At their core, carbon nanotubes are special because they combine multiple world-class properties into a single, microscopic structure. They possess the strength of diamond, the electrical conductivity of copper, and the thermal conductivity of graphite, all while being incredibly lightweight and flexible. This unique combination is a direct result of their atomic structure: a seamless, rolled-up sheet of graphene.

The true significance of nanotubes isn't just one exceptional property, but the unprecedented synergy of having extreme strength, conductivity, and lightness all packaged within a single, stable nanoscale material.

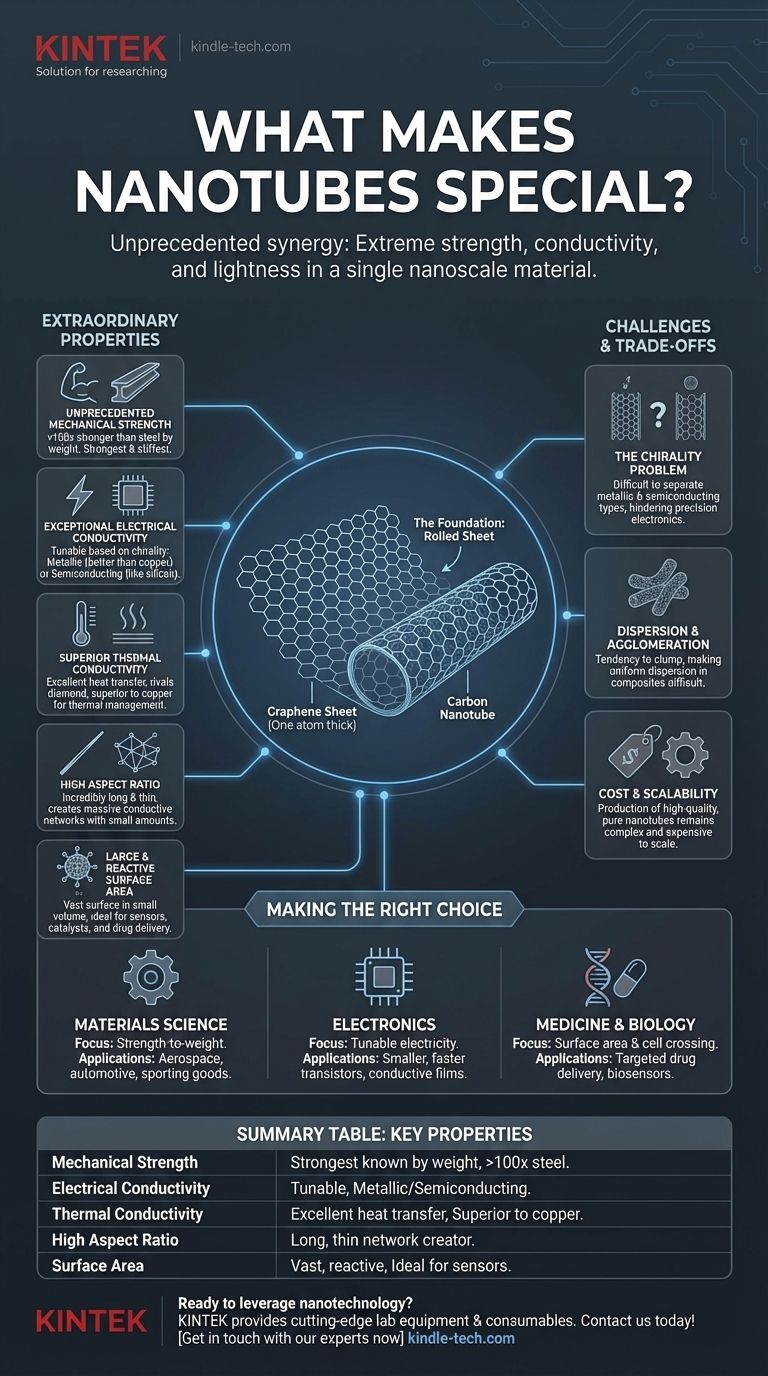

The Foundation: A Rolled Sheet of Graphene

To understand a nanotube's power, you must first visualize its structure. Imagine a sheet of chicken wire made of carbon atoms, one atom thick. This is a material called graphene.

What is a Carbon Nanotube?

A carbon nanotube is simply one of these graphene sheets rolled up into a seamless, hollow cylinder.

This simple act of rolling the sheet is what unlocks its extraordinary collection of properties, dictating everything from its strength to how it conducts electricity.

The Extraordinary Properties of Nanotubes

The unique cylindrical arrangement of carbon atoms gives rise to a set of capabilities that far exceed those of conventional bulk materials.

Unprecedented Mechanical Strength

Carbon nanotubes are the strongest and stiffest materials yet discovered in terms of tensile strength and elastic modulus.

A single nanotube is estimated to be over 100 times stronger than steel of the same weight. This has made them a candidate for revolutionary applications like the theoretical "space elevator."

Exceptional Electrical Conductivity

The way the graphene sheet is "rolled" (its angle, or chirality) determines its electrical properties.

Depending on this structure, a nanotube can behave either as a metallic conductor, more conductive than copper, or as a semiconductor, like the silicon used in all modern electronics. This tunability is a key feature.

Superior Thermal Conductivity

Nanotubes are excellent thermal conductors, efficiently transferring heat along their length.

Their ability to dissipate heat rivals that of diamond and is far superior to metals like copper, making them ideal for managing heat in microelectronics and other systems.

High Aspect Ratio

Nanotubes are incredibly long and thin, a property known as a high aspect ratio.

This allows a very small amount of nanotubes to create a massive conductive or reinforcing network when mixed into a composite material, dramatically improving its properties.

Large and Reactive Surface Area

The outer surface of a nanotube is composed entirely of carbon atoms, creating a vast surface area in a small volume.

This makes them highly effective as sensors, catalysts, and vehicles for drug delivery, as molecules can be attached to their surfaces.

Understanding the Trade-offs and Challenges

Despite their revolutionary potential, significant practical hurdles have slowed the widespread adoption of carbon nanotubes.

The Chirality Problem

Current manufacturing methods produce a mix of nanotubes with different chiralities, resulting in a batch that contains both metallic and semiconducting types.

Separating these types is a major challenge, hindering their use in precision electronics where uniform properties are essential.

Dispersion and Agglomeration

Due to powerful intermolecular forces, nanotubes tend to clump together in bundles.

This makes them difficult to disperse evenly into other materials like polymers or metals, which is necessary to impart their strength and conductivity to the composite.

Cost and Scalability

While prices have decreased, the production of high-quality, pure carbon nanotubes remains a complex and expensive process.

Scaling up production to industrial levels required for mass-market applications like structural materials remains a significant economic and engineering challenge.

Making the Right Choice for Your Goal

The "special" nature of nanotubes is best understood by their potential impact across different fields. Their utility depends entirely on which of their properties you wish to leverage.

- If your primary focus is materials science: Their unrivaled strength-to-weight ratio is key for creating ultra-strong, lightweight composites for aerospace, automotive, and sporting goods.

- If your primary focus is electronics: Their tunable electrical properties offer the potential for smaller, faster, and more energy-efficient transistors, wires, and transparent conductive films.

- If your primary focus is medicine and biology: Their high surface area and ability to cross cell membranes make them promising candidates for targeted drug delivery, bio-imaging, and advanced biosensors.

Ultimately, carbon nanotubes represent a foundational material with the potential to redefine the performance limits in nearly every field of science and engineering.

Summary Table:

| Property | Description | Key Advantage |

|---|---|---|

| Mechanical Strength | Strongest known material by weight | Over 100x stronger than steel |

| Electrical Conductivity | Can be metallic or semiconducting | Tunable for electronics applications |

| Thermal Conductivity | Excellent heat transfer along length | Superior to copper for thermal management |

| High Aspect Ratio | Long, thin structure creates large networks | Small amounts dramatically enhance composites |

| Surface Area | Vast reactive surface in small volume | Ideal for sensors, catalysts & drug delivery |

Ready to leverage nanotechnology in your research?

At KINTEK, we specialize in providing cutting-edge lab equipment and consumables that empower scientists and engineers working with advanced materials like carbon nanotubes. Whether you're developing next-generation composites, electronics, or biomedical applications, our solutions support your innovation from research to production.

Contact us today to discuss how our expertise can enhance your nanotechnology projects. Let's build the future of materials science together!

Get in touch with our experts now

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What function does CVD equipment serve in rhodium-modified coatings? Achieve Deep Diffusion and Microstructural Precision

- What are the main advantages of Chemical Vapor Deposition (CVD)? Achieve Precision Coating for Complex Geometries

- How does chirality affect carbon nanotubes? It Determines If They Are Metal or Semiconductor

- How high of temperature do carbon nanotubes in air have the ability to sustain? Understanding the Oxidation Limit

- What are the advantages of industrial CVD for solid boriding? Superior Process Control and Material Integrity