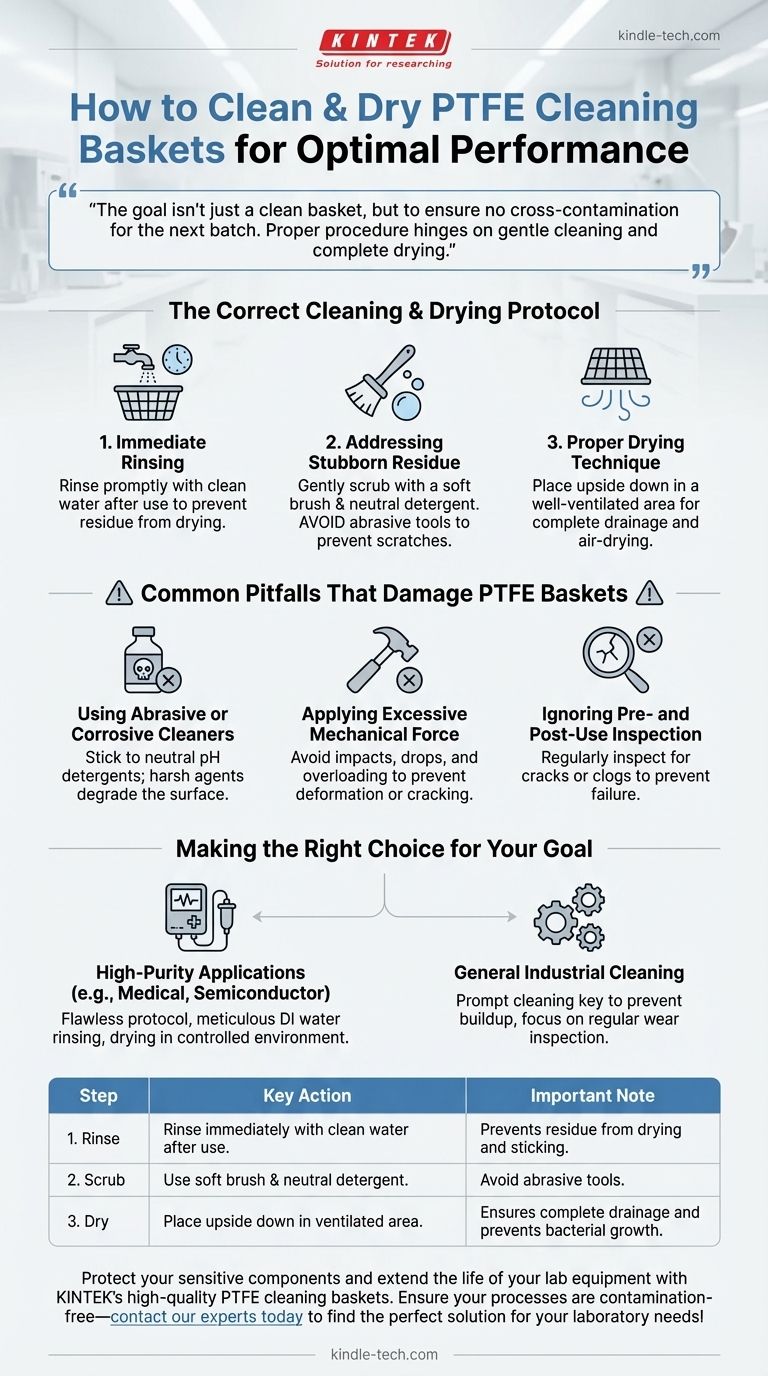

To properly clean and dry a PTFE cleaning basket, you must rinse it immediately after use with clean water to remove residual solutions. For tougher stains, gently scrub with a soft brush and a neutral detergent, then rinse thoroughly. To dry, place the basket upside down in a well-ventilated area, allowing it to drain and air-dry completely.

The goal of cleaning a PTFE basket isn't just to make the basket itself clean, but to ensure it doesn't cross-contaminate the next batch of critical components. Proper procedure hinges on gentle cleaning methods and complete drying to preserve the basket's integrity and prevent bacterial growth.

The Correct Cleaning and Drying Protocol

Following a consistent procedure is key to maintaining the performance and extending the service life of your PTFE equipment. The material's non-stick properties simplify the process, but attention to detail is crucial.

Step 1: Immediate Rinsing

As soon as the basket is removed from the cleaning equipment, it should be promptly rinsed with clean water.

This immediate action prevents residual cleaning solutions, oils, or particulates from drying onto the surface, which can make them much more difficult to remove later.

Step 2: Addressing Stubborn Residue

For any remaining stains or buildup, use a soft brush and a neutral detergent.

Gently scrub the affected areas. Avoid using hard or metal brushes, as these will scratch the PTFE surface. Scratches can become sites where contaminants accumulate in future cleaning cycles.

After scrubbing, rinse the basket thoroughly to ensure all detergent is washed away.

Step 3: Proper Drying Technique

Once clean, turn the basket upside down and place it in a dry, ventilated location.

This orientation allows water to drain completely from the mesh and surfaces. Proper air circulation is essential for complete drying and is the most effective way to prevent the growth of mold or bacteria.

Common Pitfalls That Damage PTFE Baskets

The chemical resistance of PTFE can create a false sense of invulnerability. However, the material is mechanically soft and requires careful handling to avoid damage that compromises its effectiveness.

Using Abrasive or Corrosive Cleaners

Never use harsh, corrosive cleaners or abrasive powders. While PTFE is highly resistant to chemicals, aggressive agents can eventually degrade the material's surface integrity.

Stick to neutral pH detergents, which are effective enough for cleaning without posing a risk to the basket's structure.

Applying Excessive Mechanical Force

Avoid forceful impacts, dropping the basket, or scraping it against the inner walls of cleaning tanks. PTFE can be scratched, dented, or cracked by mechanical shock.

Similarly, never exceed the basket's maximum load capacity. Overloading and uneven weight distribution can cause localized stress, leading to deformation or failure over time.

Ignoring Pre- and Post-Use Inspection

Before each use, perform a quick visual inspection for cracks, holes, or clogged mesh. After cleaning and drying, inspect it again.

Identifying minor damage early allows for potential repair with a specialized PTFE agent and prevents a catastrophic failure during a critical cleaning process.

Making the Right Choice for Your Goal

Your cleaning and maintenance protocol should align with the sensitivity of the parts you are processing.

- If your primary focus is high-purity applications (e.g., medical, semiconductor): Your protocol must be flawless, with meticulous rinsing using deionized water and drying in a controlled environment to eliminate any risk of cross-contamination.

- If your primary focus is general industrial cleaning: Prompt cleaning after use is key to preventing buildup and maximizing the basket's lifespan, with a focus on regular inspection for mechanical wear and tear.

Consistent, gentle care is the key to ensuring your PTFE basket remains a reliable tool in your cleaning process.

Summary Table:

| Step | Key Action | Important Note |

|---|---|---|

| 1. Rinse | Rinse immediately with clean water after use. | Prevents residue from drying and sticking. |

| 2. Scrub | Use a soft brush and neutral detergent for stains. | Avoid abrasive tools to prevent surface scratches. |

| 3. Dry | Place upside down in a well-ventilated area. | Ensures complete drainage and prevents bacterial growth. |

Protect your sensitive components and extend the life of your lab equipment with KINTEK's high-quality PTFE cleaning baskets. Our baskets are designed for durability and purity, making them ideal for critical applications in medical, semiconductor, and industrial labs. Ensure your processes are contamination-free—contact our experts today to find the perfect solution for your laboratory needs!

Visual Guide

Related Products

- Custom PTFE Teflon Parts Manufacturer for Hollow Cleaning Basket and Rack Carrier

- Custom PTFE Teflon Parts Manufacturer Corrosion Resistant Cleaning Rack Flower Basket

- Custom PTFE Teflon Parts Manufacturer for PTFE Containers

- Custom Machined and Molded PTFE Teflon Parts Manufacturer for Laboratory ITO FTO Conductive Glass Cleaning Flower Basket

- Custom PTFE Teflon Parts Manufacturer for Centrifuge Tube Racks

People Also Ask

- How do Teflon (PTFE) baskets facilitate glass thin-film leaching? Enhance Accuracy with Chemical Inertness

- What should be monitored during the cleaning process when using a PTFE cleaning basket? Ensure Reliable Results & Prevent Damage

- What material is a PTFE cleaning basket made of? Unlocking Superior Chemical and Thermal Resistance

- What precautions should be taken regarding the physical handling and loading of a PTFE cleaning basket? Prevent Damage and Ensure Process Integrity

- What are the common specifications and shapes for PTFE cleaning baskets? Maximize Chemical Purity & Process Integrity