrier

- Custom PTFE Teflon Parts Manufacturer for Conductive Glass Substrate Cleaning Rack

- Custom PTFE Teflon Parts Manufacturer for PTFE Containers

People Also Ask

- What is the procedure for using a PTFE cleaning basket? A 3-Step Guide for Flawless Results

- What is the correct way to place items into a PTFE cleaning basket? Master the Art of Perfect, Repeatable Cleaning

- How should a PTFE cleaning basket be cleaned before its initial use? A Critical First Step for Process Integrity

- What material is a PTFE cleaning basket made of? Unlocking Superior Chemical and Thermal Resistance

- What inspection should be performed on a PTFE cleaning basket before use? A 3-Step Protocol for Safe, Effective Cleaning