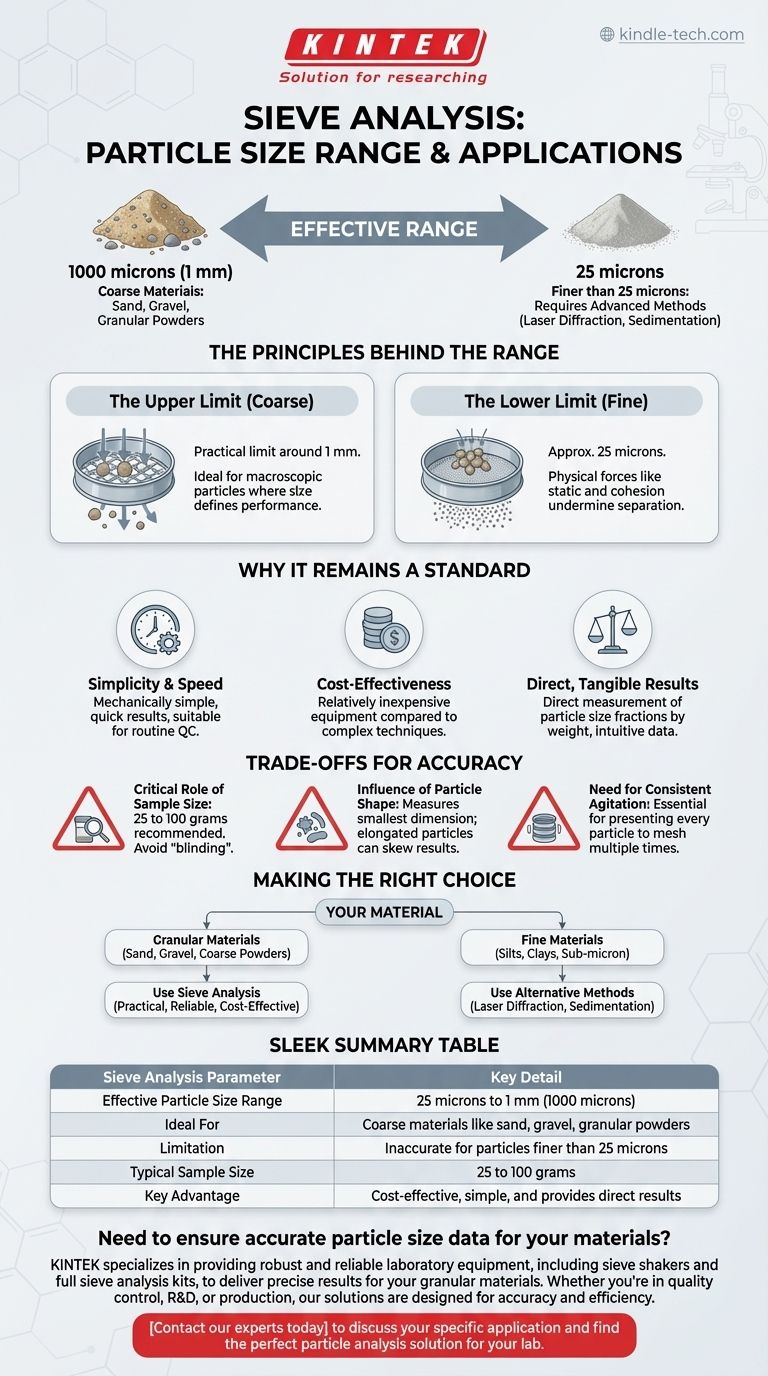

At its core, sieve analysis is a foundational and widely trusted technique for determining particle size distribution. It is most effective and accurate for materials with particle sizes ranging from approximately 1 millimeter (1000 microns) down to about 25 microns.

While sieve analysis is valued for its simplicity and low cost, its accuracy is confined to a specific range of coarser particles. For materials finer than 25 microns, the physical limitations of sieving require the use of more advanced analytical methods.

The Principles Behind the Sieve Analysis Range

Sieve analysis operates on a straightforward principle: mechanically sorting particles by passing them through a series of screens with progressively smaller mesh openings. This direct, physical approach defines both its strengths and its boundaries.

The Upper Limit: Coarse Materials

The practical upper limit, often around 1 mm, is determined by the coarsest sieve in a given stack. This makes it ideal for analyzing materials like sand, gravel, and many granular powders where macroscopic particle size is a critical performance factor.

The Lower Limit: Fine Particles

The effective lower limit is approximately 25 microns. Below this threshold, physical forces begin to undermine the separation process. Fine particles are more susceptible to static electricity and cohesion (clumping together), which prevents them from passing through the mesh openings correctly.

Why This Method Remains a Standard

Despite its limitations, sieve analysis is a cornerstone of material science for several key reasons. Understanding these helps clarify when it is the appropriate choice.

Simplicity and Speed

The procedure is mechanically simple, requiring minimal operator skill or experience to perform correctly. Results can be obtained quickly, making it suitable for routine quality control.

Cost-Effectiveness

Compared to more complex techniques like laser diffraction, the equipment for sieve analysis is relatively inexpensive. This accessibility makes it a practical option for a wide range of industries.

Direct, Tangible Results

Sieve analysis provides a direct measurement of particle size fractions by weight. The results are intuitive and easily understood, representing the physical reality of the material.

Understanding the Trade-offs for Accuracy

The reliability of sieve analysis depends entirely on acknowledging its inherent limitations and controlling key variables during the test.

The Critical Role of Sample Size

Using the correct sample size is paramount. A sample of 25 to 100 grams is typically recommended. If the sample is too large, it can overload the sieve, a phenomenon known as "blinding," where particles cover the mesh and prevent others from having a chance to pass through.

The Influence of Particle Shape

Sieve analysis measures the smallest dimension of a particle that can pass through an opening. Elongated or flat particles may pass through end-on but would be stopped if oriented differently, which can skew the perceived size distribution compared to more spherical particles.

The Need for Consistent Agitation

Proper agitation (shaking or vibrating) is essential to ensure every particle is presented to the sieve openings multiple times and from multiple angles. Inconsistent agitation is a common source of inaccurate and non-repeatable results.

Making the Right Choice for Your Material

Your choice of particle size analysis method must be guided by the nature of your material and the data you need to obtain.

- If your primary focus is on granular materials like sand, gravel, or coarse powders: Sieve analysis is the most practical, reliable, and cost-effective method for your needs.

- If your material contains fine silts, clays, or is in the sub-micron range: You must use an alternative method like laser diffraction or sedimentation, as sieve analysis will not produce accurate results.

Ultimately, matching your analysis technique to your expected particle size range is the first step toward achieving meaningful and actionable data.

Summary Table:

| Sieve Analysis Parameter | Key Detail |

|---|---|

| Effective Particle Size Range | 25 microns to 1 mm (1000 microns) |

| Ideal For | Coarse materials like sand, gravel, granular powders |

| Limitation | Inaccurate for particles finer than 25 microns |

| Typical Sample Size | 25 to 100 grams |

| Key Advantage | Cost-effective, simple, and provides direct results |

Need to ensure accurate particle size data for your materials?

KINTEK specializes in providing robust and reliable laboratory equipment, including sieve shakers and full sieve analysis kits, to deliver precise results for your granular materials. Whether you're in quality control, R&D, or production, our solutions are designed for accuracy and efficiency.

Contact our experts today to discuss your specific application and find the perfect particle analysis solution for your lab.

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Single Horizontal Jar Mill

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- What is the purpose of using a 400-mesh standard sieve? Optimize Carbon Powder for High-Performance Cathodes

- What size sieves are used in sieve analysis? A Guide to Mesh, Frame, and Standard Selection

- What is the industrial application of sieve? Master Particle Control for Quality Assurance

- What are the advantages of sieve test? Achieve Fast, Cost-Effective Particle Analysis

- What are the sieve used in laboratory? A Guide to Choosing the Right Sieve for Accurate Particle Analysis

- How do you use sieving method? A Step-by-Step Guide to Accurate Particle Separation

- How accurate is a test sieve? Ensure Reliable Particle Size Analysis

- What is the laboratory test for sieve analysis? A Step-by-Step Guide to Particle Size Distribution